Automatic vacuum suction key fixture

A vacuum adsorption and vacuum suction technology, which is applied in the field of mobile phone button production auxiliary equipment, can solve the problems of high labor intensity, low product production capacity, high labor cost, etc., and achieve ideal adsorption effect and strong waste adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

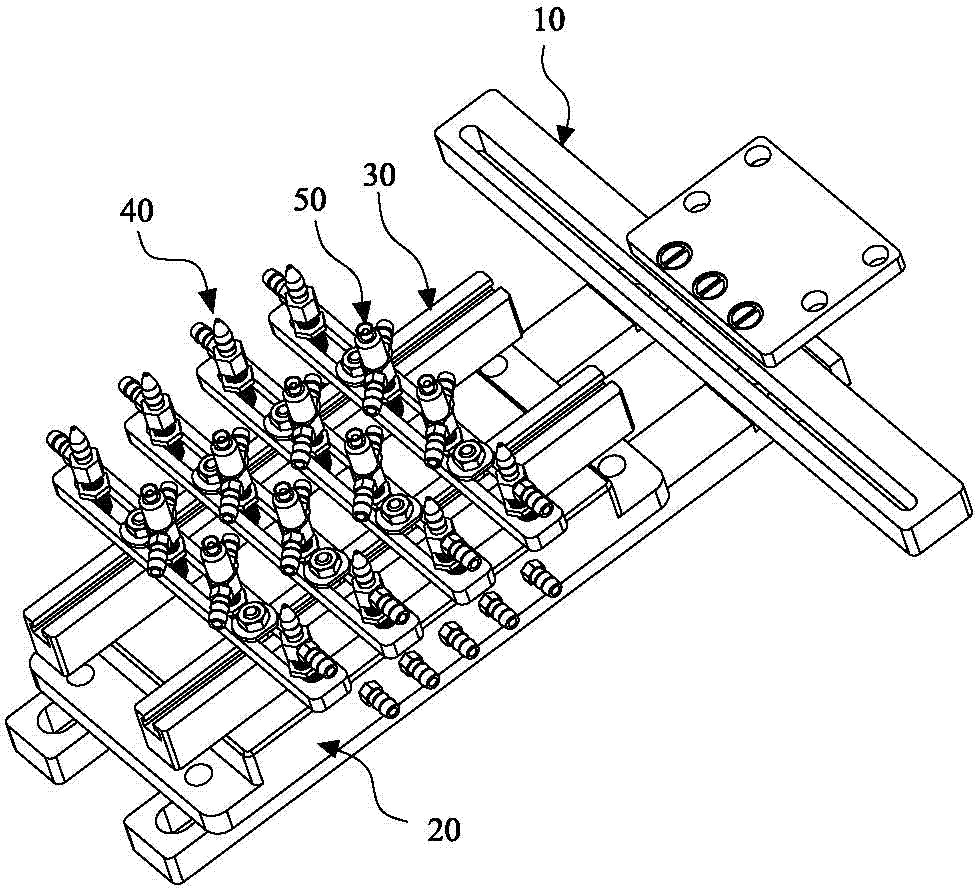

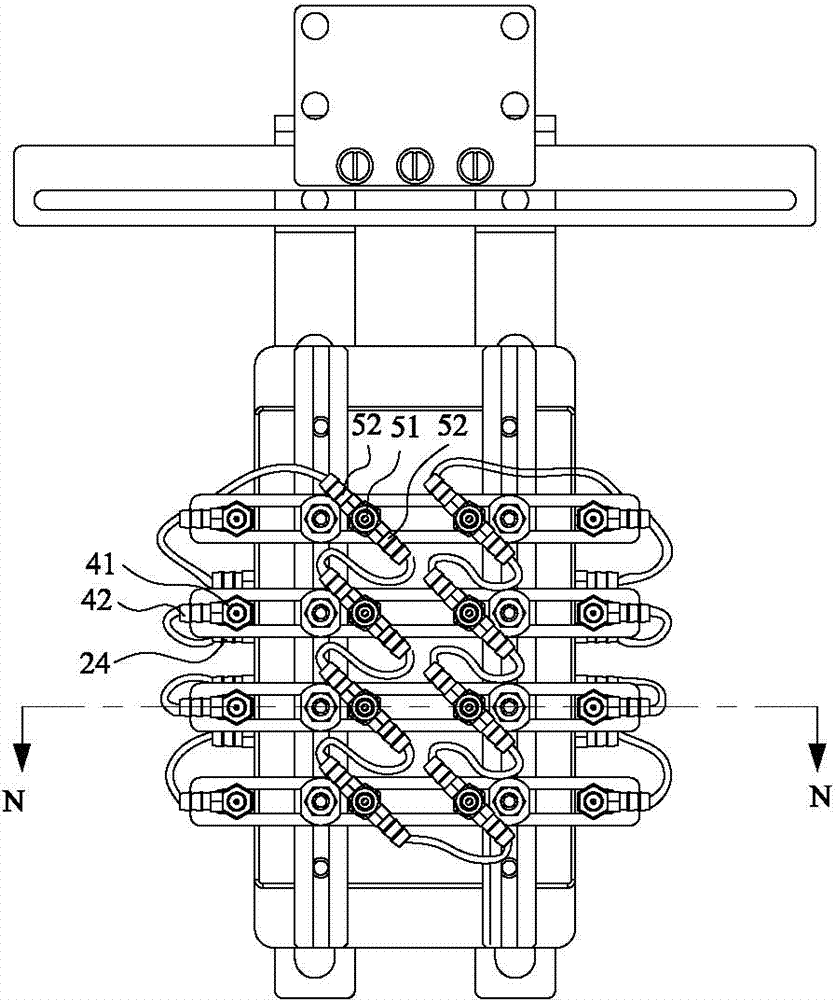

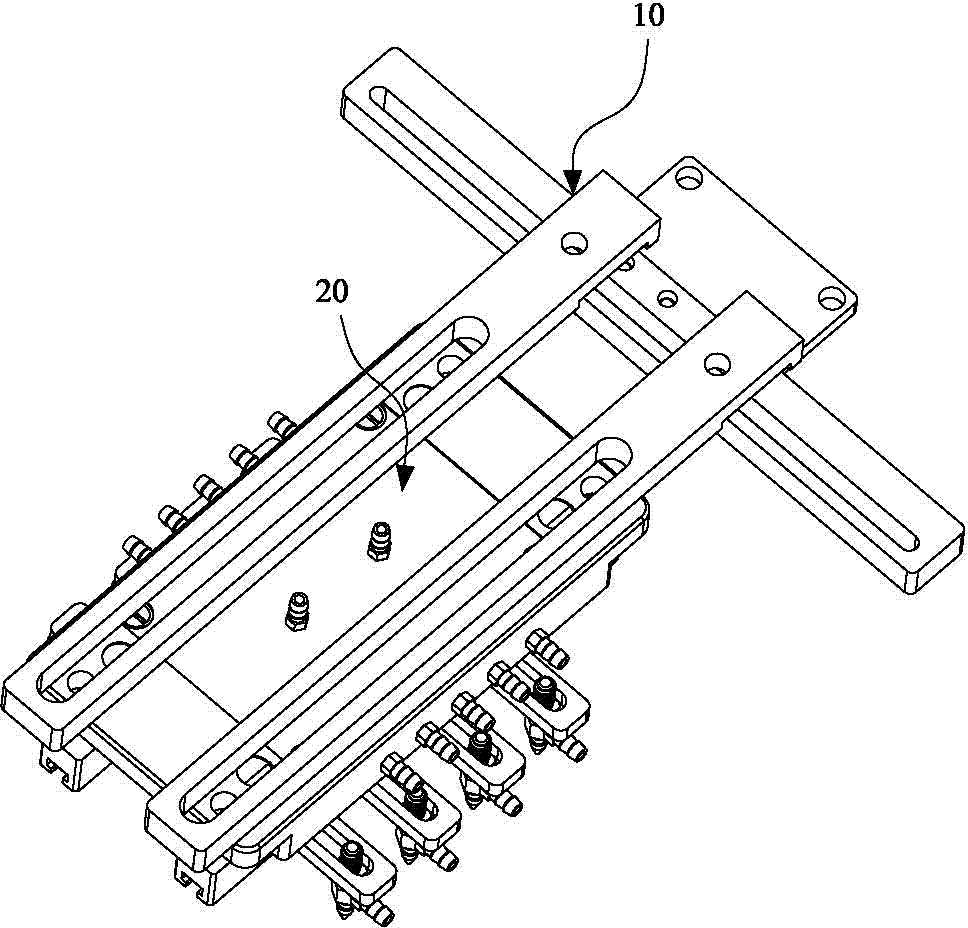

[0052] Please refer to Figure 1 to Figure 9 As shown, it shows the specific structure of the preferred embodiment of the present invention, the automatic vacuum suction key fixture includes a base 10, a vacuum table 20, a suction nozzle assembly mounting base 30, several first suction nozzles Assembly 40 and the second suction nozzle assembly 50.

[0053] Among them, such as Figure 4As shown, the base 10 includes a fixedly installed Y-direction beam 11 and an X-direction beam 12 arranged parallel to each other at intervals. The X-direction beam 12 is connected to the Y-direction beam 11 and can move along the Y-axis. The middle part of the upper end of the Y-direction beam 11 of the base 10 is fixed on a mounting plate 13, and the Y-direction beam 11 is provided with a Y-direction long sliding hole 111; the X-direction beam 12 is provided with an X-direction long sliding hole 121, the end of the X-direction beam 12 is provided with a groove 122, and the end of the X-direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com