Multifunctional color-focus fabric for umbrella and coating method thereof

A multi-functional and fabric technology, applied in the field of fabric processing, can solve the problems of deep color fabrics, easy to produce defective products, and the appearance of the surface layer of fabrics is not gorgeous enough, so as to achieve gorgeous glue surface effects, low defective rate, and rich colors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

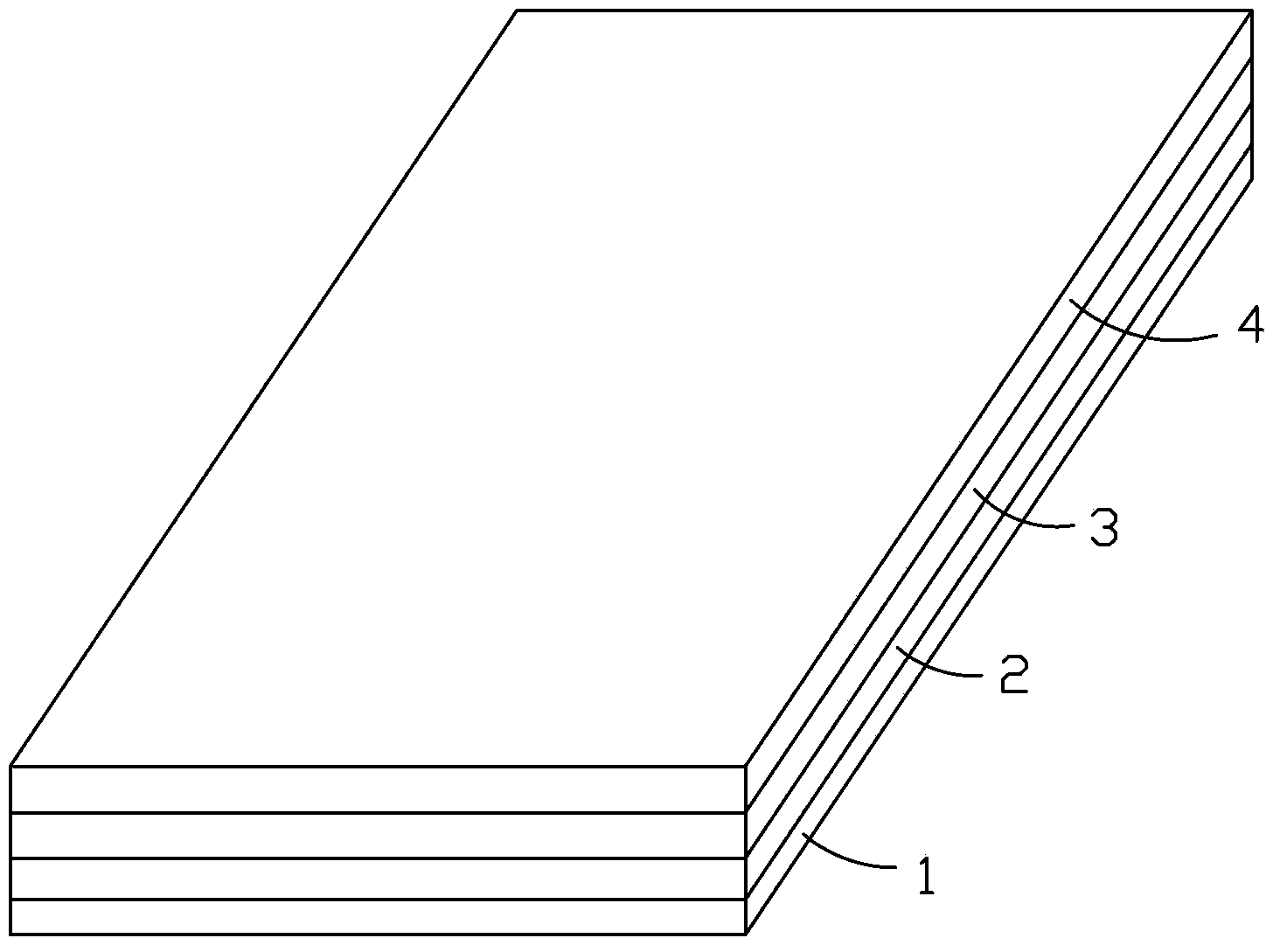

[0028] refer to figure 1 , a kind of multi-functional colorful fabric for umbrella of the present invention, comprises base cloth 1, and described base cloth adopts high-density yarn-dyed black polyester spinning fabric, and the number of warp threads and weft threads per square inch is not less than 250 , the base cloth 1 is coated with a black glue layer 2, a silver glue layer 3 and a mirror pearl layer 4 in sequence; the black glue layer is composed of 60-70wt% acrylate, 1.7-2.2wt% frame Bridging agent, 10-15wt% toluene and 17-22wt% black paste, the total amount of the above components is 100%; the silver glue layer is composed of 50-60wt% acrylate, 1.5-1.8wt% bridging agent, 20-25wt% toluene and 15-25wt% silver paste, the total amount of the above components is 100%; the mirror pearlescent layer is composed of 45-52wt% polyamide resin, 1.3-25wt% 1.7wt% bridging agent, 25-35wt% toluene, 16-23wt% pearlescent and 1.3-1.7wt% anti-tacking agent, the total amount of the above c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com