Upper-blocking and lower-draining construction method for undersea tunnel fault fracture zone

A subsea tunnel and construction method technology, which is applied to tunnels, tunnel linings, underground chambers, etc., can solve the problem of not being able to meet the requirements of reinforcement strength and limited drainage of tunnels, not only being able to ensure the safety of construction excavation, and dealing with fault fracture zone for a long period, etc. problems, achieve the effect of reducing blindness, reducing the number of drilling and grouting, and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further explained below in conjunction with the accompanying drawings. It should be noted that the purpose of disclosing the present invention is to protect the construction method within the concept of the present invention and the relevant technical standards and parameters proposed. The excavation and drainage of the lower half section and the development of rock-soil zones through fault fracture zones or fissures are all within the protection scope of the present invention.

[0034] In order to make the above objects, features, advantages and related technical parameters of the present invention more obvious and understandable, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

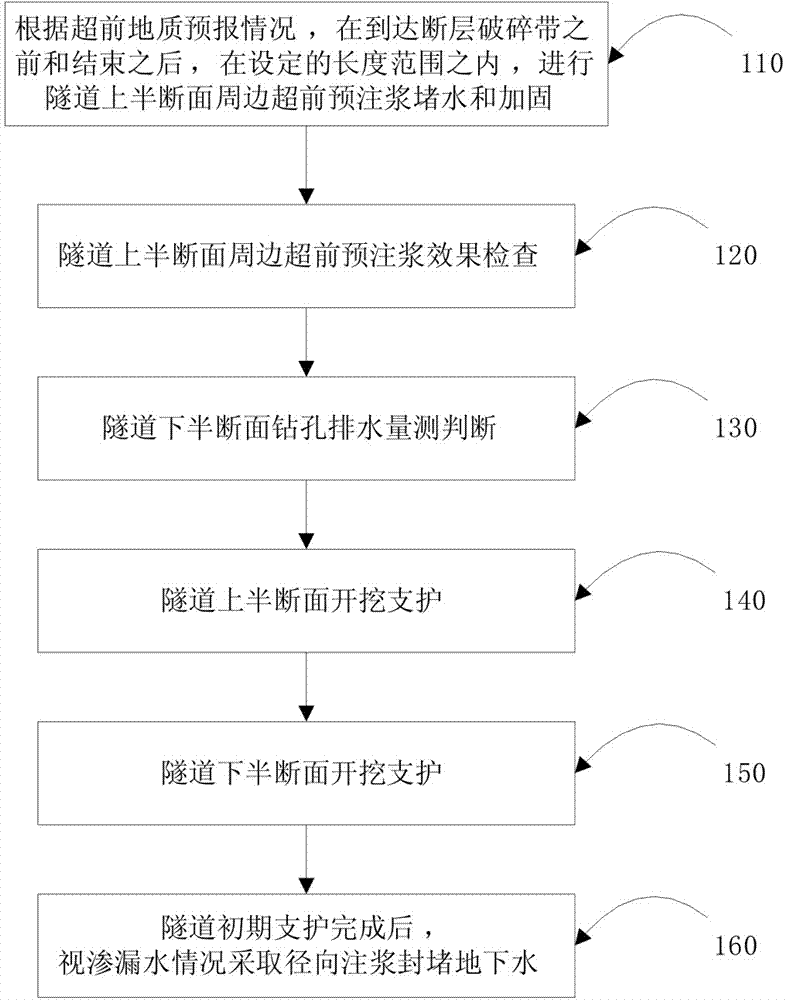

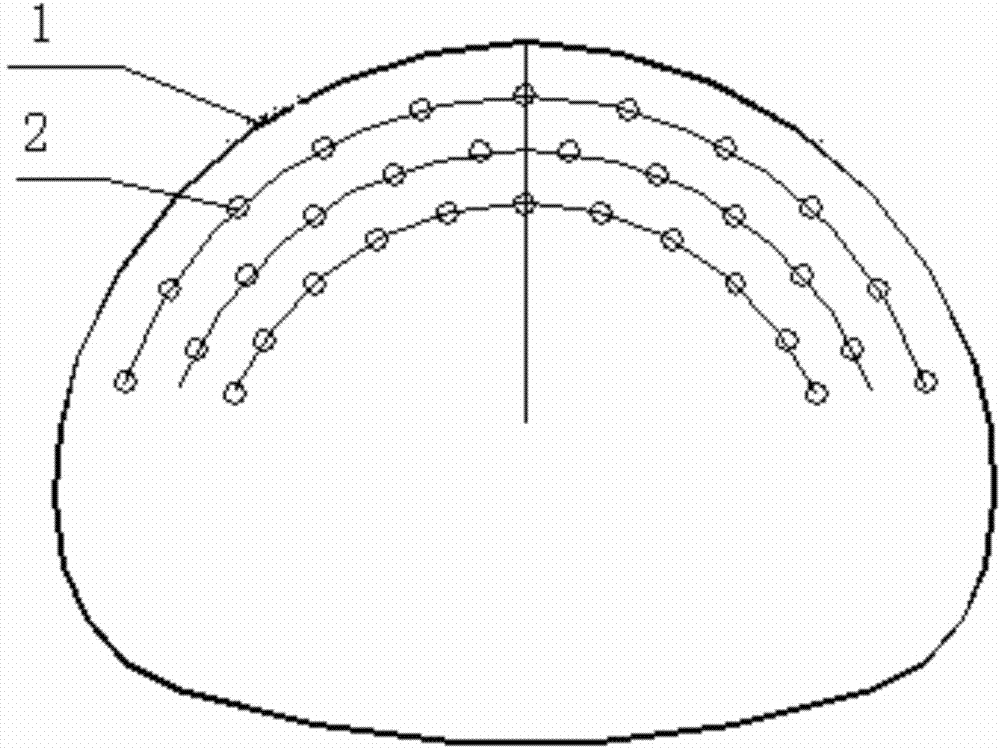

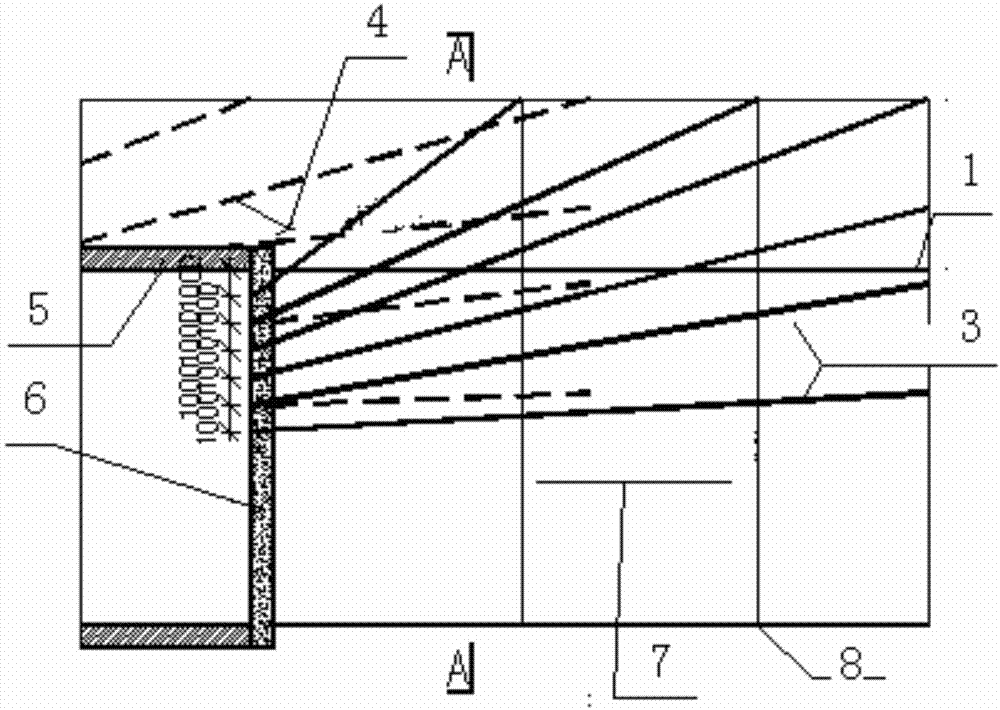

[0035] like figure 1 As shown, a construction method for subsea tunnel fault fracture zone with upper blockage and lower row, adopts two major co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com