High-salt diluted-state black soybean sauce and preparation method thereof

A high-salt dilute state, black bean technology, applied in the field of condiments, can solve the problem that the functional components anthocyanins cannot be protected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

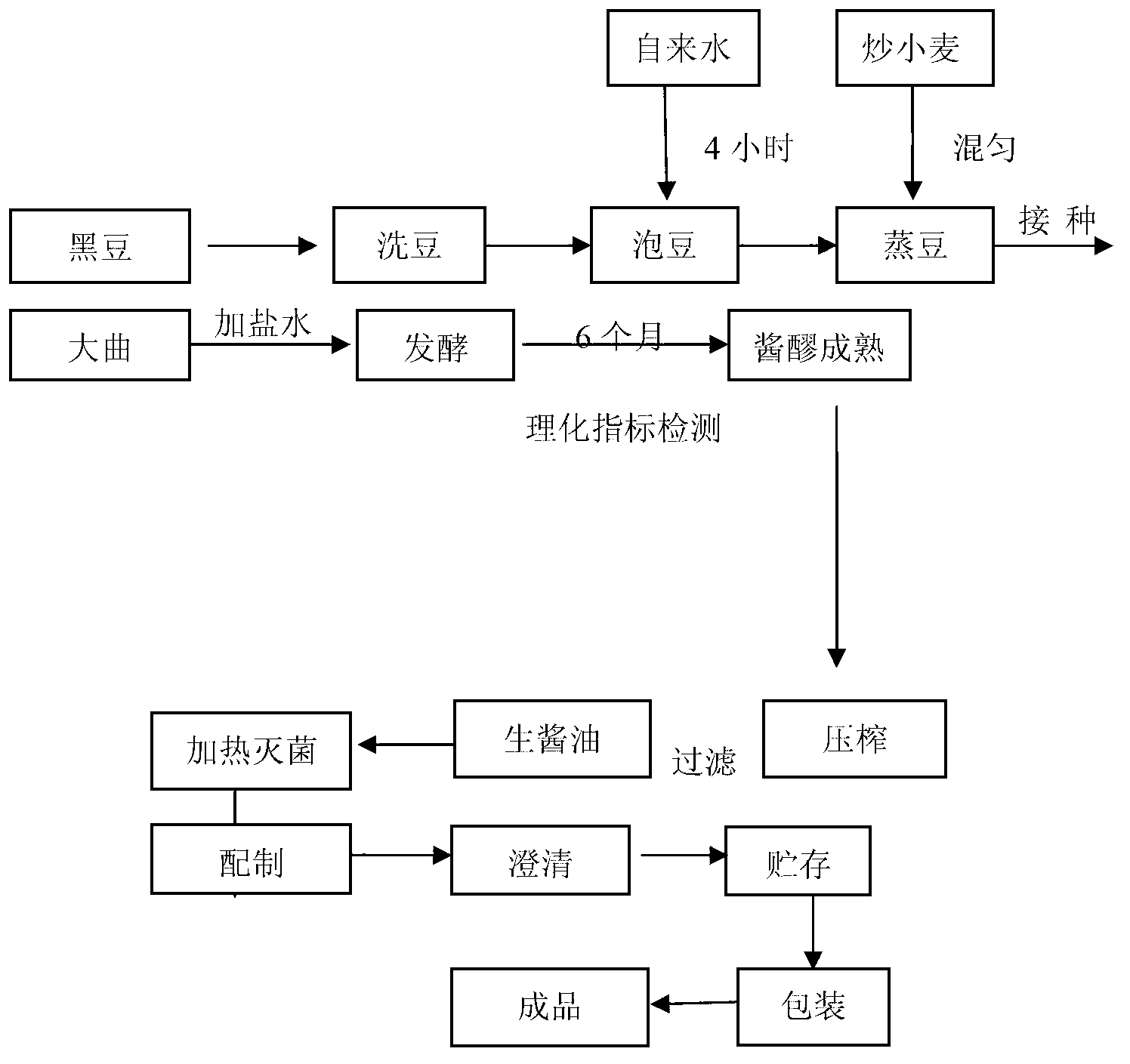

[0034] A preparation method of high-salt dilute black bean soy sauce, the steps are as follows:

[0035] (1) Raw material pretreatment

[0036] After the black beans are selected and cleaned, soak the beans in clear water for 4 hours at a temperature of 30°C. The fried wheat is soaked in boiling water of the same quality for 0.5 hours, and the soaked water soaked with the black beans is retained for recycling. Black beans: fried wheat = 5:5 (mass ratio );

[0037] The black soybeans selected for the raw materials are Heilongjiang Suihua Lvren black soybeans with a protein content between 35% (dry basis) and 45%, and a crude starch content between 28% and 35%. Eligibility criteria for soaking black soybeans: no wrinkles in the appearance of the bean skin, full and shiny after swelling with water, no cracking or peeling of the skin, the soaking rate is greater than 54% to 58%, and the soaking uniformity rate is less than 5%.

