Novel kitchen garbage fermentation device and usage method

A technology for kitchen waste and fermentation equipment, applied in application, chemical industry, organic fertilizer and other directions, can solve the problems of uneven ventilation of fermentation materials and uneven heating effect of fermentation tanks, so as to reduce the risk of secondary pollution and reduce transportation. Cost and treatment cost, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail in conjunction with the accompanying drawings and specific embodiments of the device.

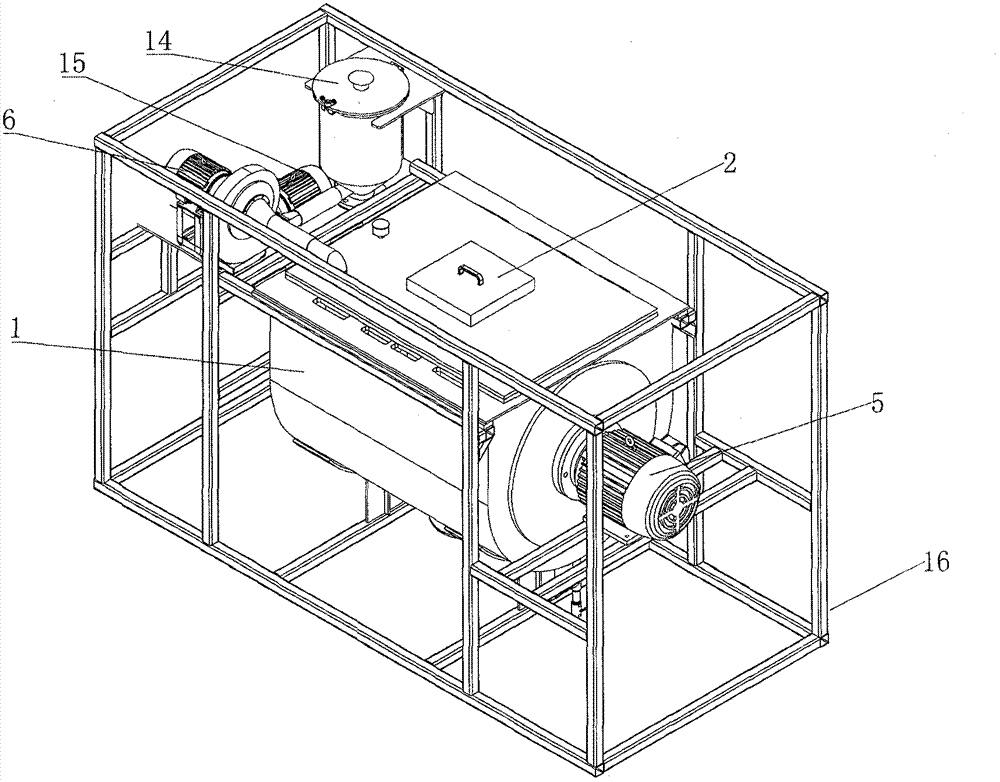

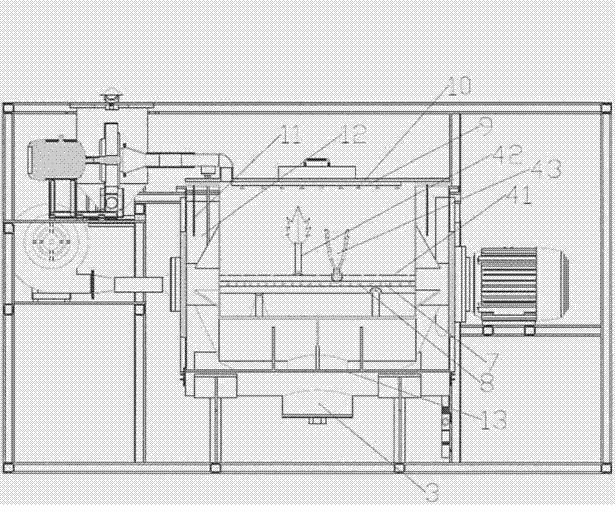

[0020] see Figure 1-Figure 3 , a food waste fermentation equipment comprising: U-shaped fermenter 1, feed port 2, discharge port 3, crushing agitator 4, frequency conversion motor 5, blower 6, ventilation pipe 7, ventilation hole 8, microbial feed pipe 9. Microbial feed nozzle 10, electric heating tube 11, water interlayer 12, protective layer 13, deodorizing tower 14, exhaust fan 15, bracket 16, etc.

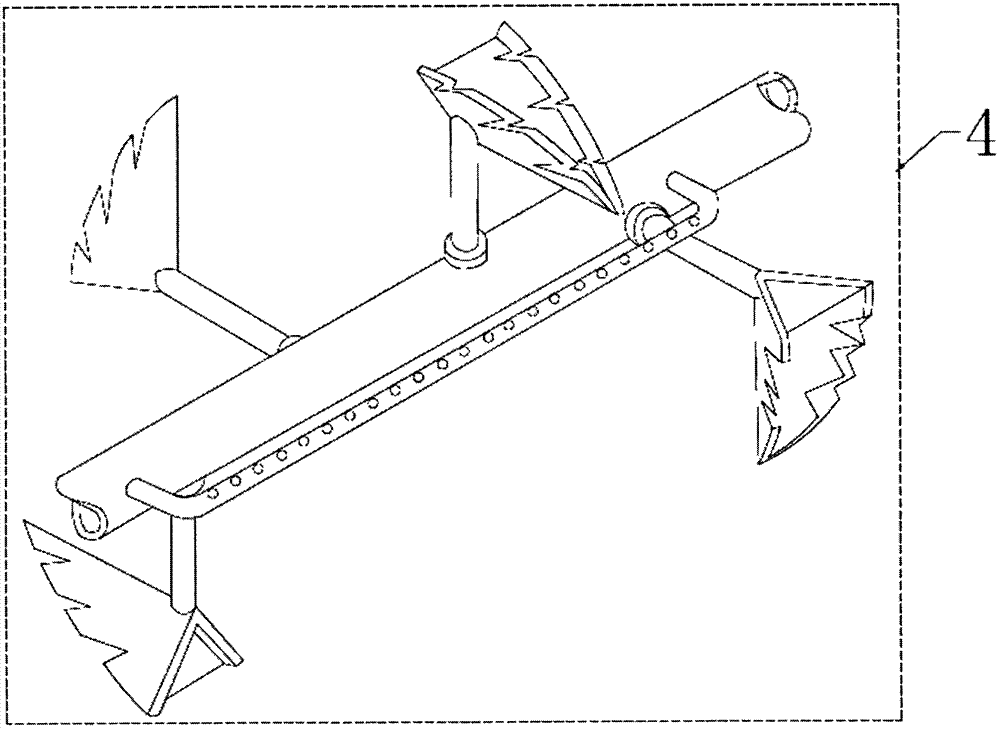

[0021] The U-shaped fermenter 1 is supported by a bracket 16, the top central part is a food waste feeding port 2, and the bottom is provided with a discharge port 3. The crushing agitator 4 is installed at the center of the U-shaped fermenter 1, and is composed of a stirring horizontal shaft 41, a fan blade support 42, and a fan blade 43. The fan blade support is installed on the stirring horizontal shaft at the same distance, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com