Laser-induced breakdown spectroscopy measurement method for element content of powdery substance

A laser-induced breakdown and element content technology, applied in the field of atomic emission spectrometry, can solve the problems of reducing the running speed of the measurement system, difficult to achieve online measurement, complex system, etc., to improve the detection limit, reduce the detection limit, strong optical signal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

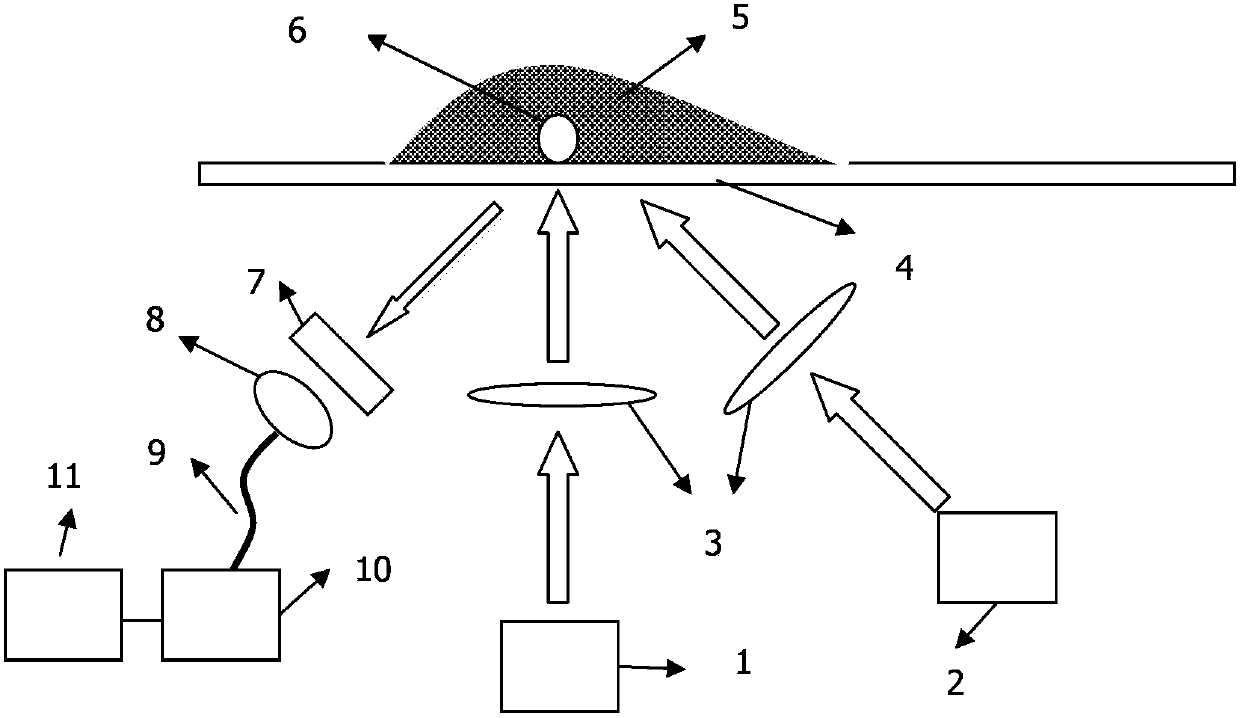

[0031] Taking the measurement of carbon in coal by LIBS as an example, the measurement method of laser-induced breakdown spectroscopy for powdery material components is described.

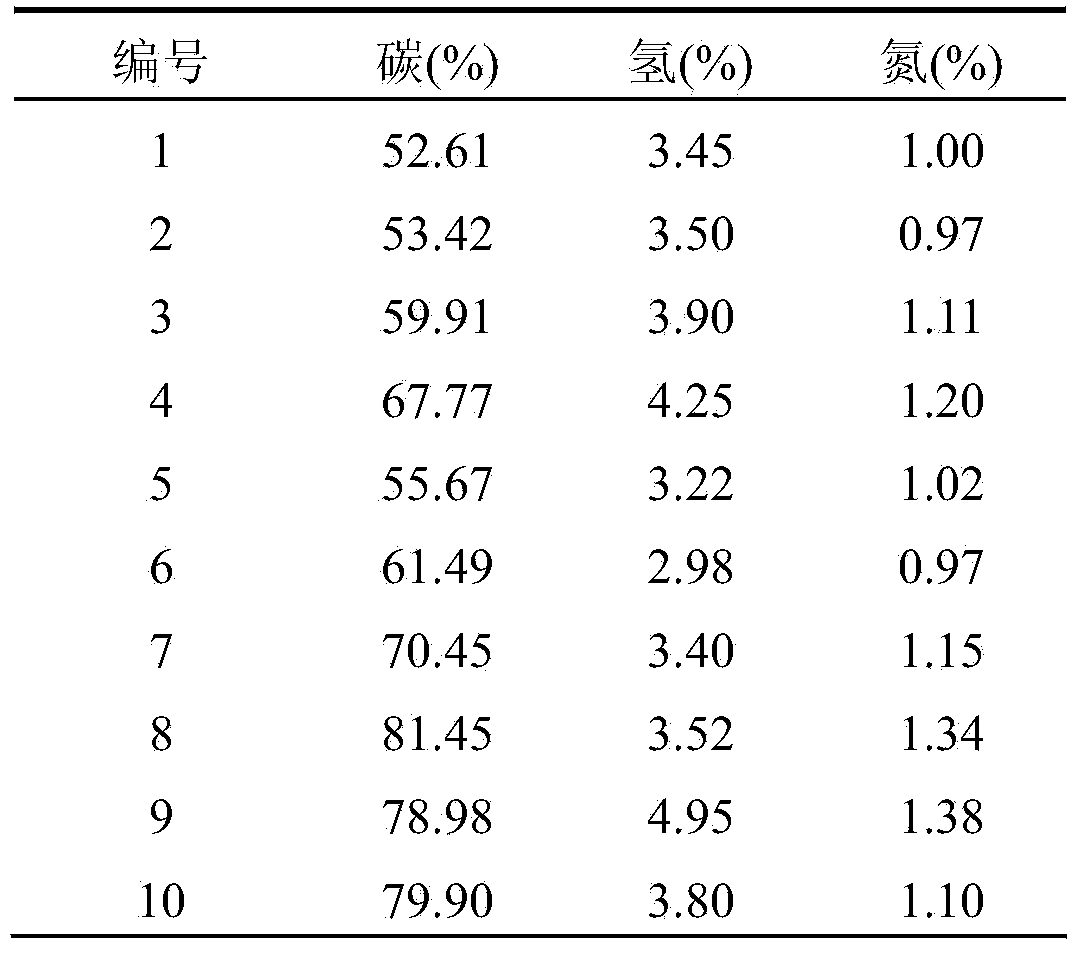

[0032] 1) Set the carbon element to be measured in the coal sample as the target element, first use ten kinds of coal samples with known mass concentrations of each element as calibration samples, and the mass concentrations of the main elements of each coal sample are shown in Table 1; The carbon concentration of the calibration sample is recorded as C 1 、C 2 、C 3 ...;

[0033] Table 1. Composition of standard coal samples

[0034]

[0035] 2) Select the first one from a group of calibration samples in step 1) and spread it on the transparent glass tray 4;

[0036] 3) Detection by laser-induced breakdown spectroscopy system: two pulse lasers are used, the first pulse laser 1 and the second pulse laser 2 are placed under the glass tray, and the positions of the two pulse lasers are not colli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com