Pressure container pressure resistance test process and auxiliary tools thereof

A pressure test, pressure vessel technology, applied in the application of stable tension/pressure to test the strength of materials, by detecting the appearance of fluid at the leak point, and using liquid/vacuum for liquid tightness measurement, etc., can solve the problem of low efficiency. , poor safety and high cost, to achieve the effect of reducing manufacturing cost, improving production efficiency and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

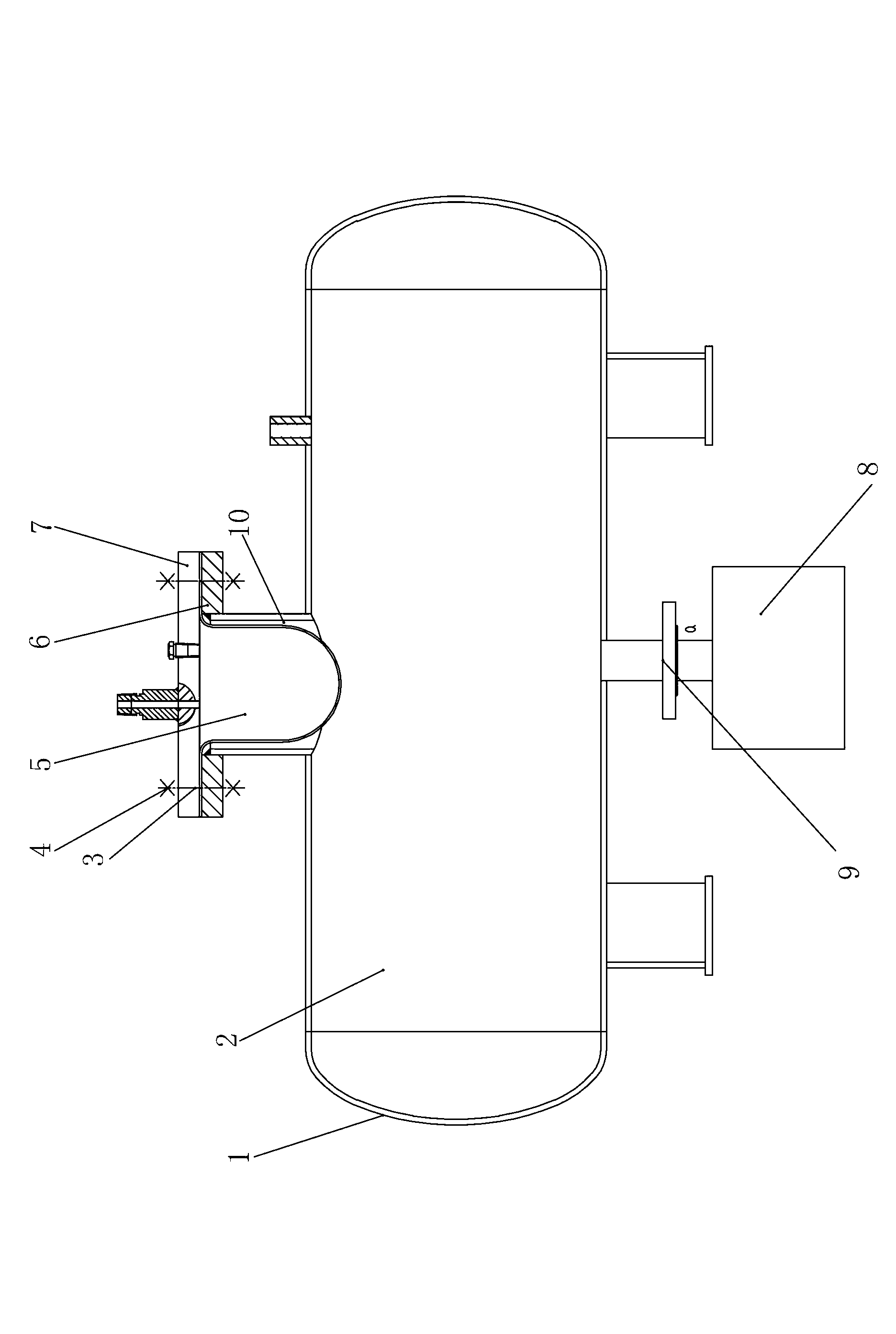

[0026] The present invention adds a pressurized chamber 5 and a storage container 8 that are matched with the original test tooling, and the pressurized chamber 5 and the storage container 8 are auxiliary tooling; the step of installing the pressurized chamber is added in the process, and different pressure test liquids are filled in different volume cavities Medium, the test volume body chamber 2 is filled with a volatile clean pressure test medium "dichlorofluoroethane (R141b)", and the pressurized chamber 5 is filled with water.

[0027] A pressurized chamber 5 is installed at the liquid inlet 10 of the original test vessel 1, and the pressurized chamber 5 divides the volume of the test vessel 1 into two volume chambers, one is the test volume body chamber 2, and the other is a pressurized chamber 5. The pressurized chamber 5 is compressed between the liquid inlet flange 6 and the flange cover 7 by fastening bolts 3 and nuts 4; a storage container 8 is set under the drain po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com