[0038] (2) Steamed beans

[0039] The black beans soaked in ...

Embodiment 2

[0051] A method for preparing high-salt dilute black soybean soy sauce, the steps are as follows: (for items not detailed in this example, refer to Example 1, such as seed koji preparation, brine configuration, etc.)

[0052] (1) Raw material ratio and pretreatment

[0053] Black beans: Stir-fried wheat = 5:5 (quality ratio). Black beans are selected. After washing the beans, soak in clean water for 4 hours. The quality of the soaking is through the appearance of the black soybean skin without wrinkles. The beans fully absorb water and expand, full and shiny, without skin cracking. For peeling phenomenon, you can easily pinch it in with your nails. Soak the fried wheat with boiling water of the same quality for 0.5 hours.

[0054] (2) Steamed beans

[0055] The black beans soaked in step (1) are steamed at 121°C, pressure 0.1MPa, and steamed for 20 minutes to ensure that the beans are cooked. After cooking, the digestibility index is tested according to the national standard (STB 1031...

Embodiment 1)

[0056] (3) Making Daqu

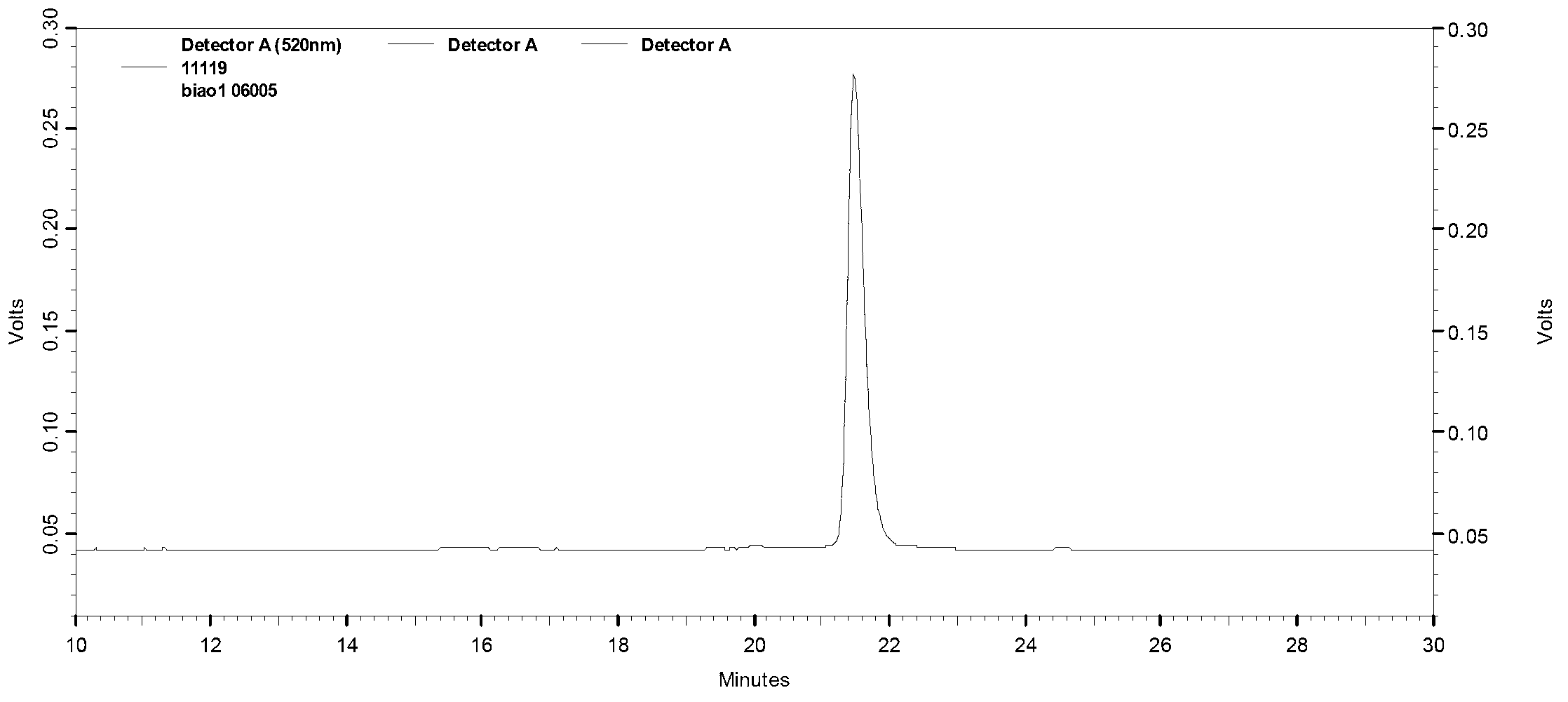

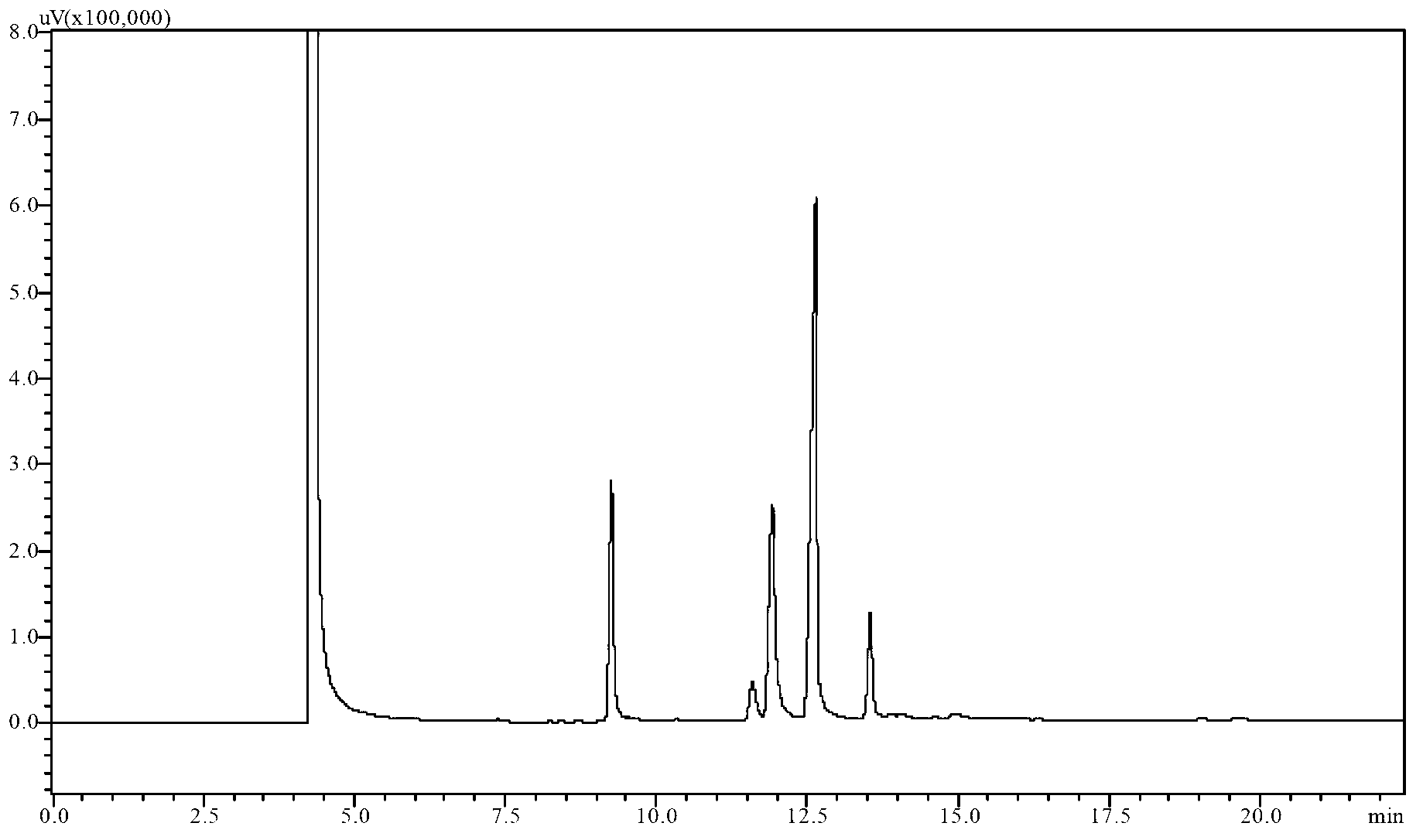

[0057] The steamed black beans are fully mixed with the moisturized fried wheat while the heat is hot, mix the ingredients, wait until the temperature drops below 35°C, insert 0.3% (weight ratio) seed koji, mix well, and ventilate for 36 hours. Collection. Determine the final koji making time by comparing the appearance state of Daqu with protease activity and glucoamylase activity (see attached Pic 4-1 , Attached Figure 4-2 ), that is, the music making ends at the highest point (36 hours in this example).

[0058] (4) Fermentation

[0059] Stir in 18-20°Bé brine with a temperature of 4°C. In order to ensure the full use of anthocyanins and prevent the cooking from being damaged, the brine added here is made up of the water left over from soaking beans, which is combined with Daqu According to the volume ratio of 1.1:1, start fermentation at 15℃, raise one degree a day, stir once every two days, wait until the temperature rises to 30℃, and keep the produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com