Combustion appliance for raising the temperature of exhaust gas

A burner and exhaust gas technology, which is applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of exhaust gas flow change, burner flameout, incomplete combustion, etc., to improve combustibility, improve combustibility, prevent flameout or incomplete burn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

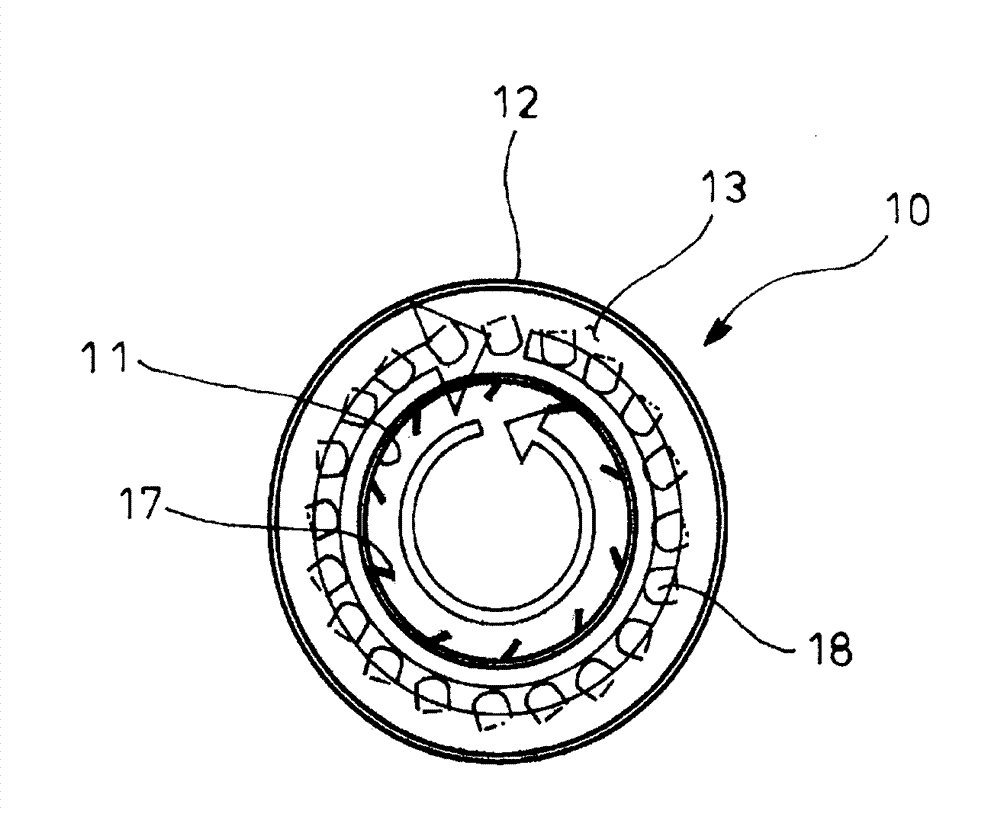

[0035] Embodiments of the present invention will be described below with reference to the drawings.

[0036] figure 1 represents an embodiment of the present invention, figure 1 Reference numeral 1 in the figure indicates an exhaust pipe 2 that guides the exhaust gas 1 after passing through the turbine of a turbocharger (not shown), and the curved portion of the exhaust pipe 2 that is bent into an L shape is equipped with a nozzle that can pass through the exhaust pipe 2. A burner 3 for raising the temperature of the exhaust gas 1 is obtained by combusting a flame.

[0037]Here, the bent portion of the exhaust pipe 2 is constituted by a casing 4 disposed approximately at right angles to the exhaust pipe 2 from the upstream side and directed toward the downstream side in the flow direction of the exhaust gas 1 . The filter 3 is accommodated in the casing 4, and the particulate filter 6 held by the other casing 5 is interposed between the casing 4 and the exhaust pipe 2 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com