Charging pile component line sequence color mistake-proofing detection method

A detection method and technology of charging piles, which are applied in neural learning methods, computer components, image data processing, etc., can solve the problems of low detection efficiency and high false detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

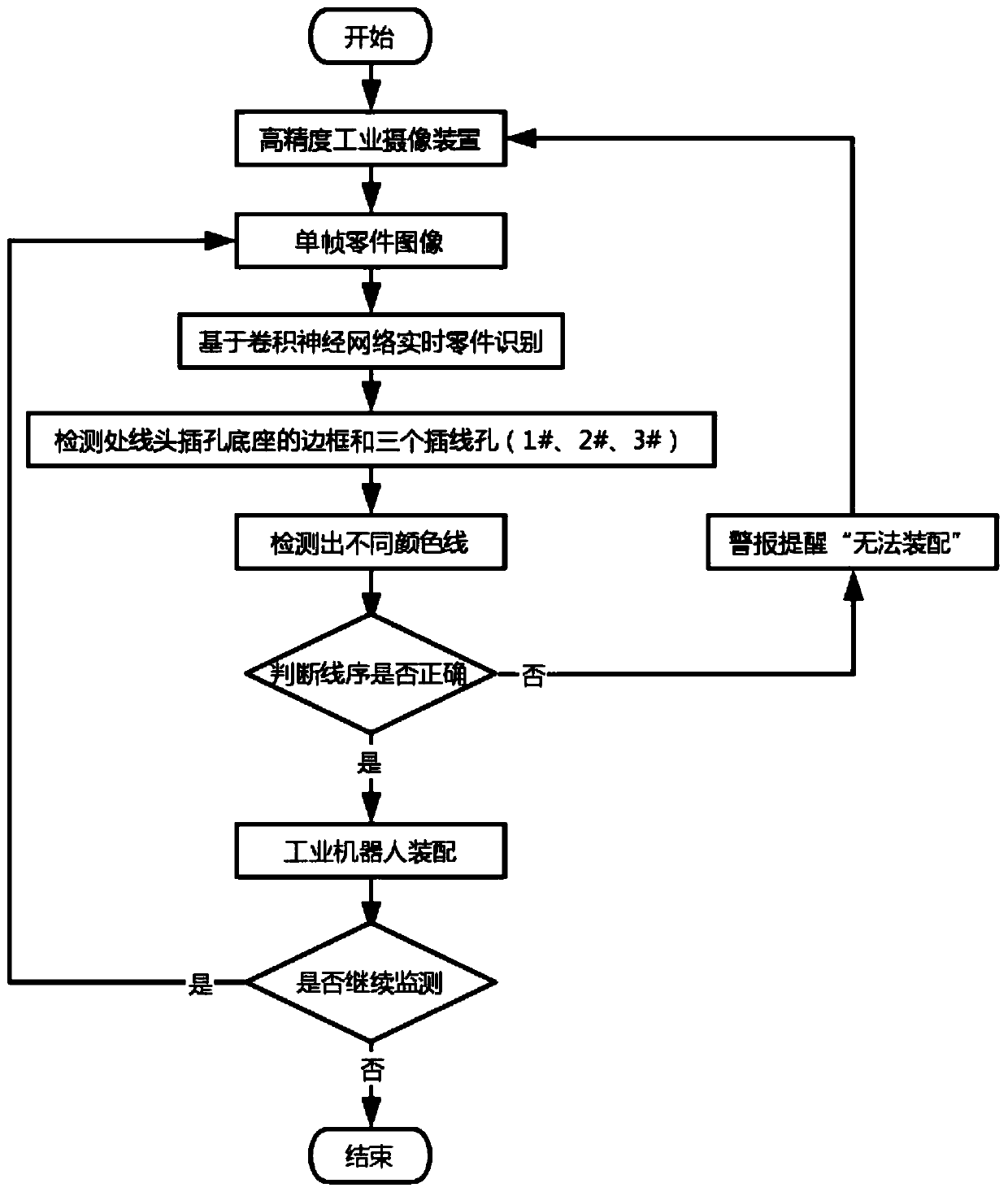

[0041] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

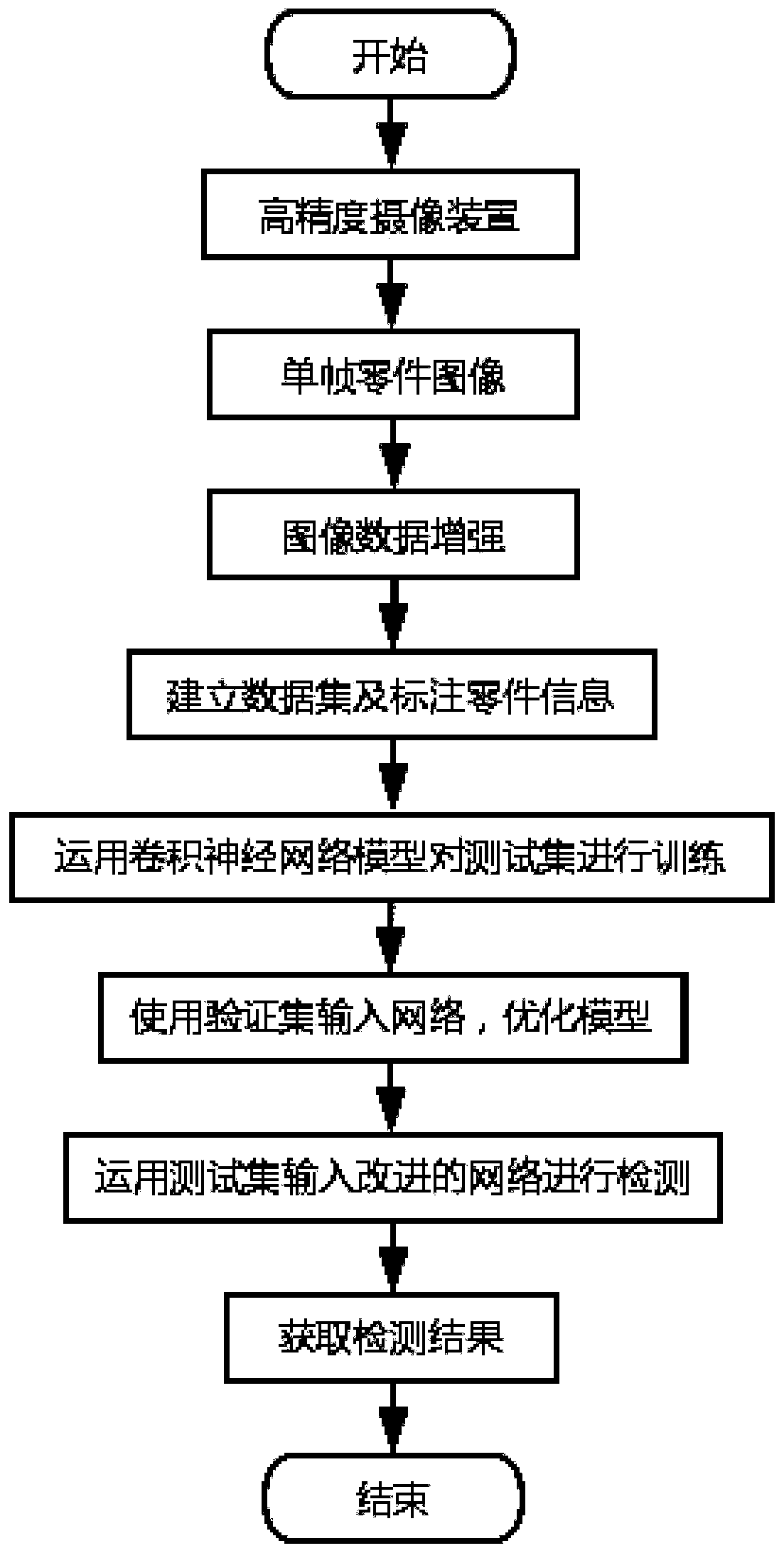

[0042] An error-proof detection method for the line sequence color of charging pile parts, such as figure 1 shown, including the following steps:

[0043] Step 1. Collect the line sequence and color video samples of charging pile parts;

[0044] In this embodiment, a high-precision camera is used to collect the line sequence and color video samples of the charging pile parts, and according to needs, the collected objects can also be expanded to video samples of other shapes of specific objects in the charging pile parts.

[0045] Step 2. Obtain the single-frame image of the line sequence and color video sample of the charging pile parts collected in step 1 to form a basic data set; and perform data enhancement on the image of the basic data set to form a charging pile part data set; The location and category information of the charging pile parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com