Light-cured colorized composition for color filter

A technology of coloring composition and color filter, which is applied in the direction of photosensitive materials, optics, and optomechanical equipment used in optomechanical equipment, and can solve problems such as uneven thickness, erosion, and white light on displays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

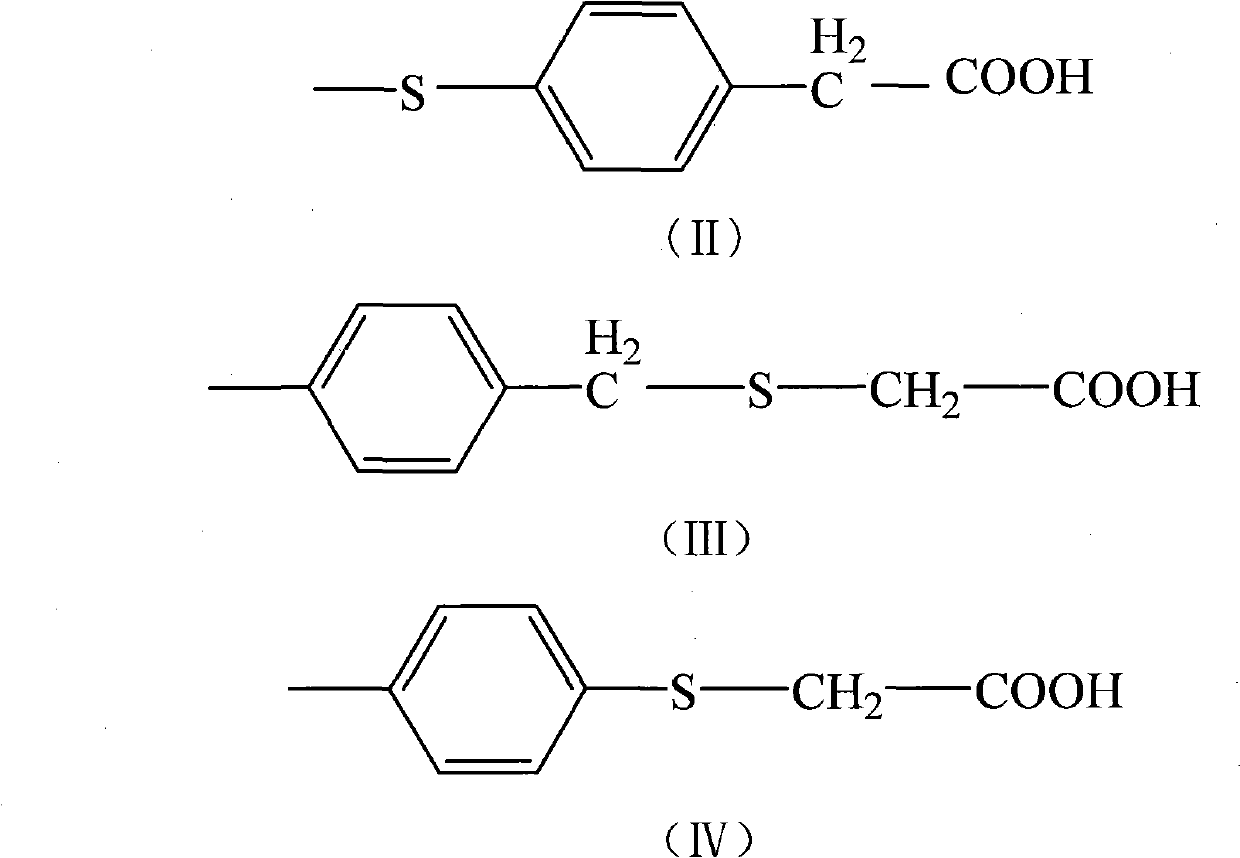

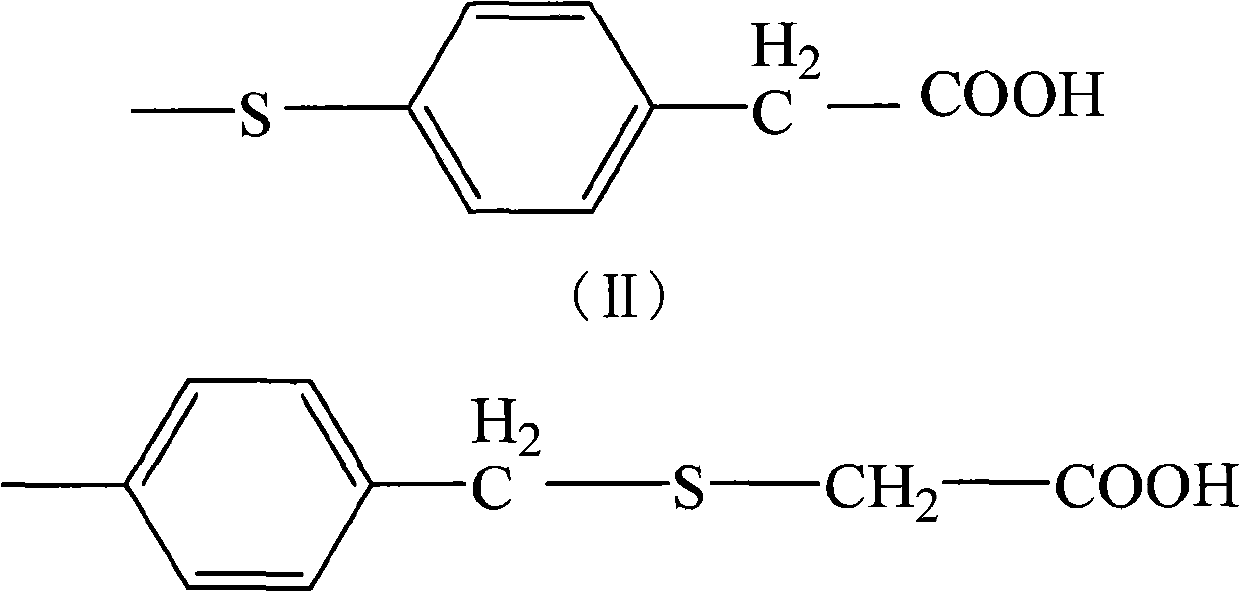

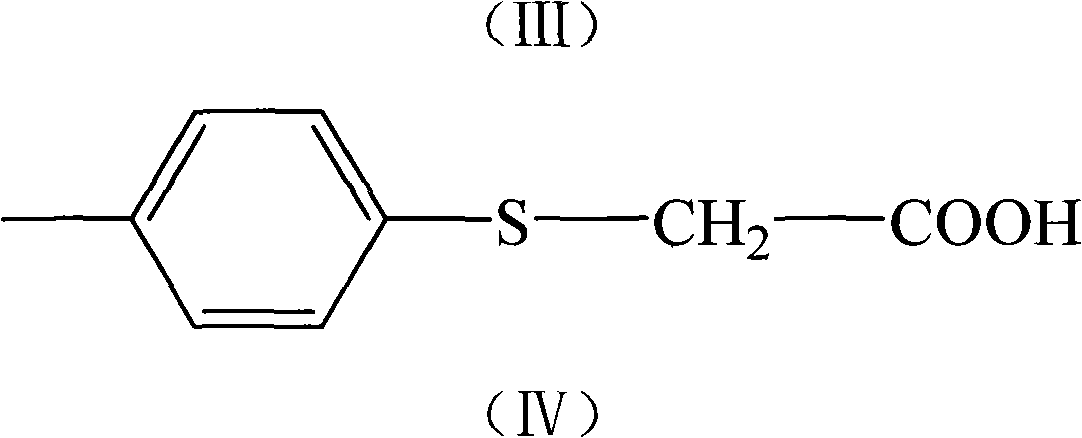

Image

Examples

Embodiment 1

[0084] The photocurable coloring composition can be prepared by mixing and stirring the following components for 2 hours:

[0085] Hydroxyethyl acrylate / glycidyl methacrylate and unsaturated monobasic acid adduct / p-carboxymethylthiostyrene copolymer ------8 parts

[0086] (copolymerization ratio is 25:45:30, weight average molecular weight is 12000)

[0087] Dipentaerythritol hexaacrylate ------8 parts

[0088] IRGACURE 369 ------0.6 parts

[0089] IRGACURE OXE01 ------0.5 parts

[0090] Isopropylthioxanthone ------0.6 parts

[0091] Cyclohexanone ------38 parts

[0092] The following pigment dispersion* ------44 parts

[0093] BYK UV3500 ------0.3 parts

[0094] Pigment Dispersion*

[0095] The following components were ground with a sand mill for 6 hours to obtain a pigment dispersion.

[0096] Pigment red P.R254 ------30 parts

[0097] Styrene / hydroxyethyl acrylate / methacrylic acid copolymer------7 parts

[0098] Solsperse 24000 ------15 parts

[0099] Cyclohexan...

Embodiment 2

[0101] "Hydroxyethyl acrylate / glycidyl methacrylate and unsaturated monobasic acid adduct / p-carboxymethylthio styrene copolymer" in Example 1 is replaced by the following copolymer, and all the other are the same as (Example 1):

[0102] Styrene / glycidyl methacrylate and unsaturated monobasic acid adduct / carboxymethyl allyl sulfide copolymer (copolymerization ratio 30:40:30, weight average molecular weight 12000).

Embodiment 3

[0104] "Styrene / hydroxyethyl acrylate / methacrylic acid copolymer" in the pigment dispersion liquid in embodiment 1 is replaced with following resin, and all the other are the same as embodiment 1:

[0105] Hydroxyethyl acrylate / p-carboxymethylthiostyrene / glycidyl methacrylate and unsaturated monobasic acid adduct (copolymerization ratio 25:45:30, weight average molecular weight 12000).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com