Processing method comprehensively utilizing plant oil cake

A processing method and technology for oil cakes are applied in the field of comprehensive utilization and processing of vegetable oil cakes, which can solve the problem that toxic components cannot be completely eliminated, and achieve the effects of promoting animal appetite, increasing coat color brightness, and improving nutrient utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

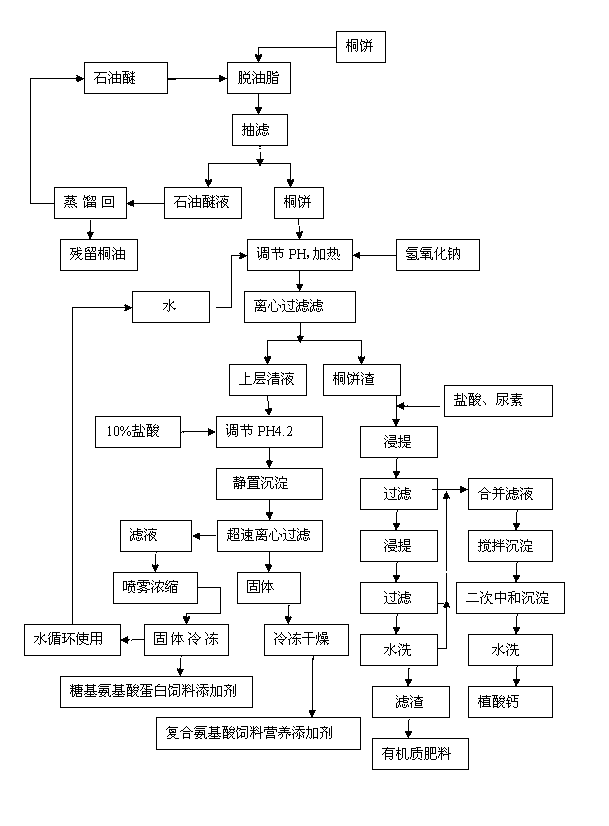

Image

Examples

Embodiment 1

[0032] Weigh 143g of shelled tung kernels and pulverize them, use a Soxhlet extractor to extract 60min at 60°C with 750ml of petroleum ether, take the extract, recover the solvent to obtain 85.9 grams of clear and transparent brown-yellow tung oil, with an oil yield of 60.07%; tung kernel powder 57.1 grams, the cake yield is 39.93%; take 50 grams of Tongren powder, 600 grams of tap water, the solid-to-liquid ratio is 1:12, adjust the pH to 10, the extraction time is 100 minutes, and the extraction temperature is 45°C. Vacuum filtration, the filter residue was washed twice with 50 ml of tap water, and 21 grams of the filter residue was obtained, which was used to extract calcium phytate to prepare organic compound fertilizer; the filtrate was adjusted to PH4.3, and left to stand for 3 hours, and the supernatant was separated, and the lower layer was taken under the condition of 3000r / min Centrifuge for 10 minutes, freeze-dry to obtain 15.8 grams of compound amino acid feed nutri...

Embodiment 2

[0035] Weigh 100g of tung kernels containing husks and pulverize them, use a Soxhlet extractor to extract 650ml of petroleum ether at 60°C for 60min, take the extract, recover the solvent to obtain 9.1g of clear and transparent brown yellow tung oil, obtain 90.9g of tung cake residue, and take 910g of tap water gram, adjust the pH to 10, the extraction time is 100min, and the extraction temperature is 45°C. Vacuum filtration, the filter residue was washed twice with 100 ml of tap water, and 48.7 grams of the filter residue was used to extract calcium phytate to prepare organic compound fertilizer; the filtrate was adjusted to pH 4.3, and left to stand for 3 hours. It was centrifuged for 10 minutes, freeze-dried to obtain 13.1 grams of compound amino acid feed nutritional additives, and the filtrate was sprayed, concentrated and freeze-dried to obtain 27.0 grams of glycosyl amino acid protein feed additives.

Embodiment 3

[0037] Take 50 grams of degreased and deoiled tung cake powder, 600 grams of tap water, solid-to-liquid ratio of 1:12, adjust the pH to 2.-3, heat at 90°C for 6 hours, vacuum filter, wash 2 times with 50 ml of filter residue, and prepare organic matter with 22.5 grams of filter residue Compound fertilizer; add 5 grams of activated carbon to the filtrate, stir and decolorize at 70°C for 30 minutes, vacuum filter, wash twice with a small amount of water, and use the activated carbon filter residue to prepare compound fertilizer; adjust the filtrate to PH4.2-4.3, let it stand for 4 hours, filter, and freeze-dry to obtain 10.7 grams of compound amino acid feed nutritional additives, the filtrate was sprayed and concentrated, and freeze-dried to obtain 13.9 glycosyl amino acid protein feed additives.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com