Method for synthesizing cyclic carbonate

A compound and carbon atom technology, applied in the field of catalytic synthesis of fine chemical products, can solve the problems of high cost, difficult separation of catalysts and products, etc., achieve stable properties, easy separation and recovery, and save production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

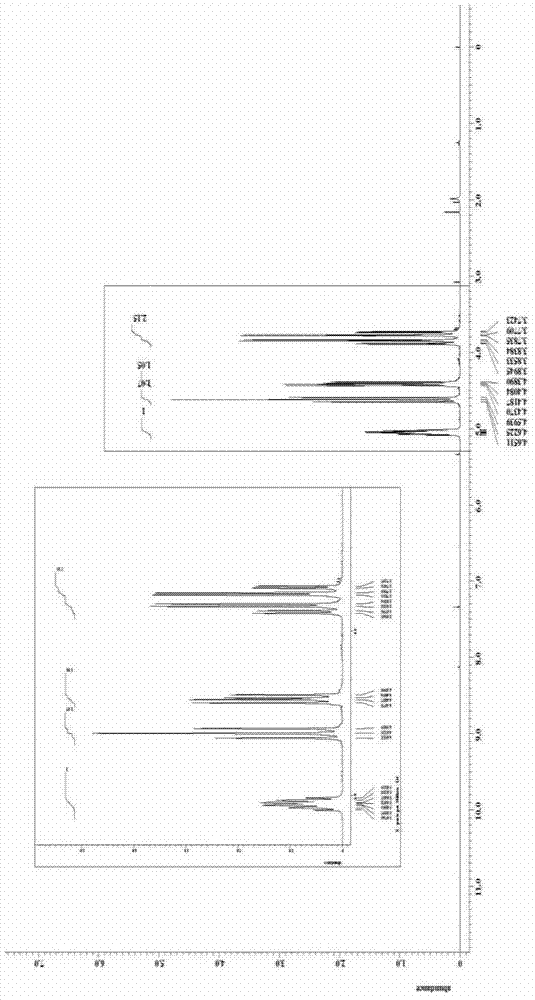

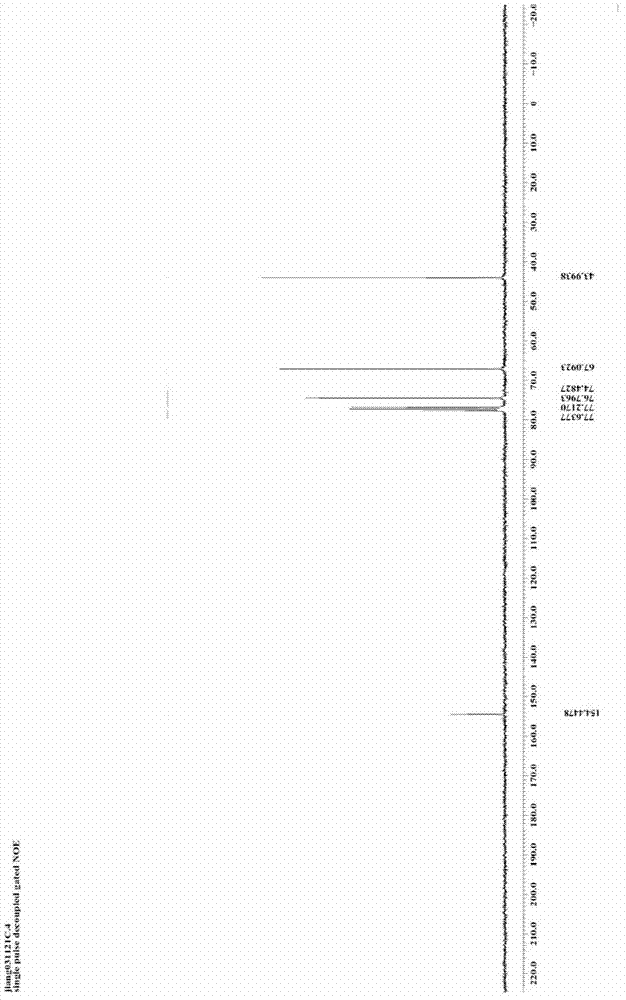

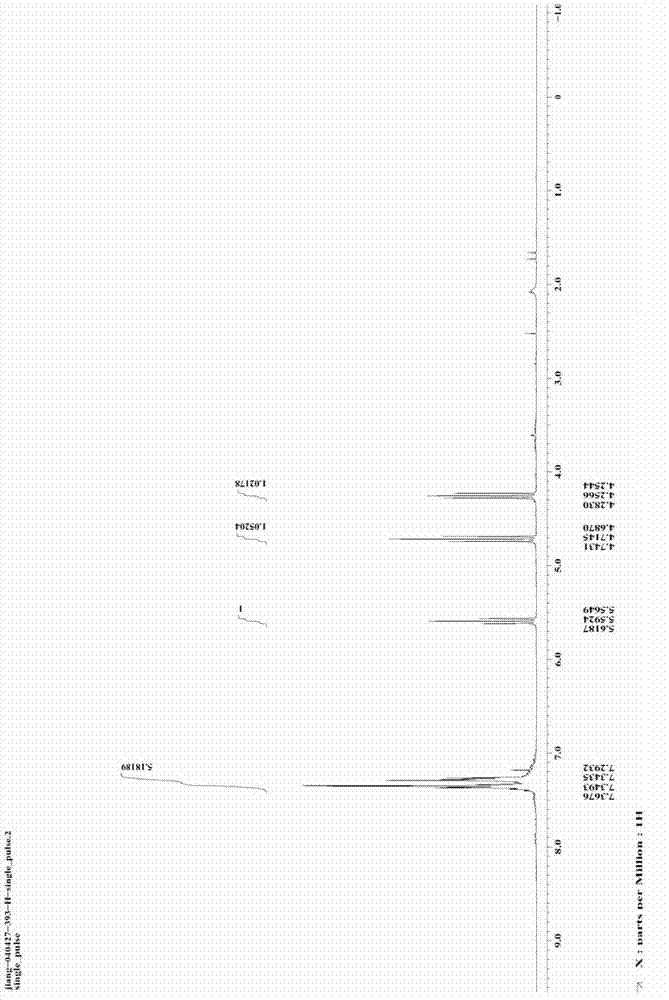

[0037] 0.116 g (0.5 mmol) of terpyridine and 0.463 g (5 mmol) of epichlorohydrin were respectively measured and added to a 25-mL stainless steel autoclave. After sealing the reactor, it was filled with 30 atm carbon dioxide at 25°C. Stir, heat to 150°C, keep warm and react for 20h. Then cool to room temperature and vent. Reaction result: The yield of chloropropylene carbonate was 91%.

[0038] The hydrogen nuclear magnetic spectrum of the product obtained in this example is as figure 1 As shown, the carbon spectrum is as figure 2 As shown, it can be seen from the figure that the product has a correct structure and is represented by formula I chloropropylene carbonate.

Embodiment 2

[0040] 0.116 g (0.5 mmol) of terpyridine and 0.463 g (5 mmol) of epichlorohydrin were respectively measured and added to a 25-mL stainless steel autoclave. After sealing the reactor, it was filled with 30 atm carbon dioxide at 25°C. Stir, heat to 160°C, keep warm and react for 20h. Then cool to room temperature and vent. Reaction result: The yield of chloropropylene carbonate was 88%.

[0041] The NMR results of the product obtained in this example are exactly the same as in Example 1, and will not be repeated here.

Embodiment 3

[0043] 0.116 g (0.5 mmol) of terpyridine and 0.463 g (5 mmol) of epichlorohydrin were respectively measured and added to a 25-mL stainless steel autoclave. After sealing the reactor, it was filled with 30 atm carbon dioxide at 25°C. Stir, heat to 110°C, keep warm and react for 20h. Then cool to room temperature and vent. Reaction result: The yield of chloropropylene carbonate was 76%.

[0044] The NMR results of the product obtained in this example are exactly the same as in Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com