Method for determining the degree of saturation of solid ammonia storage materials in containers

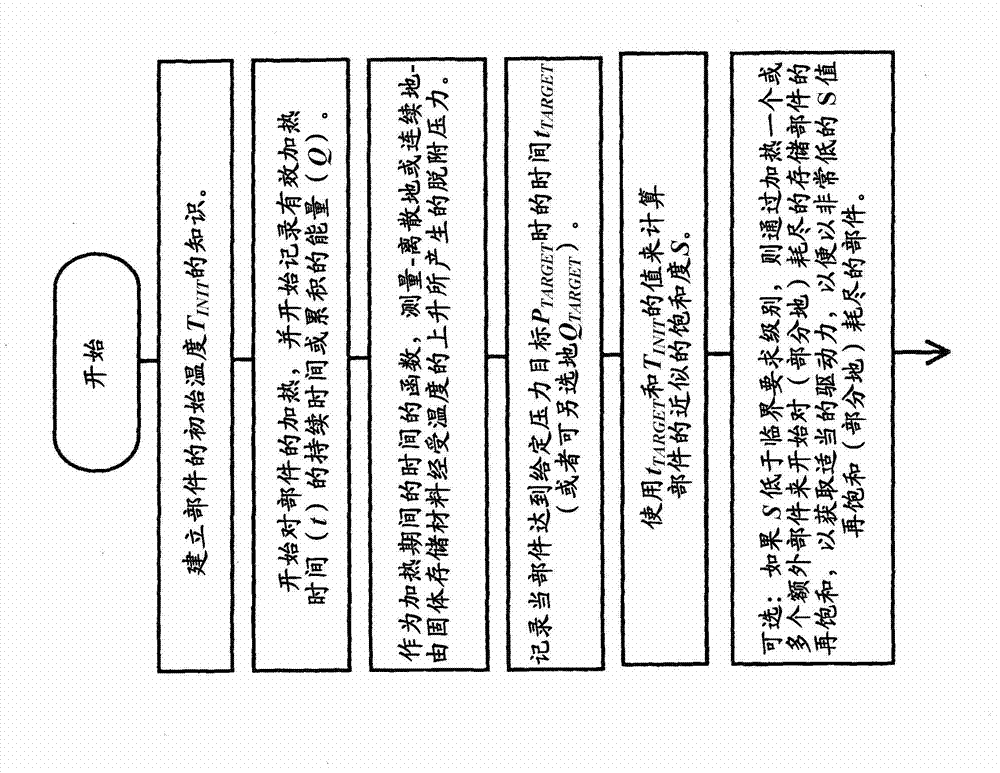

By recording the heating time and desorption pressure, combined with the initial temperature and target pressure, the saturation degree of the solid ammonia storage material is calculated, which solves the problem of difficulty in determining the saturation degree in the existing technology, optimizes the ammonia resaturation process, and ensures NOx conversion performance and fuel efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

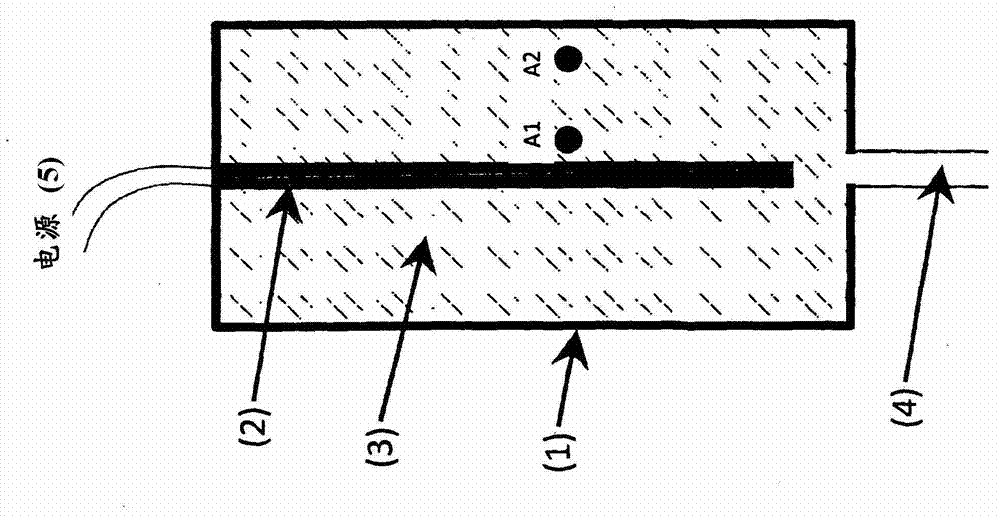

[0038] Figure 1A An example of a device in which the present invention can be applied is shown. The storage container 1, which can be made of, for example, steel or aluminum, contains a heating element 2 inside the storage material 3, and the container has an outlet pipe 4 that allows ammonia to flow out during the desorption process by heating. It also allows supply from different Source (e.g., larger storage container 10( Image 6 )) The pressure of ammonia to resaturate the storage material. The heater may be an electric heater having a power source 5. Using the pressure sensor 8 connected to the pipe 4 ( Image 6 Shown) to perform pressure measurement.

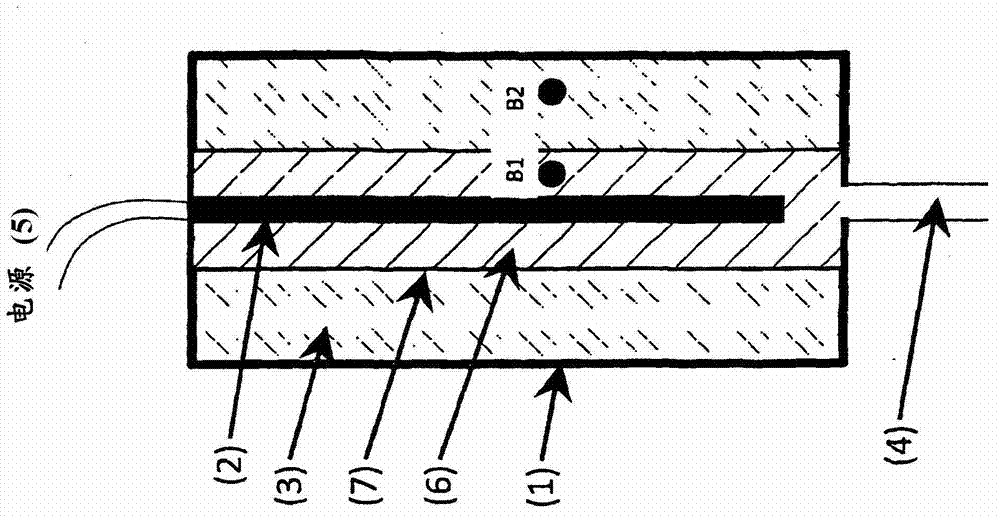

[0039] Figure 1B The same part is shown, but here the storage material is partially degassed after some ammonia has been desorbed by heating the part. The degassing part 6 is usually closest to the heat source, while the saturated material 3 is far away from the heat source. Line 7 shows the front, where the material is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com