Nano waterborne ink binder and preparation method thereof

A technology of water-based ink and linking material, which is applied in ink, household utensils, applications, etc., can solve the problems of poor drying performance of water-based ink linking material and inability to use high-speed printing, etc., to achieve easy operation, improve poor drying performance, and high solid content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

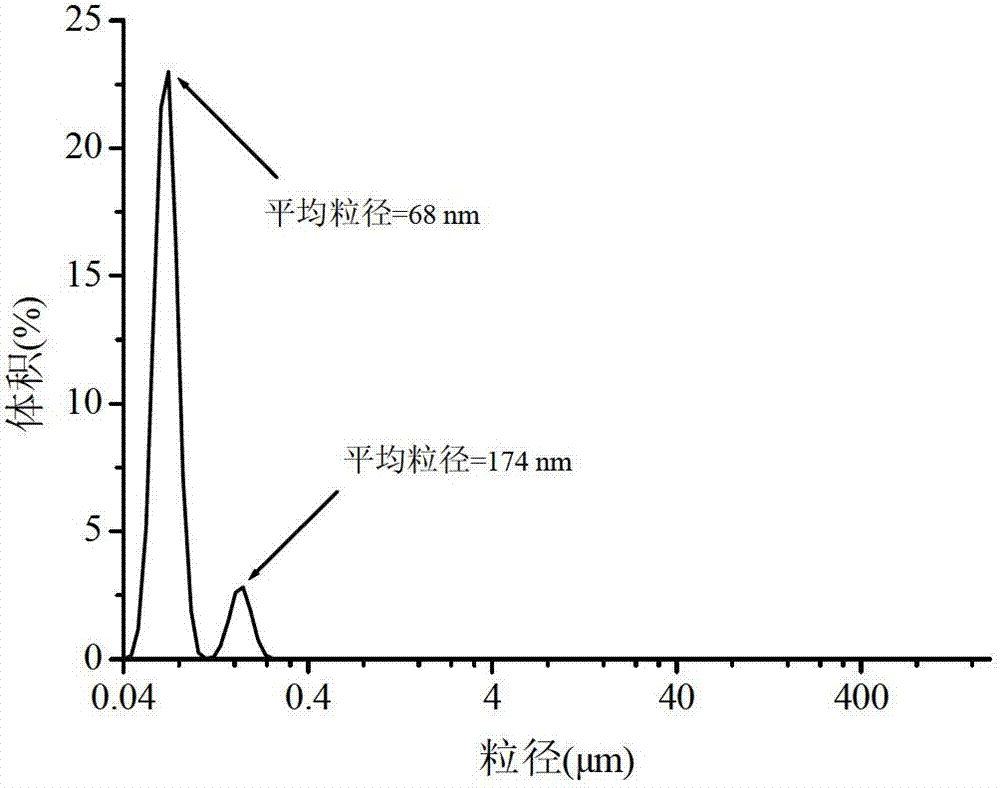

Image

Examples

preparation example Construction

[0031] A kind of preparation method of above-mentioned nano water-based ink linking material: specifically comprise the steps:

[0032] a. Heat isophorone diisocyanate and polypropylene glycol to 80~90°C and stir for 2~3 hours, add catalyst dibutyltin dilaurate and continue to stir for 20min~50min to react; during the reaction, detect the remaining amount of isocyanate group, When the detected remaining amount reaches the theoretical value, the temperature of the reaction solution is lowered;

[0033] The detection of the remaining amount of isocyanate groups is as follows: using di-n-butylamine titration to detect the isocyanate groups in the reaction solution.

[0034] Described di-n-butylamine titration comprises the following steps:

[0035] A) Prepare di-n-butylamine solution, add the sample taken from the reaction solution into anhydrous toluene; then add di-n-butylamine solution and mix well and let it stand for 20~30min;

[0036] B) Add isopropanol and bromocresol gree...

Embodiment 1

[0054] Embodiment 1, a kind of nano water-based ink link material, adopts the raw material of parts by weight in table 1:

[0055] Table 1 Nano water-based ink link material raw material ratio table

[0056]

[0057] Preparation:

[0058] a. Dry PPG-2000 in a drying oven at 120°C and 0.04Mpa vacuum for 1 hour, after the drying is completed. Add IPDI and PPG-2000 into a clean four-neck flask with reflux condenser, thermometer and stirring device, put the flask into a constant temperature water bath at 85°C, stir for 2 hours, add 0.1‰ catalyst, and react for 30 minutes , so that the reaction between IPDI and PPG-2000 is sufficient;

[0059] During the reaction process, a 3g sample was weighed from the reaction solution, placed in a clean Erlenmeyer flask, and the remaining amount of isocyanate group (-NCO) in the reaction solution was detected by di-n-butylamine titration. When the amount of -NCO in the sample reached the theoretical value, the temperature began to drop. ...

Embodiment 2

[0072] Embodiment 2, a kind of nano water-based ink linking material, adopts the raw material of parts by weight in table 1:

[0073] Table 2 Nano water-based ink link material raw material ratio table

[0074]

[0075] Preparation:

[0076] a. Dry PPG-2000 in a drying oven at 120°C and 0.04Mpa vacuum for 1 hour, after the drying is completed. Add IPDI and PPG-2000 into a clean four-neck flask with reflux condenser, thermometer and stirring device, put the flask into a constant temperature water bath at 80°C, stir and react for 2.5 hours, then add 0.26‰ catalyst and react for 20 minutes , so that the reaction between IPDI and PPG-2000 is sufficient;

[0077] During the reaction process, a 3g sample was weighed from the reaction solution, placed in a clean Erlenmeyer flask, and the remaining amount of isocyanate group (-NCO) in the reaction solution was detected by di-n-butylamine titration. When the amount of -NCO in the sample reached the theoretical value, the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com