Waste continuous solid fermenting reacting device and solid fermenting method

A solid-state fermentation and reaction device technology, applied in solid-phase fermentation bioreactors, biochemical equipment and methods, gas production bioreactors, etc., can solve the problem of uneven mixing of fermentation substrates and bacteria, reduce fermentation production efficiency, The problem of uneven distribution of fermentation substrates, to achieve the effect of strengthening the solid-state fermentation reaction process, the device structure is simple, and the fermentation speed is accelerated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The cultivation of embodiment 1 microbial catalyst

[0051] The microbial catalyst strain is an enriched anaerobic methanogenic microbial flora, the culture temperature is 37°C, the culture environment is anaerobic, and the culture time is 25 days.

[0052] The medium formula required for cultivation is (g / L):K 2 HPO 4 0.4, KH 2 PO 4 0.4, NH 4 Cl1.0, MgCl 2 1.0, yeast extract 1.0, cysteine 0.5. 0.1% resazurin 2.0mL, trace element solution 10.0mL, vitamin solution 10.0mL.

[0053] The composition of above-mentioned trace element solution is (g / L):MgSO 4 ·7H 2 O3.0, CoCl 2 0.1, MnSO 4 2H 2 O0 5, CaC1 2 2H 2 O0.1, ZnSO 4 ·7H 2 O0.1, NaCl1.0, FeSO 4 ·7H 2 O0.1, CuSO 4 ·5H 2 O0.01, KAl(SO 4 ) 2 0.01,H 3 BO 3 0.01, NaMoO 4 2H 2 O0.01.

[0054] The composition of above-mentioned vitamin solution is (mg / L): Thiamine (B l )5.0, calcium pantothenate 5.0, riboflavin (B 2 )5.0, biotin 2.0, folic acid 2.0, Bl:0.1, niacin 5.0, p-aminobenzoic acid 5.0, lip...

