Base adhesive and preparation method thereof

A technology of base glue and waste rubber, which is applied in the field of polymer materials and its preparation, can solve problems such as unresolved environmental protection substantive problems, air pollution, etc., and achieve the effects of meeting environmental protection, low cost, and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

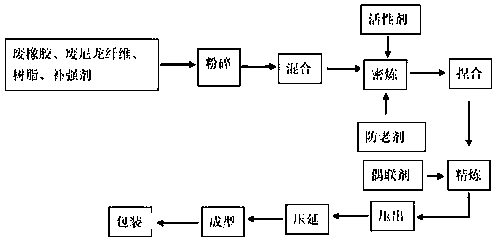

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the base glue of this embodiment, it is made through the following steps:

[0028] (1) Pulverization: Pulverize 50kg of waste rubber, 30kg of waste nylon fiber, 1kg of phenolic resin, and 2kg of N220 reinforcing agent;

[0029] (2) Mixing: Mix the pulverized materials evenly, the mixing temperature is 60°C, and the pressure is 5000 MPa;

[0030] (3) Internal mixing: add 3kg of activator ZnO and 3kg of anti-aging agent A to the mixed material for internal mixing. The processed material is intensively mixed under the action of the rotor of the internal mixer, and the large agglomerates are broken and gradually refined. The active agent ZnO and anti-aging agent A adhere to the surface of the material in the internal mixer until it is coated. , due to shearing and extrusion, the banburying material is gradually softened;

[0031] (4) Kneading: Put the materials that have been banburyed and have a certain viscosity into the kneader, and use mechan...

Embodiment 2

[0038] The preparation method of the base glue of this embodiment, it is made through the following steps:

[0039] (1) Pulverization: Pulverize 70kg of waste rubber, 40kg of waste nylon fiber, 5kg of phenolic resin, and 10kg of N330 reinforcing agent;

[0040] (2) Mixing: Mix the pulverized materials evenly, the mixing temperature is 80°C, and the pressure is 6000 MPa;

[0041] (3) Banburying: add 8kg of activator stearic acid and 6kg of antiaging agent D to the mixed materials and banburying, the banburying temperature is 150°C, the pressure is 6500 MPa, the time is 10min, the active agent stearic acid, antiaging agent Agent D and the mixed materials are intensively mixed under the action of the rotor of the internal mixer, and the large lumps are broken and gradually refined, and the active agent stearic acid and anti-aging agent D are attached to the surface of the material in the internal mixer until they are Coating, in the process of mixing, due to shearing and extrusi...

Embodiment 3

[0049] The preparation method of the base glue of this embodiment, it is made through the following steps:

[0050] (1) Pulverization: Pulverize 60kg of waste rubber, 34kg of waste nylon fiber, 2kg of polyester resin, and 4kg of N550 reinforcing agent;

[0051] (2) Mixing: Mix the pulverized materials evenly, the mixing temperature is 65°C, and the pressure is 5200 MPa;

[0052](3) Mixing: add 5kg of amine activator and 4kg of anti-aging agent RD to the mixed material. Mixing at 120°C, pressure of 6000 MPa, and 5 minutes, amine activator, anti-aging agent and The mixed material is intensively mixed under the action of the rotor of the internal mixer, and the large lumps are broken and gradually refined. The amine activator and anti-aging agent adhere to the surface of the material in the internal mixer until it is covered. During the process, due to shearing and extrusion, the banburying materials are gradually softened;

[0053] (4) Kneading: Add the materials that have bee...

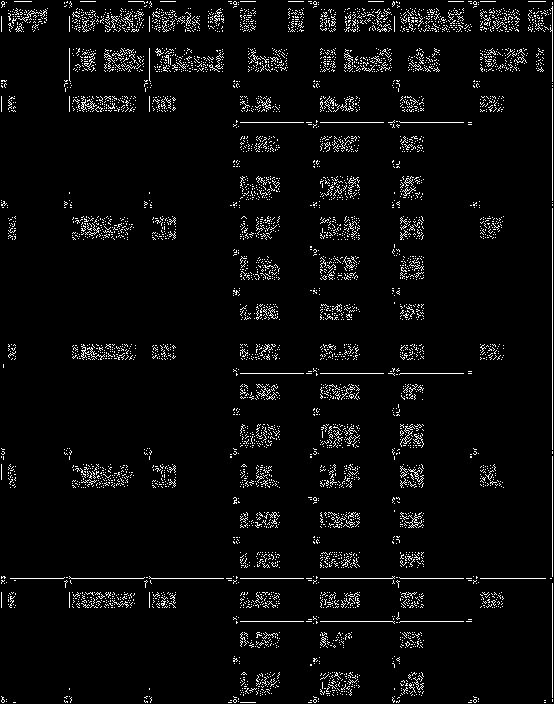

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com