Catalyst for producing clean fuel oil by using coal tar and preparation method of catalyst

A production method and catalyst technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as unsatisfactory effects, achieve ideal quality, improve Stability and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

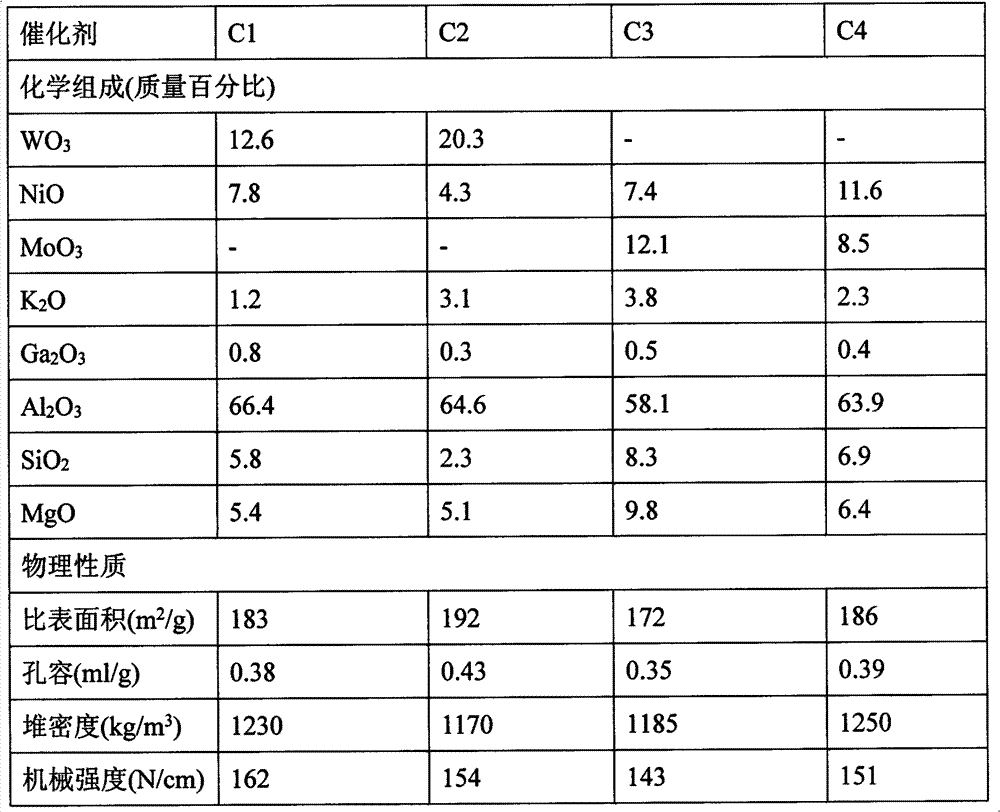

Embodiment 1

[0040] Using the equal volume impregnation method, dissolve 50.21g ethyl orthosilicate in an appropriate amount of absolute ethanol, add 132.80g Al 2 o 3 , impregnated at room temperature for 4h, dried at 120°C for 8h after impregnated, and calcined at 800°C for 4h after hydrolysis to obtain the desired silica-alumina carrier. Add 68.7g of magnesium nitrate hexahydrate to the prepared silica-alumina carrier, add peptizer accounting for 2.3% of the total mass of the solid, a binder accounting for 1.8% of the total mass of the solid, and an extrusion aid accounting for 3.9% of the total mass of the solid, kneading After the plastic is formed, it is extruded with a cylindrical hole-extruding abrasive tool, with a diameter of 3.5 mm and a length of 5.0 mm. Dry in an oven at 120°C for 8 hours, and bake at 800°C for 4 hours to obtain the final shaped carrier.

[0041] Prepare 27.56g of ammonium tungstate and 60.72g of nickel nitrate hexahydrate into an aqueous solution, impregnate...

Embodiment 2

[0043] Using the equal volume impregnation method, dissolve 15.95g ethyl orthosilicate in an appropriate amount of absolute ethanol, add 129.20g Al 2 o 3 , impregnated at room temperature for 4h, dried at 120°C for 8h after impregnated, and calcined at 800°C for 4h after hydrolysis to obtain the desired silica-alumina carrier. Add 34.26g magnesium carbonate trihydrate in the prepared silica-alumina carrier, add the peptizing agent accounting for 1.6% of the total solid mass, account for the binder of 1.2% of the total solid mass, account for the extrusion aid of 2.7% of the total solid mass, and knead After being made into a plastic object, it is molded with a clover hole-extruding abrasive tool, and the diameter of the clover is 3.5 mm. Dry in an oven at 120°C for 8 hours, and bake at 800°C for 4 hours to obtain the final shaped carrier.

[0044] Prepare 57.86g of sodium tungstate and 33.48g of nickel nitrate hexahydrate into an aqueous solution, impregnate the molded carri...

Embodiment 3

[0046] Using the equal volume impregnation method, dissolve 57.55g of ethyl orthosilicate in an appropriate amount of absolute ethanol, add 116.20g of Al 2 o 3 , impregnated at room temperature for 4h, dried at 120°C for 8h after impregnated, and calcined at 800°C for 4h after hydrolysis to obtain the desired silica-alumina carrier. Add 104.29g of magnesium acetate tetrahydrate in the prepared silica-alumina carrier, add the peptizer accounting for 4.7% of the total solid mass, account for the binder of 2.1% of the total solid mass, account for the extrusion aid of 3.3% of the total solid mass, and knead After the plastic is formed, it is extruded with a cylindrical hole-extruding abrasive tool, with a diameter of 3.5 mm and a length of 5.0 mm. Dry in an oven at 120°C for 8 hours, and bake at 800°C for 4 hours to obtain the final shaped carrier.

[0047] 29.68g of ammonium molybdate and 23.52g of nickel carbonate were formulated into an aqueous solution, and the molded carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com