Embodiment 2

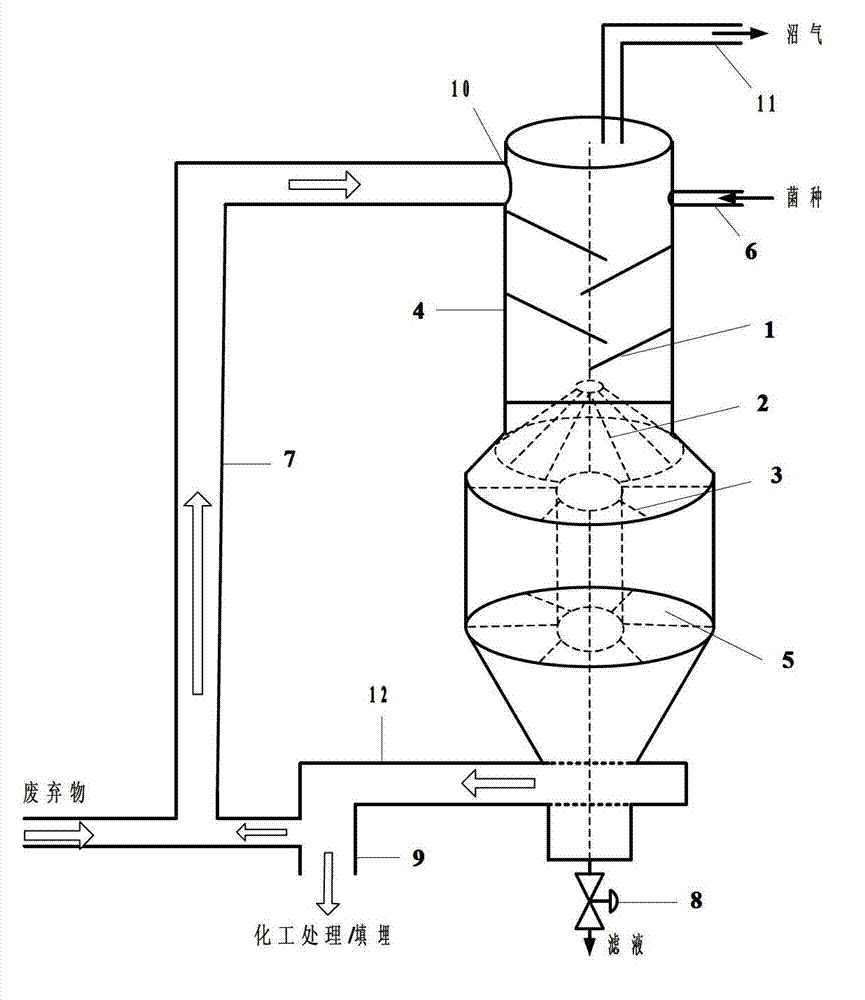

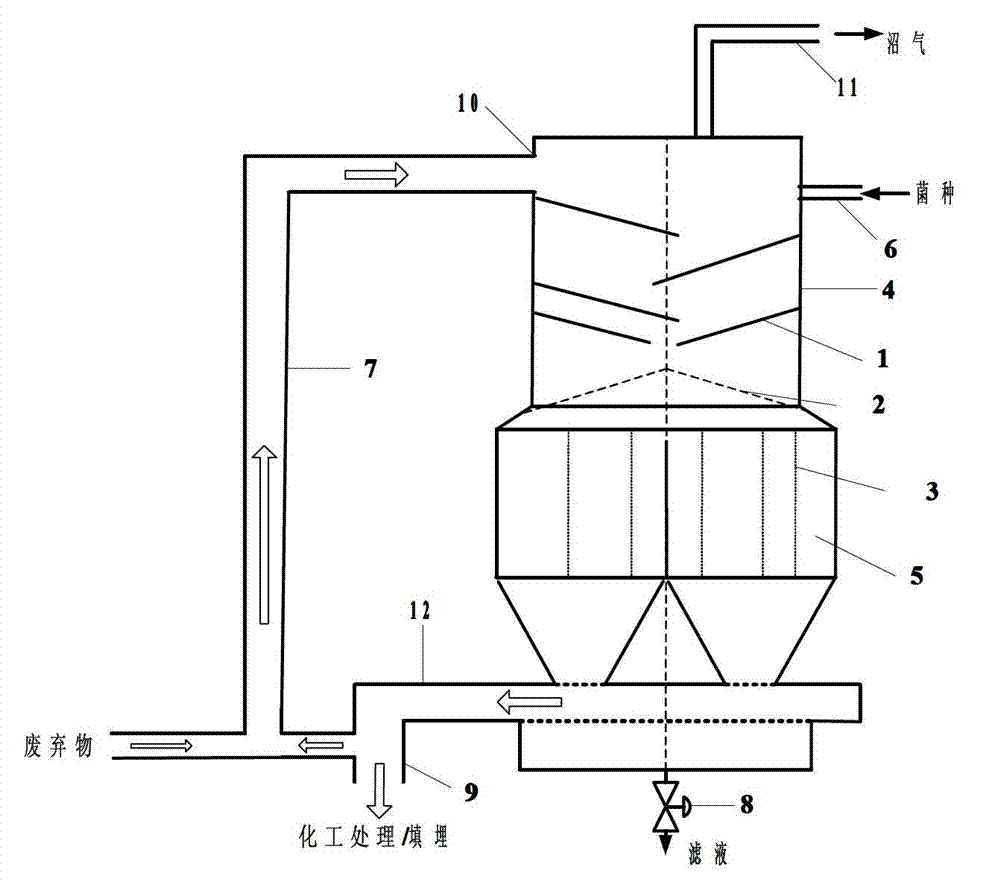

[0056] Example 2 Microbial anaerobic treatment of kitchen waste to produce biogas

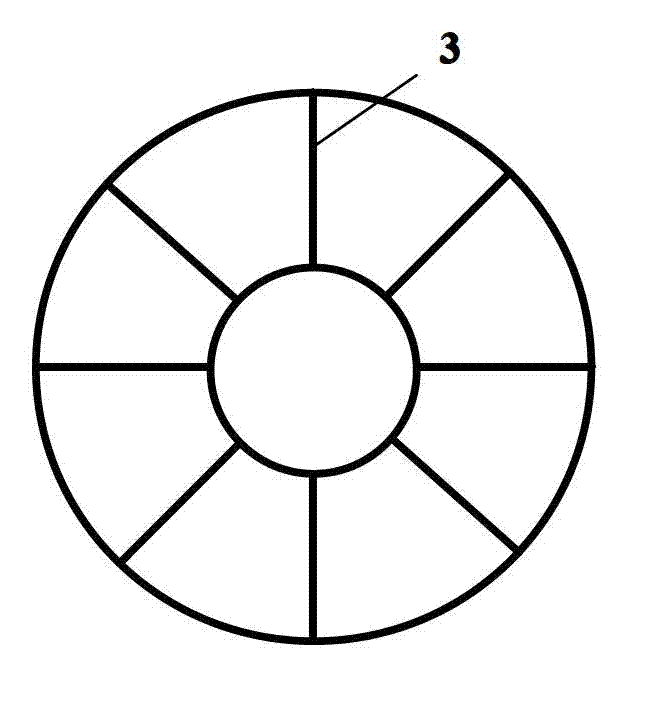

[0057] First, the collected kitchen waste is extruded to remove most of the water, and the microbial catalyst cultivated in the above-mentioned embodiment 1 is centrifugally concentrated by a high-speed centrifuge, and 0.1 kg of the microbial catalyst with a concentration of 25 g dry cells / L is mixed with 5 kg of extruded The compressed kitchen waste is fully mixed and fermented in a circular solid-state fermentation reactor. The reactor is divided into 6 equal parts by internal components. The fermentation temperature is 37°C, the fermentation time is 18 days, and the fermentation pressure is normal pressure. Separated to produce 52.3 liters of biogas.

Embodiment 3

[0058] Example 3 Production of biogas by anaerobic fermentation of distiller's grains

[0059] The microbial catalyst cultivated in the above-mentioned Example 1 was centrifuged and concentrated by a high-speed centrifuge for subsequent use. Install a certain rate into the solid-state fermentation reactor, and mix evenly with a certain rate of microbial strains through the baffle. The concentration of the microbial catalyst is 1g dry cells / L, the quality is 2kg, and the amount of distiller's grains is 10kg. In the square solid-state fermentation reaction Fermentation in the container, the square reactor is divided into 8 equal parts by the internal components, the fermentation temperature: 37 ° C, the fermentation time is 30 days, the pressure of the fermentation is normal pressure, the fermentation product is separated, the collected gas volume is 150L, and the final quality of the fermentation product is 3kg, achieving volume reduction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com