Preparation method of overlong copper nanowire and conductive copper nanowire film

A copper nanowire, ultra-long technology, applied in the field of materials, can solve problems such as difficult dispersion, difficult application, harsh reaction conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

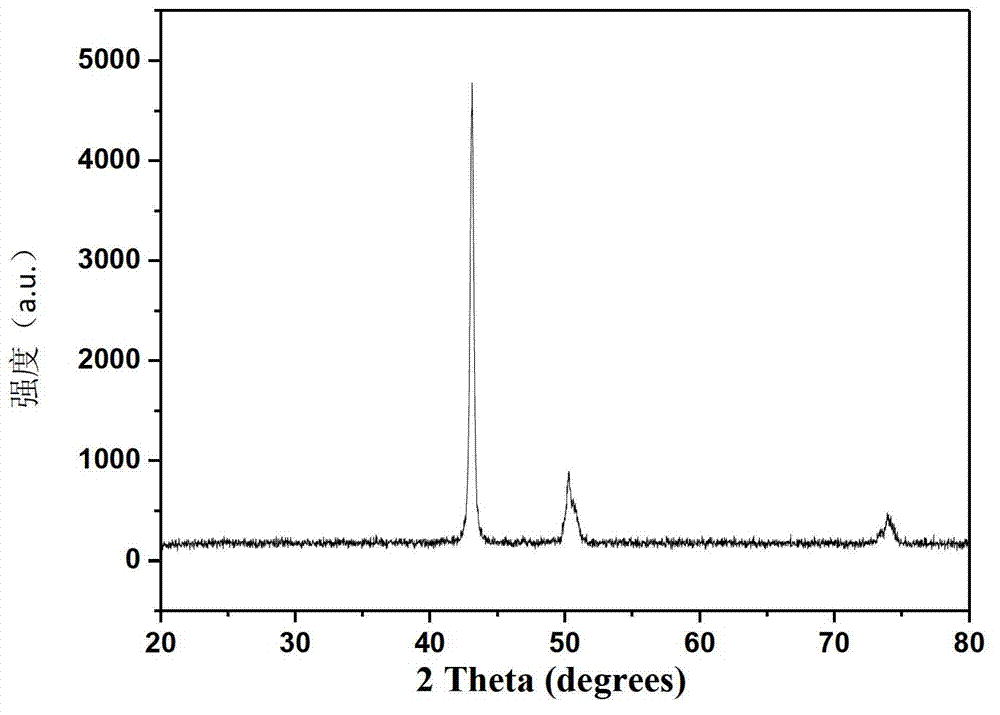

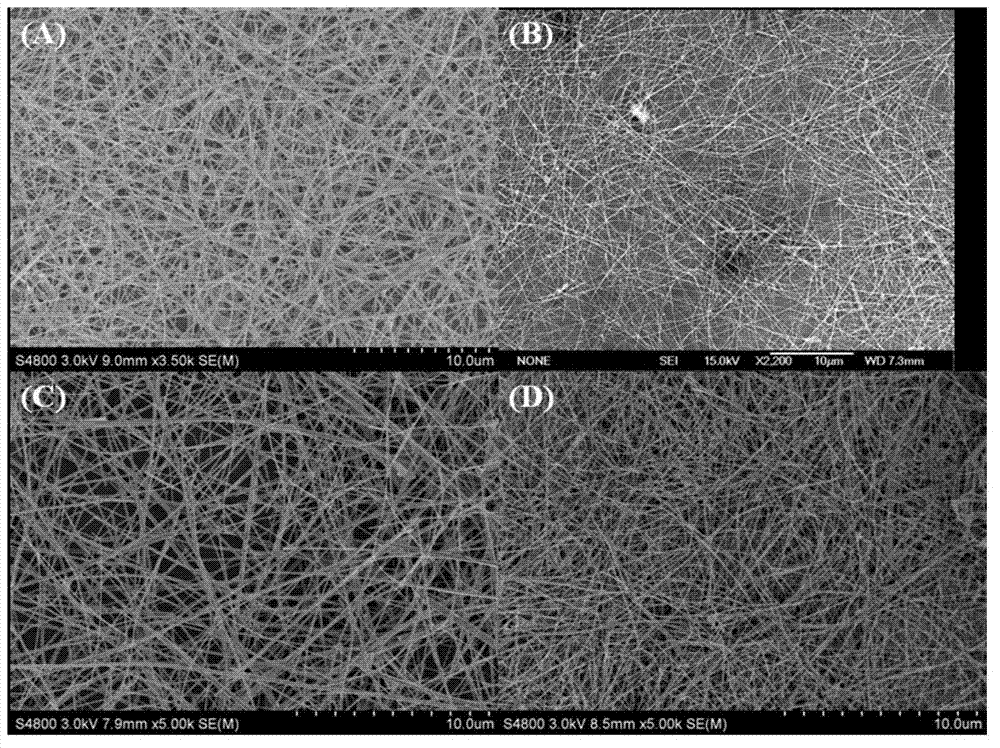

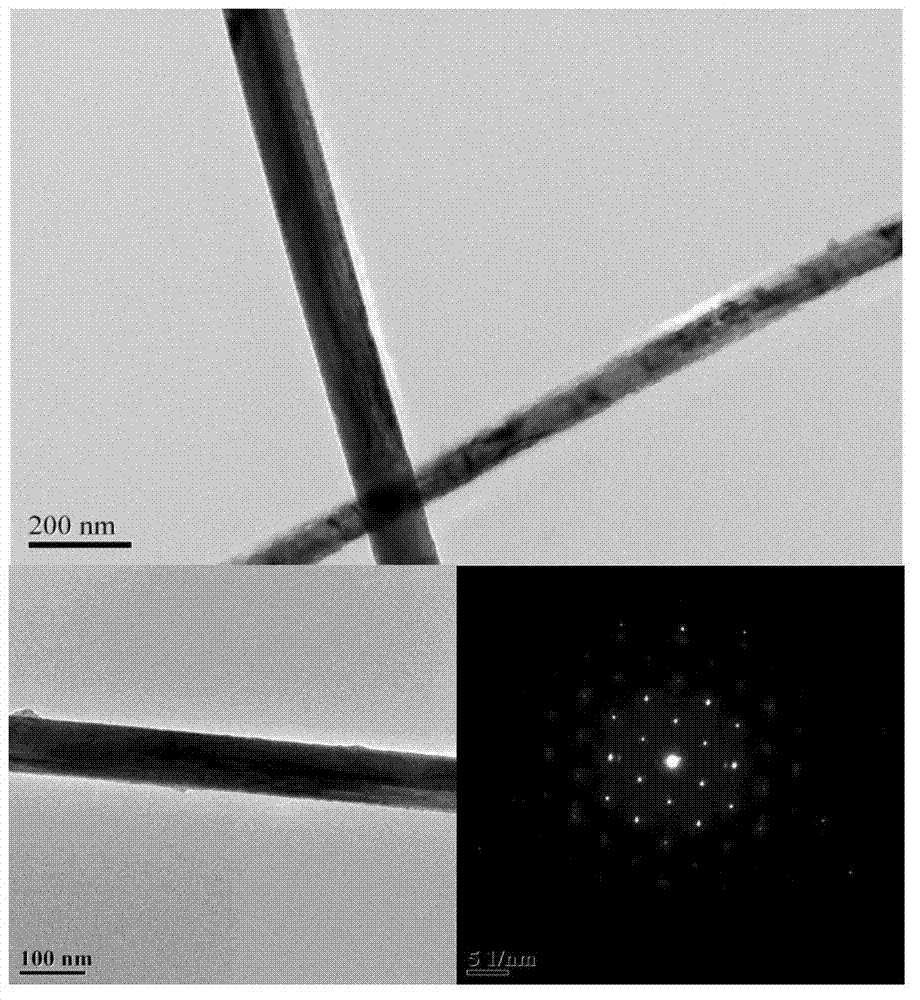

Embodiment 1

[0022] Dissolve 0.5g of hexadecyltrimethylammonium bromide in 8.0g of hexadecylamine completely at 180°C, then add 0.2g of copper acetylacetonate as a copper source; use a Pt-coated silicon wafer as a catalyst, at 140°C The reaction was carried out at high temperature for 10 h, and after cooling to room temperature, the obtained sample was taken out and washed several times with toluene. The obtained brown-red solid was vacuum-dried at 80° C. for 2 hours.

Embodiment 2

[0024] Dissolve 0.5g of hexadecyltrimethylammonium bromide in 8.0g of hexadecylamine completely at 180°C, then add 0.2g of copper acetylacetonate as a copper source, and use a Pt-coated silicon wafer as a catalyst at 150°C The reaction was carried out at high temperature for 10 h, and after cooling to room temperature, the obtained sample was taken out and washed several times with toluene. The obtained brown-red solid was vacuum-dried at 80° C. for 2 hours.

Embodiment 3

[0026] Dissolve 0.5g of hexadecyltrimethylammonium bromide in 8.0g of hexadecylamine completely at 180°C, then add 0.2g of copper acetylacetonate as a copper source, and use a Pt-coated silicon wafer as a catalyst at 160°C Reaction at high temperature for 10h, after cooling to room temperature, the resulting sample was taken out and washed several times with toluene. The obtained brown-red solid was vacuum-dried at 80° C. for 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com