Method for ramie wool type spinning

A processing method, ramie technology, applied in the textile field, can solve problems such as low efficiency and spinning processing, and achieve the effects of improving quality and efficiency, improving yarn quality, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Ramie spinning is carried out according to the processing flow of wool spinning (untwisted roving), dry hemp → soft hemp (CZ141 type ramie soft hemp machine) → opening (improved FZ002 type ramie opening machine) → combing hemp (improved CZ191 type ramie Carding machine) → needle carding strip (B302 needle carding machine → B304 needle carding machine) → combing (B311D carding machine) → pre-spinning (B423 needle carding machine → B432 needle carding machine → B442 needle carding machine → FB441 twistless roving frame) → post-spinning (FB504 spinning frame).

[0035] The present embodiment adopts the fine-dried ramie hemp produced in Hunan, and its properties are as shown in Table 1.

[0036] Table 1: Performance indicators of lean hemp

[0037]

[0038] The process of opening and combing the hemp of the present invention is adopted for the above-mentioned refined hemp raw material.

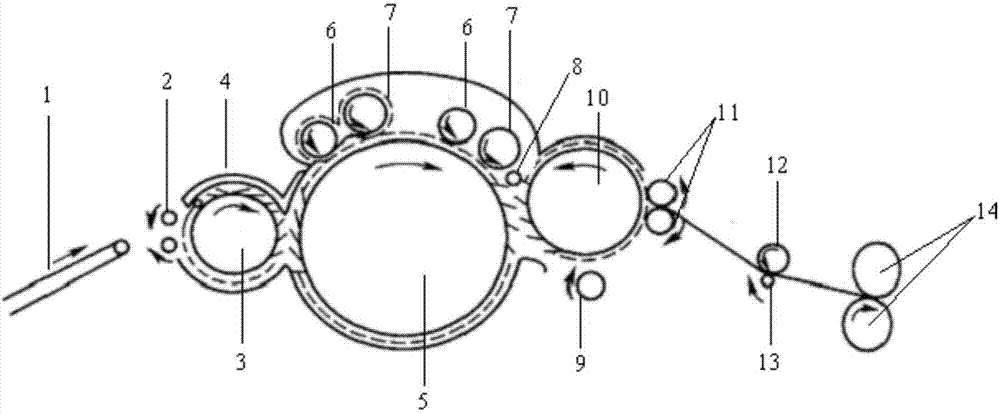

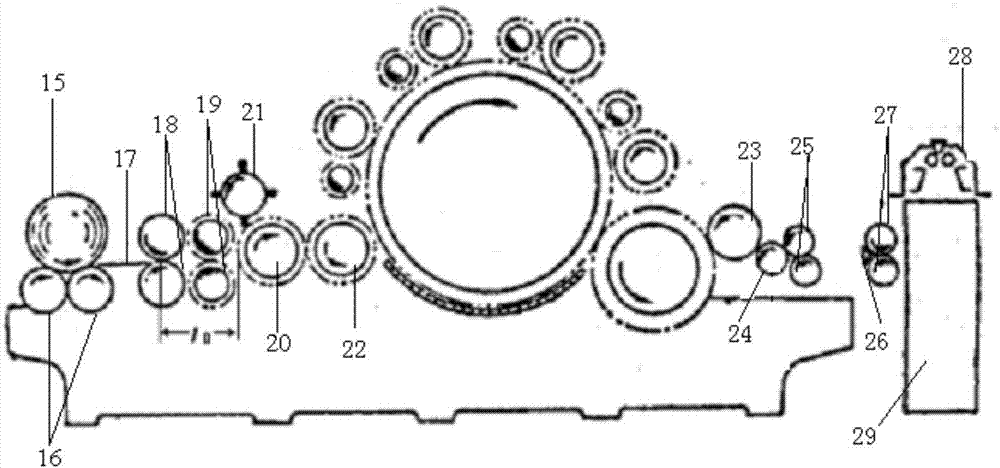

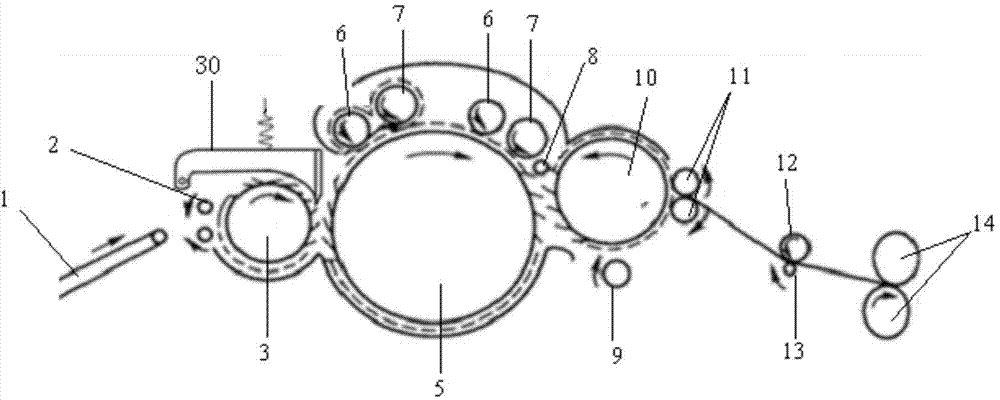

[0039] image 3 It is a structural schematic diagram of the improved opening devi...

Embodiment 2

[0052] The carded sliver of the present invention of Example 1 is directly used for subsequent processing on the wool spinning equipment (twisted roving) flow process. The processing flow is B302 carding machine→B304 carding machine→B311D combing machine→B423 carding machine→B432 carding machine→B442 carding machine→B465A roving frame→EJ519 spinning frame.

[0053] The front gauges of B302 and B304 carding machines are 35mm and 40mm respectively; The front gauge is 25mm, the roving twist coefficient is 21, the drafting back gauge of the EJ519 spinning frame is 110mm, and the depth of the chute is 1.5mm.

[0054] Others are all the same as in Example 1.

[0055] Wool type ramie yarn of the present invention and the ramie yarn performance contrast of existing conventional ramie yarn (combed) are as shown in table 5.

[0056] Table 5 Ramie yarn performance comparison (27.8tex)

[0057]

[0058] The results show that after the ramie fiber is processed into wool-like length, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com