Thermally driven transmission electron microscope grid made of intelligent composite material

An electron microscope and composite material technology, which is applied to circuits, discharge tubes, electrical components, etc., and can solve the problems of limited pure axial strain, inability to meet large strains, and inability to achieve biaxial and large-angle tilting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

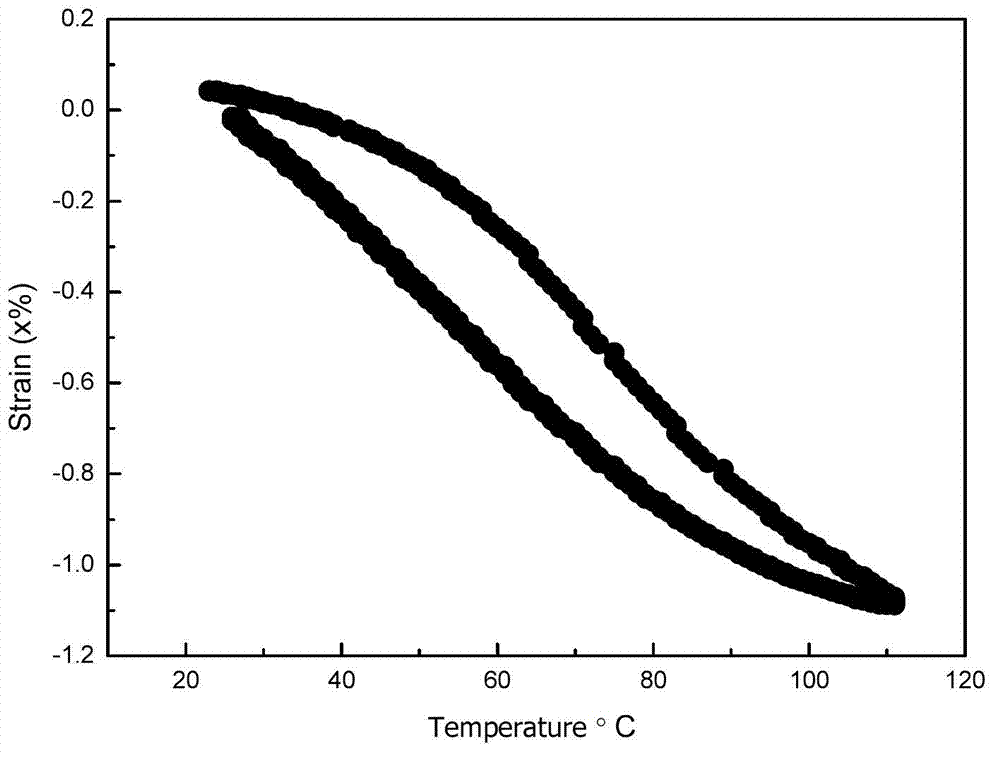

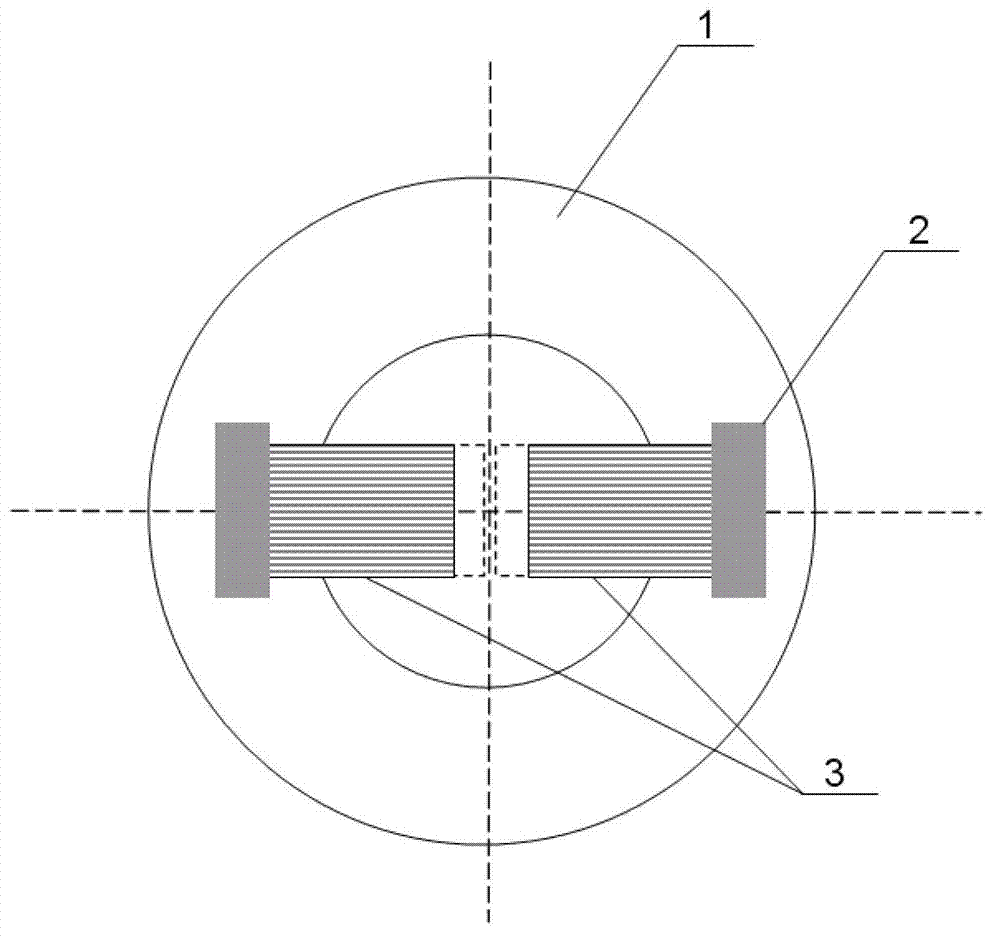

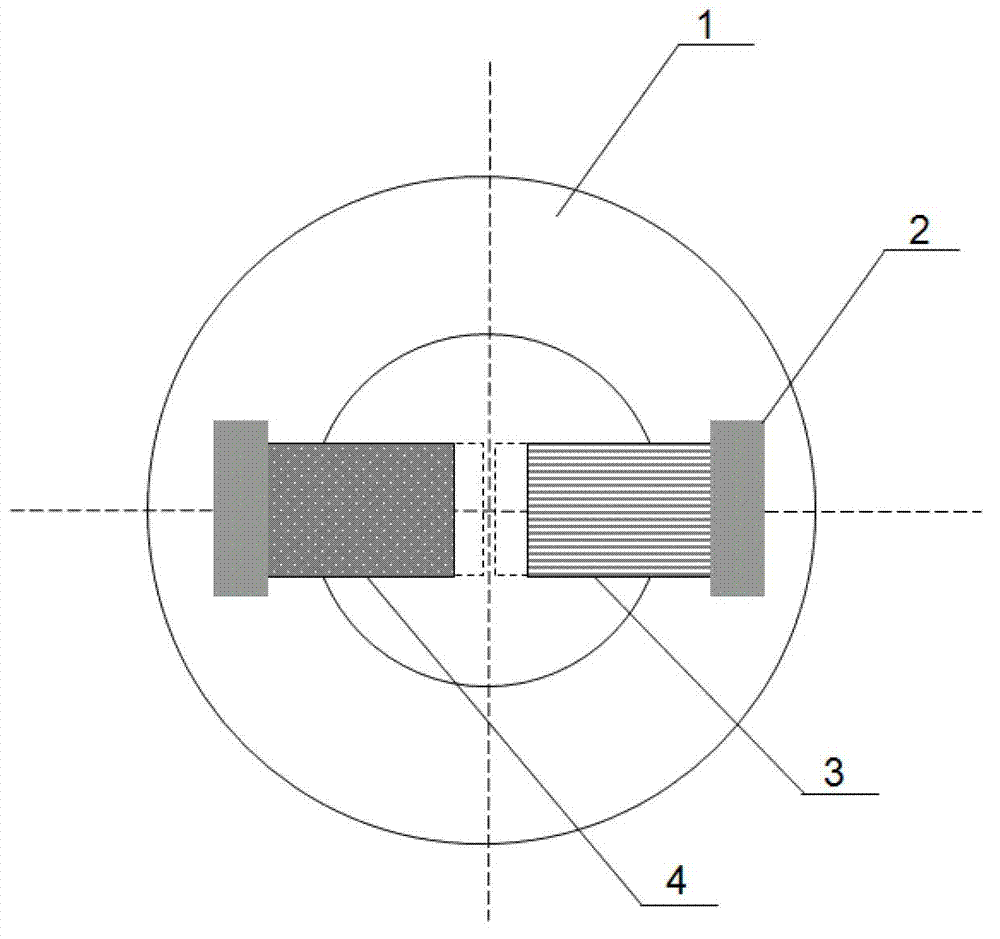

[0038] This embodiment provides a bidirectionally driven transmission electron microscope grid composed of two composite material sheets, and its manufacturing method includes the following steps:

[0039] 1. Pretreatment: The composite sheet used is a wire with an original diameter of 0.5mm and a length of 100mm, and the composition is Nb 20 Ti 42 Ni 38 . Stretch 10% at room temperature through a tensile testing machine (strain rate 0.05mm / s) and then unload (pre-strain process), then heat the entire wire through an annealing furnace from room temperature to 160°C, then take it out and cool it to room temperature in air , The heating rate of the process is 5°C / min (preheating process).

[0040] 2. Fabrication of the carrier net: the pretreated wire is processed into a small cylinder with a length of 1mm and a diameter of 0.5mm by a slow-speed saw, and then manually polished to a rectangular piece with a length of 1mm, a width of 0.5mm, and a thickness of 0.1mm to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com