Nanometer oxide coated phosphate rust resisting pigment and preparation method thereof

A nano-oxide and nano-scale oxide technology, which is used in chemical instruments and methods, anti-corrosion coatings, inorganic pigment treatment, etc., can solve the high cost of phosphate anti-rust pigments, the widespread use of non-toxic anti-rust pigments and the limitations of promotion, etc. problem, to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

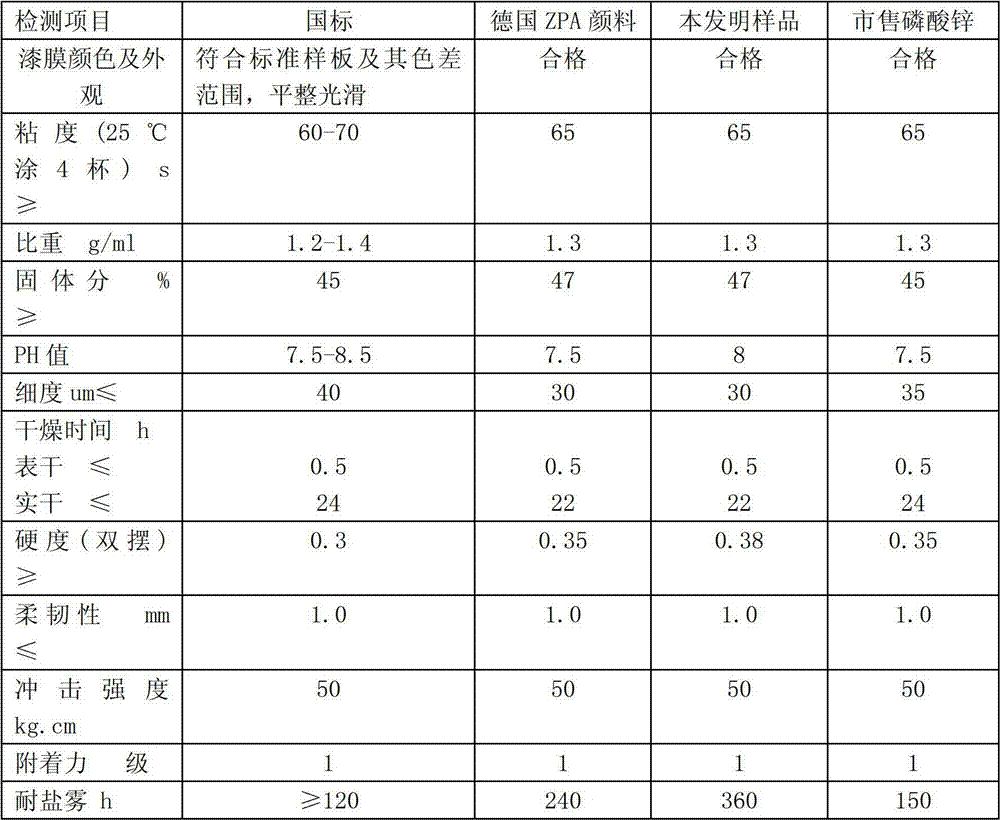

Examples

Embodiment 1

[0037] The preparation method of antirust pigment of the present invention:

[0038] 1: Weigh 22.3g of calcium hydroxide [Ca(OH) 2 ], slowly add 200ml of water, stir well until the emulsification is uniform.

[0039] 2: Measure 14ml of concentrated phosphoric acid with a concentration of 85%, slowly add 28ml of water, and stir evenly.

[0040] 3: Slowly add the diluted phosphoric acid to the calcium hydroxide emulsion while stirring. After the dropwise addition, the stirring reaction was continued at normal temperature for 2 hours to stop, and the calcium phosphate intermediate emulsion was obtained.

[0041] 4: Titanium oxysulfate (TiOSO 4 ) 3.2g into 100ml of water, dissolved for later use.

[0042] 5: Weigh 2.86g of calcium hydroxide, add 50ml of water and stir to form an emulsion for later use.

[0043] 6: Add the titanyl sulfate solution prepared in step 4 to the calcium phosphate intermediate emulsion prepared in step 3, mix evenly and drop into the calcium hydroxid...

Embodiment 2

[0046] The preparation method of antirust pigment of the present invention:

[0047] 1: Weigh 30g of calcium carbonate [CaCO 3 ], slowly add 200ml of water, stir well until the emulsification is uniform.

[0048] 2: Measure 14ml of concentrated phosphoric acid with a concentration of 85%, slowly add 28ml of water, and stir evenly.

[0049] 3: Slowly add the diluted phosphoric acid to the calcium hydroxide emulsion while stirring. After the dropwise addition, the stirring reaction was continued at normal temperature for 2 hours to stop, and the calcium phosphate intermediate emulsion was obtained.

[0050] 4: Titanium oxysulfate (TiOSO 4 ) 3.2g into 100ml of water, dissolved for later use.

[0051] 5: Weigh 2.86g of calcium hydroxide, add 50ml of water and stir to form an emulsion for later use.

[0052] 6: Add the titanyl sulfate solution prepared in step 4 to the calcium phosphate intermediate emulsion prepared in step 3, mix evenly and then drop into the calcium hydroxi...

Embodiment 3

[0055] The preparation method of antirust pigment of the present invention:

[0056] 1: Weigh 16.8g of calcium oxide [CaO], slowly add 200ml of water, stir well until the emulsification is uniform.

[0057] 2: Measure 14ml of concentrated phosphoric acid with a concentration of 85%, slowly add 28ml of water, and stir evenly.

[0058] 3: Slowly add the diluted phosphoric acid to the calcium hydroxide emulsion while stirring. After the dropwise addition, the stirring reaction was continued at normal temperature for 2 hours to stop, and the calcium phosphate intermediate emulsion was obtained.

[0059] 4: Titanium oxysulfate (TiOSO 4 ) 3.2g into 100ml of water, dissolved for later use.

[0060] 5: Weigh 2.86g of calcium hydroxide, add 50ml of water and stir to form an emulsion for later use.

[0061] 6: Add the titanyl sulfate solution prepared in step 4 to the calcium phosphate intermediate emulsion prepared in step 3, mix evenly and then drop into the calcium hydroxide emul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com