All-in-one machine thermal master base paper

A thermal plate paper, all-in-one technology, used in paper, papermaking, special paper, etc., can solve the problems of low resolution, insufficient chromaticity, low printing durability, etc., to achieve high resolution, uniform chromaticity, Good ink permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

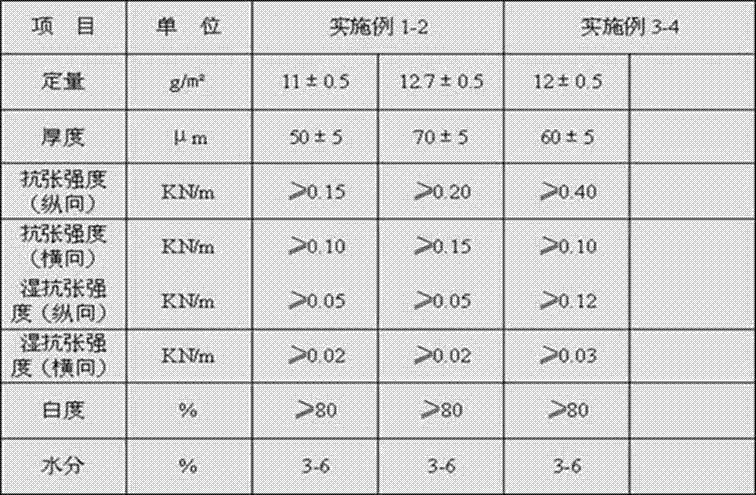

Examples

Embodiment 1

[0031] An all-in-one heat-sensitive base paper, which is prepared by the following steps:

[0032] 1) The raw materials LPET / PET low-melting point two-component polyester ultra-short fiber, PET polyester ultra-short fiber, viscose fiber, and northern wood pulp are mixed and beaten according to a certain ratio;

[0033] 2) Add PAM solution with a viscosity of 30-35 seconds, mix and dissolve;

[0034] 3) Sizing and forming in the wire section of the side wave special fourdrinier paper machine;

[0035] 4) After being dried on the surface of the first dryer, it is sent to the surface of the second dryer for bonding and curing;

[0036] 5) After the paper is rolled and cut, it is coated with a strengthening agent, and finally rewinded to produce an all-in-one heat-sensitive base paper;

[0037] The weight percent of each raw material in step 1) is: LPET / PET low-melting point two-component polyester ultra-short fiber: 13%; PET polyester ultra-short fiber: 35%; viscose fiber: 22%;...

Embodiment 2

[0042] An all-in-one heat-sensitive base paper, which is prepared by the following steps:

[0043] 1) The raw materials LPET / PET low-melting point two-component polyester ultra-short fiber, PET polyester ultra-short fiber, viscose fiber, and northern wood pulp are mixed and beaten according to a certain ratio;

[0044] 2) Add PAM solution with a viscosity of 30-35 seconds, mix and dissolve;

[0045] 3) Sizing and forming in the wire section of the side wave special fourdrinier paper machine;

[0046] 4) After being dried on the surface of the first dryer, it is sent to the surface of the second dryer for bonding and curing;

[0047] 5) After the paper is rolled and cut, it is coated with a strengthening agent, and finally rewinded to produce an all-in-one heat-sensitive base paper;

[0048] The weight percentage of each raw material in the step 1) is: LPET / PET low-melting point two-component polyester ultra-short fiber: 18%; PET polyester ultra-short fiber: 35%; viscose fibe...

Embodiment 3

[0053] An all-in-one heat-sensitive base paper, which is prepared by the following steps:

[0054] 1) The raw materials LPET / PET low-melting point two-component polyester ultra-short fiber, PET polyester ultra-short fiber, and sisal pulp fiber are mixed and beaten according to a certain ratio;

[0055] 2) Add PAM solution with a viscosity of 30-35 seconds, mix and dissolve;

[0056] 3) Sizing and forming on the wire part of the rotary paper machine or inclined screen paper machine;

[0057] 4) After being dried on the surface of the first dryer, it is sent to the surface of the second dryer for bonding and curing;

[0058] 5) After the paper is rolled and cut, it is coated with a strengthening agent, and finally rewinded to produce an all-in-one heat-sensitive base paper;

[0059] The weight percent of each raw material in step 1) is: LPET / PET low-melting point two-component polyester ultra-short fiber: 14%; PET polyester ultra-short fiber: 37%; Sisal pulp fiber: 49%;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com