Pattern fixing rack for casting and molding

A technology for fixing frames and shapes, which is applied to casting and molding equipment, molding boxes, manufacturing tools, etc., can solve the problems of increasing the cost of molding tooling, increasing the weight of overturning boxes, and overweight safety risks, achieving cost savings, simple fixing brackets, and Dimensionally accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

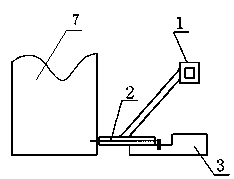

[0014] A pattern fixing frame for casting molding, such as figure 1 Shown: it comprises a square spacer 3 that one end is high and the other end is low, and the low end of the square spacer 3 is matched with a main body support 1 by a fastening pin 2 connected with a pattern 7 .

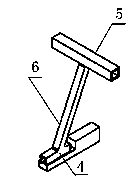

[0015] Such as figure 2 As shown: the main body bracket 1 is assembled from a base 4 of the same shape matched with the lower end of the square spacer 3 , a square top 5 on the upper part, and a rod 6 connecting the two.

[0016] The square pads are 3 cuboids.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com