Control method of sounding rod to follow up charge level

A control method and material level technology, applied to furnaces, inspection devices, blast furnace details, etc., can solve the problems of increased measurement error, too small tension setting, calipers, etc., and achieve the effect of maintaining tension and avoiding buried rulers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

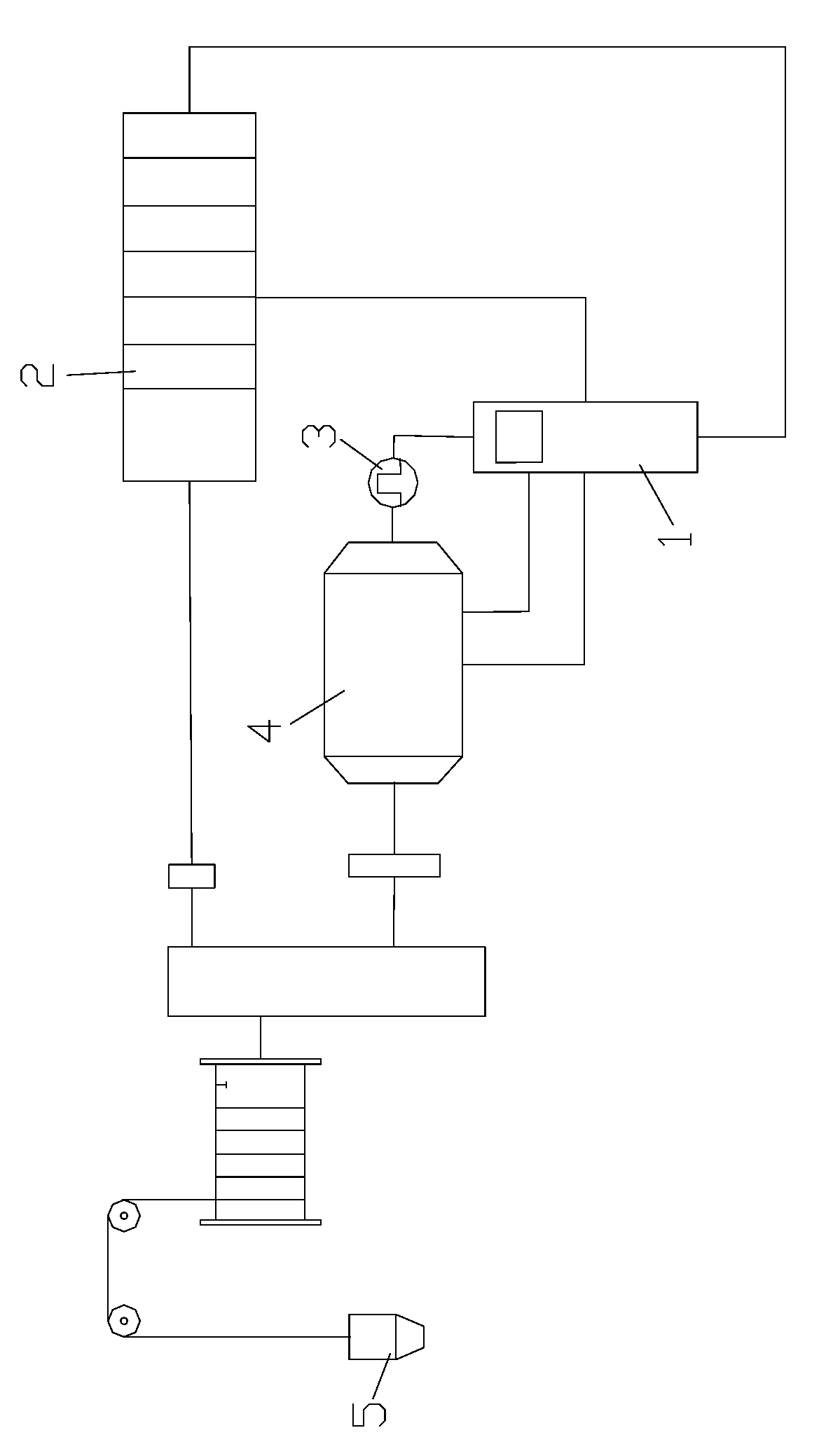

[0014] Such as figure 1 and figure 2 As shown in , the present invention relates to a method for controlling the probe following the material level, the frequency converter 1 is used as the core control unit to complete the work of setting the scale, following the material level and lifting the scale, and the PLC controller 2 is used as the command issuing unit, Communicate with the frequency converter 2 through hard wiring or bus, send a command to the frequency converter 2 to start measurement, and the incremental encoder 3 measures the actual speed of the motor 4, according to the following specific steps:

[0015] (1 probe lowering stage

[0016] Inverter 1 releases the brake and adopts speed control to make probe 5 descend at a constant speed. At this time, the descending speed of probe 1 is set to Setpn1, the direction is downward, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com