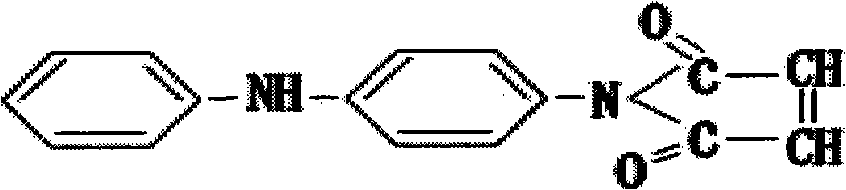

Composition of N-4(anilinophenyl)maleimide and preparation method thereof

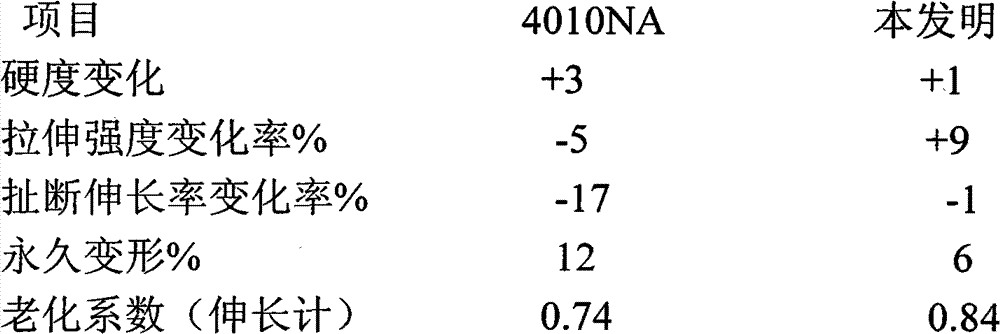

An anilinophenyl, maleimide technology, applied in the composition and preparation, the reactive type does not draw out the antioxidant, the composition and preparation field of N-4 maleimide, can solve the complex production method, The problems of large environmental pollution and high product cost can achieve the effects of simple method, prolonged scorch time, and reduced toxicity and pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

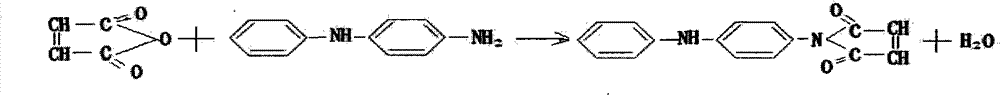

Method used

Image

Examples

Embodiment 1

[0029] The raw material composition used and the proportioning by weight are:

[0030] 100 g of acetone, 30 g of tetraaminodiphenylamine, 50 g of maleic anhydride, and 30 g of acetic anhydride.

[0031] Add 30g of tetraaminodiphenylamine into a 500ml three-necked flask, fix the three-necked flask, install the stirrer and thermometer, then add 100g of acetone solvent, stir to completely dissolve the tetraaminodiphenylamine, then add 50g of maleic anhydride dropwise, At this time, it is an exothermic reaction and attention should be paid to cooling down. The temperature is controlled at about 20°C. After the dropwise addition is completed, it is kept at 50°C for 2 hours, then 30g of acetic anhydride is added and kept at 25-30°C for 3 hours. After the reaction is completed, the acetone is recovered by evaporation. Finally, the coarse product is obtained by centrifugal washing, and the finished product is dried and pulverized. Weighing 56g, taking tetraaminodiphenylamine as a st...

Embodiment 2

[0043] The raw material composition used and the proportioning by weight are:

[0044] 200g of acetone, 60g of tetraaminodiphenylamine, 100g of maleic anhydride, and 60 parts of acetic anhydride.

[0045] Add 60g of tetraaminodiphenylamine and 100g of maleic anhydride to a 1000ml three-necked flask, fix the three-necked flask, install the stirrer and thermometer, then add 200g of acetone, stir to completely dissolve the maleic anhydride, and then add 100g dropwise For maleic anhydride, it is an exothermic reaction at this time. Pay attention to lowering the temperature. The temperature is controlled at about 20°C. After the dropwise addition is completed, keep it at 55°C for 2 hours, then add 60g of acetic anhydride and keep it at 25-30°C for 3 hours. After that, the reaction is complete. Evaporation and recovery of acetone. Finally, the coarse product is obtained by centrifugal washing, and the finished product is dried and pulverized. Weighing 113g, taking tetraaminodiphen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com