Preparation method for soft powder metal composite coiled material

A powder metal and metal composite technology, which is applied in building insulation materials, building components, buildings, etc., can solve the problems of inconsistent performance, high price, and restrictions on wide-scale promotion and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

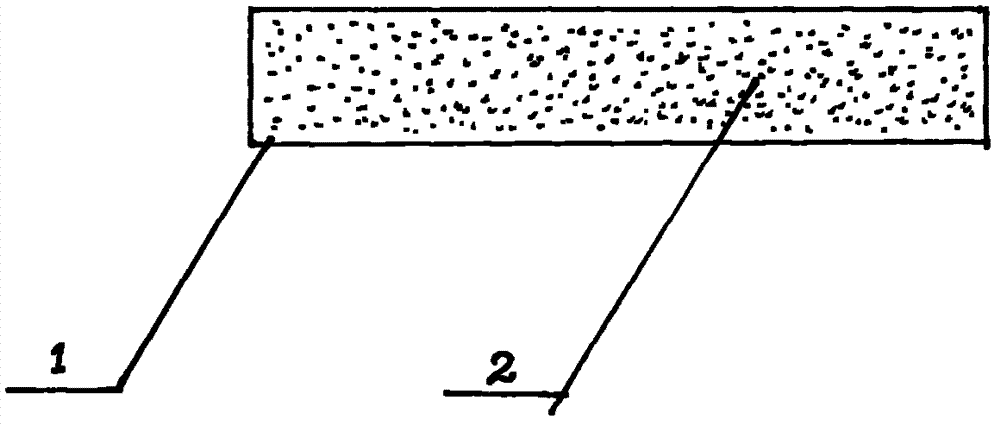

Image

Examples

Embodiment 1

[0013] Embodiment 1 In radiation workplaces, high lead-containing soft elastic materials can be used to make various anti-radiation clothing, so that people can work flexibly while being better protected.

Embodiment 2

[0014] Example 2 In high-standard places that require anti-static, soft elastic materials with high content of copper powder can be used to make special anti-static covers, anti-static clothing, anti-static boards and other products.

Embodiment 3

[0015] Example 3 In the field of building sound insulation, soft elastic materials made of high-density metal powders such as iron and steel are made into coils of different thicknesses, which can play a good role in sound insulation, and can be cut with a knife because of its softness and elasticity. , very convenient to use.

[0016] In summary, the application of soft powder metal composites will have a very broad prospect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com