Filter membrane of plasma display panel capable of improving light-room contrast and preparation method of filter membrane

A plasma display, bright room contrast technology, applied in the field of filter films, can solve the problems of many transparent polymer resin substrates and pressure-sensitive adhesives, limiting the visible light transmittance of filter films, and long process routes, etc. Light transmittance and high bright room contrast, improved bright room contrast, less process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

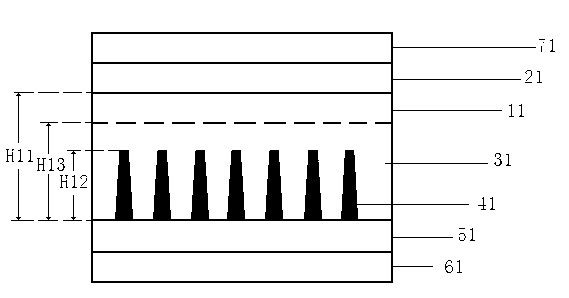

[0020] Embodiment 1: as image 3 As shown, the plasma display filter film includes a substrate 11, one surface of the substrate 11 is provided with an anti-reflection (AR) film layer 21, and the substrate 11 is provided with stripe pattern grooves, A black filler 41 is provided inside the stripe pattern groove, a Color-PSA adhesive film layer 51 is arranged outside the stripe pattern groove, and the stripe pattern groove is arranged on the substrate 11 Between the Color-PSA adhesive film layer 51, the substrate 11 is transparent, the stripe pattern groove is a trapezoid gradually narrowing from the outside to the inside, and the anti-reflection ( AR) The surface of the film layer 21 is provided with a protective film layer 71, the surface of the Color-PSA adhesive film layer 51 is provided with a release film layer 61, and the composition of the Color-PSA adhesive film layer 51 includes UV absorber, near-infrared light-absorbing dye, neon yellow light-absorbing dye, toning dy...

Embodiment 2

[0024] like Figure 4 As shown, the plasma display filter film includes a substrate 12, one surface of the substrate 12 is provided with an anti-reflection (AR) film layer 22, and the substrate 12 is provided with a stripe pattern groove, A black filler 42 is provided inside the stripe pattern groove, a Color-PSA adhesive film layer 52 is arranged outside the stripe pattern groove, and the stripe pattern groove is arranged on the substrate 12 Between the Color-PSA adhesive film layer 52, the substrate 12 is transparent, the stripe pattern groove is a triangle that gradually narrows from the outside to the inside, and the anti-reflection ( AR) The surface of the film layer 22 is provided with a protective film layer 72, the surface of the Color-PSA adhesive film layer 52 is provided with a release film layer 62, and the composition of the Color-PSA adhesive film layer 52 includes UV absorber, near-infrared light-absorbing dye, neon yellow light-absorbing dye, toning dye and ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com