Magnetic suspension collecting and blow-drying device and application thereof on magnetic particle inspection equipment

A technology of magnetic particle flaw detection and magnetic suspension liquid, which is applied in the direction of material magnetic variable, etc., can solve the problems that magnetic suspension liquid cannot be collected effectively, rust, and the surface of the steel to be inspected is wet, etc., so as to improve the appearance quality, reduce the cost, and improve the appearance quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

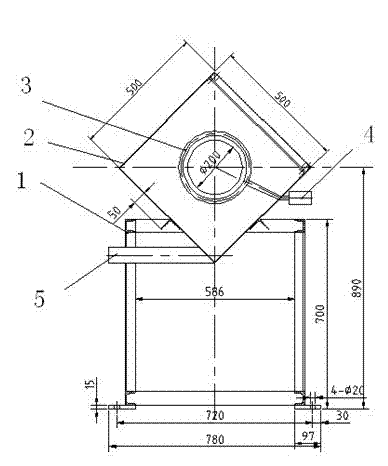

[0016] A magnetic suspension collecting and drying device according to the present invention, see figure 1 , the device includes a frame 1, a box body 2 is arranged on the frame 1, and a circular air jet pipe 3 is arranged in the box body 2, and the central elevation of the circular air jet pipe 3 is consistent with the central elevation of the magnetic particle inspection steel. ; The circular jet pipe 3 is connected to the gas source through the solenoid valve 4; the recovery pipe 5 used to collect the magnetic suspension is provided at the bottom of the box 2. The box body is arranged on the rack in a rhombus shape, and the circular air jet pipe is located at the center of the box body; the recovery pipe is located at the bottom of the diamond-shaped box body at the lowest point. The recovery pipe is connected with the magnetic suspension storage tank.

[0017] The application of a magnetic suspension liquid collection and drying device on magnetic particle flaw detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com