Waterproof permeable material having antibacterial function, and its preparation method

A waterproof, breathable and functional technology, applied in the fields of clothing and medical supplies, can solve the problems of large amount of nano-antibacterial agent, high cost of nano-silver, hidden safety hazards, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

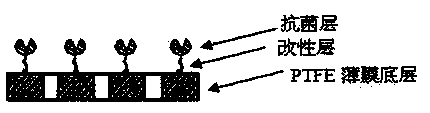

[0037]The invention is a waterproof and air-permeable material with antibacterial function. The material uses a waterproof and air-permeable PTFE film as a base material and lysozyme as an antibacterial agent. The dopamine method is used to modify the surface of one side of the PTFE film and introduce active groups, and then react with lysozyme to form an antibacterial layer on the surface of the film. The structure diagram of the antibacterial material is as follows: Image 6 shown.

[0038] A preparation method of a waterproof breathable material with antibacterial function, the specific steps are as follows:

[0039] Step 1: In the dopamine solution with a pH of 8.5 and a concentration of 2 mg / ml, add a waterproof and breathable PTFE film with a film thickness of 80 μm and a pore size of about 0.1 μm. The scanning electron microscope picture is as follows figure 1 As shown, take it out after reacting at room temperature for 8 hours, wash it with deionized water, and obtain...

Embodiment 2

[0047] A preparation method of a waterproof breathable material with antibacterial function, the specific steps are as follows:

[0048] Step 1. Add a waterproof and breathable PTFE film to the dopamine solution with a pH of 5.0 and a concentration of 20 mg / ml. The film thickness is 20 μm and the pore size is about 0.5 μm. After reacting at room temperature for 24 hours, take it out and wash it with deionized water. , to obtain a PTFE film after surface modification on one side;

[0049] Step 2: Put the PTFE film obtained in step 1 after the unilateral surface modification into a 0.02M carbonate buffer solution of lysozyme with a pH of 10 and a lysozyme concentration of 100 mg / ml, and react for 12 hours to obtain PTFE antibacterial film.

[0050] The antibacterial rate of the prepared antibacterial material to streptococcus reaches 80%.

Embodiment 3

[0052] A preparation method of a waterproof breathable material with antibacterial function, the specific steps are as follows:

[0053] Step 1. Add a waterproof and breathable PTFE film to the dopamine solution with a pH of 10 and a concentration of 0.001 mg / ml. The film thickness is 40 μm and the pore size is about 0.3 μm. After reacting at room temperature for 2 hours, take it out and wash it with deionized water. Clean, obtain the PTFE film after one side surface modification;

[0054] Step 2: Put the PTFE film obtained in step 1 after the unilateral surface modification into a 0.05M acetate buffer solution of lysozyme with a pH of 5 and a lysozyme concentration of 0.001 mg / ml, and react for 2 hours to obtain PTFE Antibacterial film.

[0055] The antibacterial rate of the prepared antibacterial material against diplococci reaches 60%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com