Reciprocating type machine grinding tool

A reciprocating and grinding tool technology, which is applied in the direction of grinding/polishing hand tools, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of high work intensity, low efficiency and high cost of manual grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

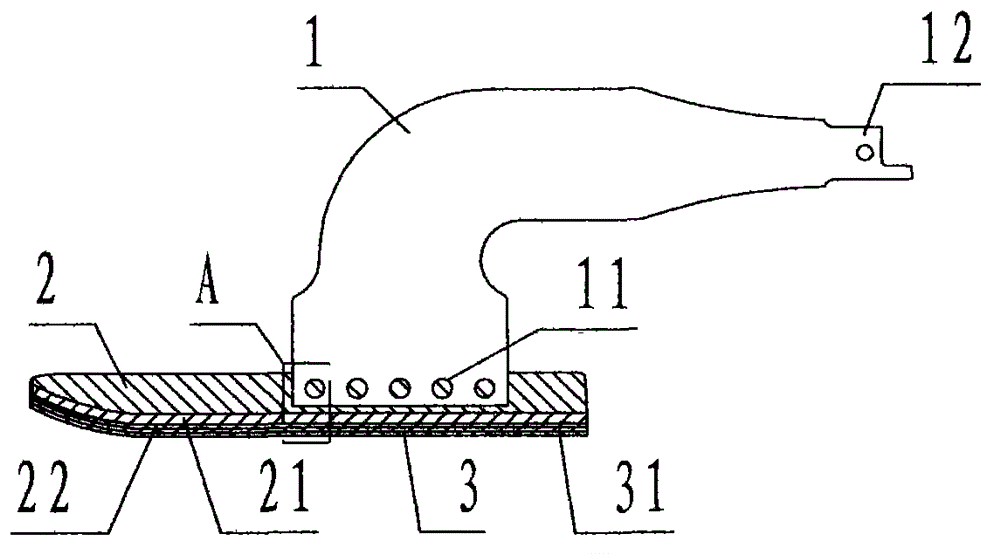

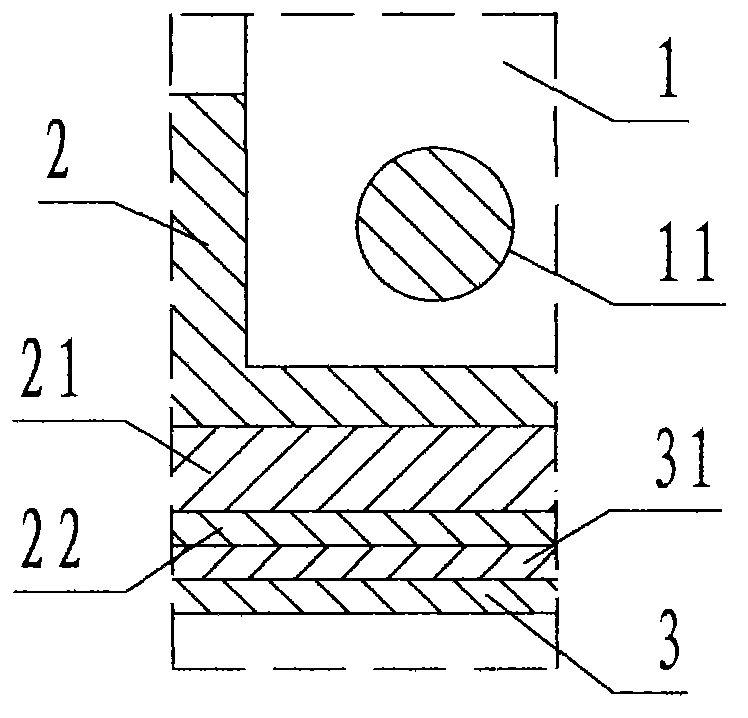

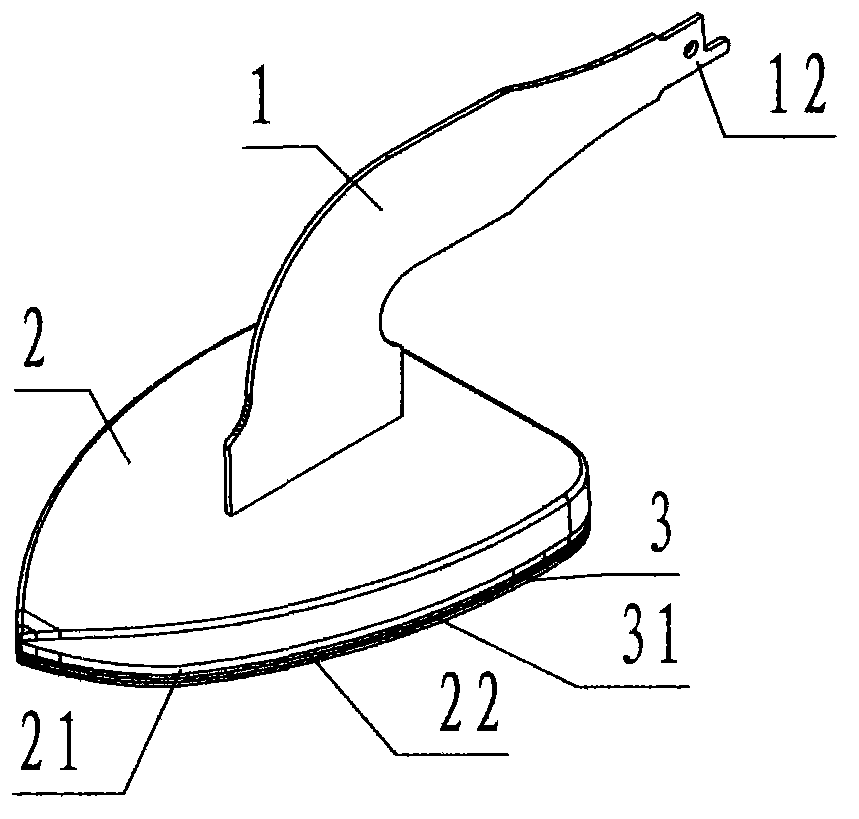

[0017] refer to Figure 1 ~ Figure 4 , a reciprocating machine abrasive tool of the present invention, comprising a connecting handle 1, a carrier plate 2, and an emery cloth 3, wherein: the connecting handle 1 is a Γ-shaped structure composed of a vertical foot on the left and a cross arm on the right. Sheet-shaped steel member, the bottom of the vertical foot of the connecting handle 1 is provided with five circular through holes arranged horizontally and uniformly called the embedded holes 11; the right end of the cross arm of the connecting handle 1 is provided with A joint 12 adapted to the saw blade chuck of the reciprocating electric saw, the joint 12 is finger-shaped and provided with a circular through hole;

[0018] The carrier plate 2 is a circular arc isosceles triangle whose two hypotenuses are circular arcs when viewed from above, and is a hard plastic member in the shape of an iron board; an elastic layer 21 of foamed plastic is provided under the carrier plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com