Multilayer structure liquid crystal optical element and manufacturing method thereof

A technology of liquid crystal optics and multi-layer structure, which is applied in optics, nonlinear optics, instruments, etc., can solve the problems of slow response speed and achieve the effects of small number of electrodes, easy processing, and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Preferred embodiments of the multilayer liquid crystal optical element and its manufacturing method for carrying out the present invention will be described with reference to the drawings.

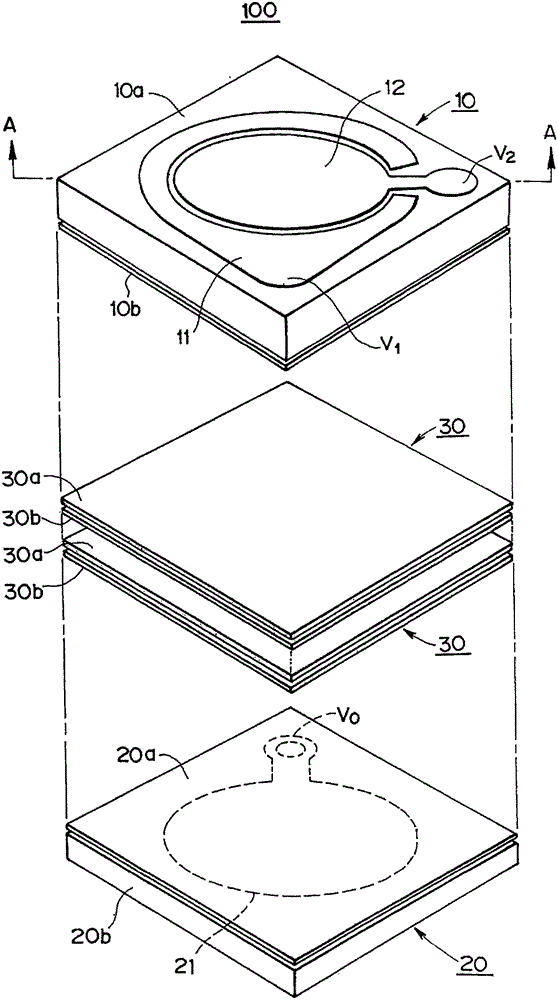

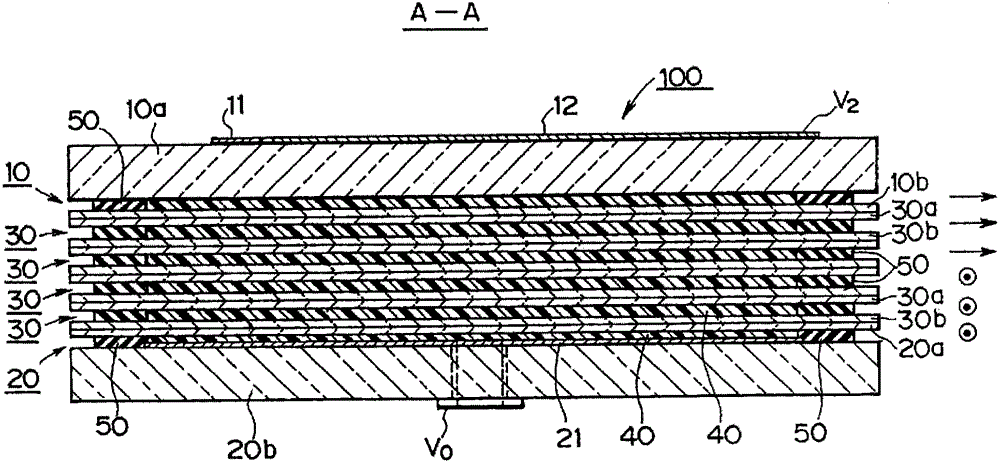

[0039] figure 1 It is an exploded view showing the structure of the multilayer liquid crystal optical element 100 of the first embodiment. figure 2 It is a cross-sectional view along line A-A showing the structure of the multilayer liquid crystal optical element 100 .

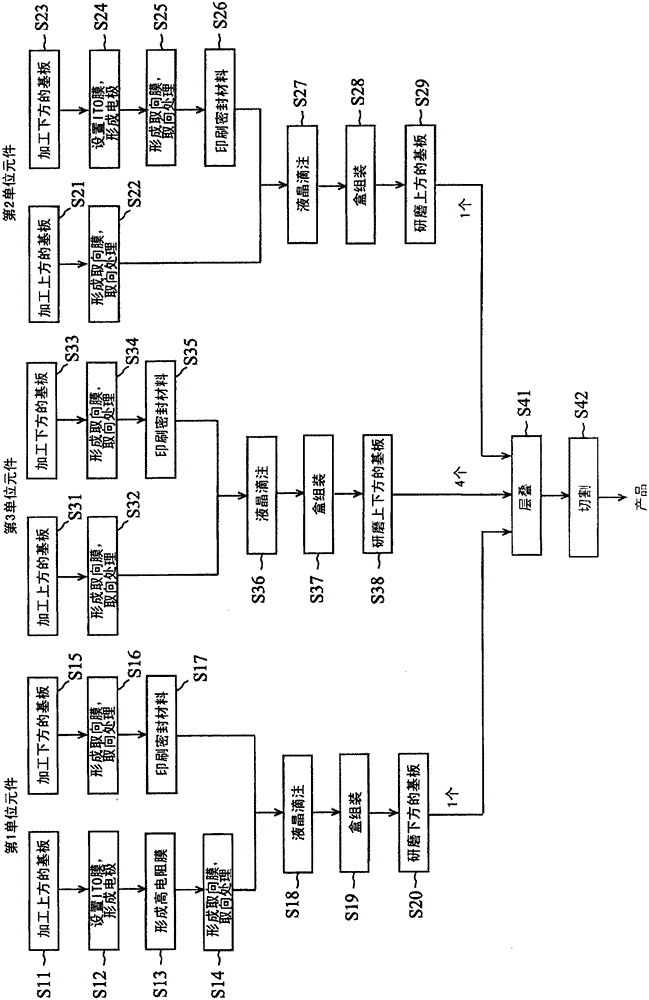

[0040] Such as figure 1 , figure 2 As shown, the multilayer liquid crystal optical element 100 includes a first unit element 10, a second unit element 20, and a plurality (four in this example) of third unit elements 30. Four third unit elements 30 are provided and stacked between one unit element 10 and second unit element 20 . In addition, the alignment directions of the liquid crystals of the first unit cell 10 and the upper two third unit cells 30 and the alignment directions of the liquid crystals of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com