Aged garbage slag powder haydite and manufacturing method thereof

A manufacturing method and technology of garbage residue, applied in ceramic products, other household appliances, household appliances, etc., can solve the problems of pollution, soil damage, unsuitable for the growth of plants and crops, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

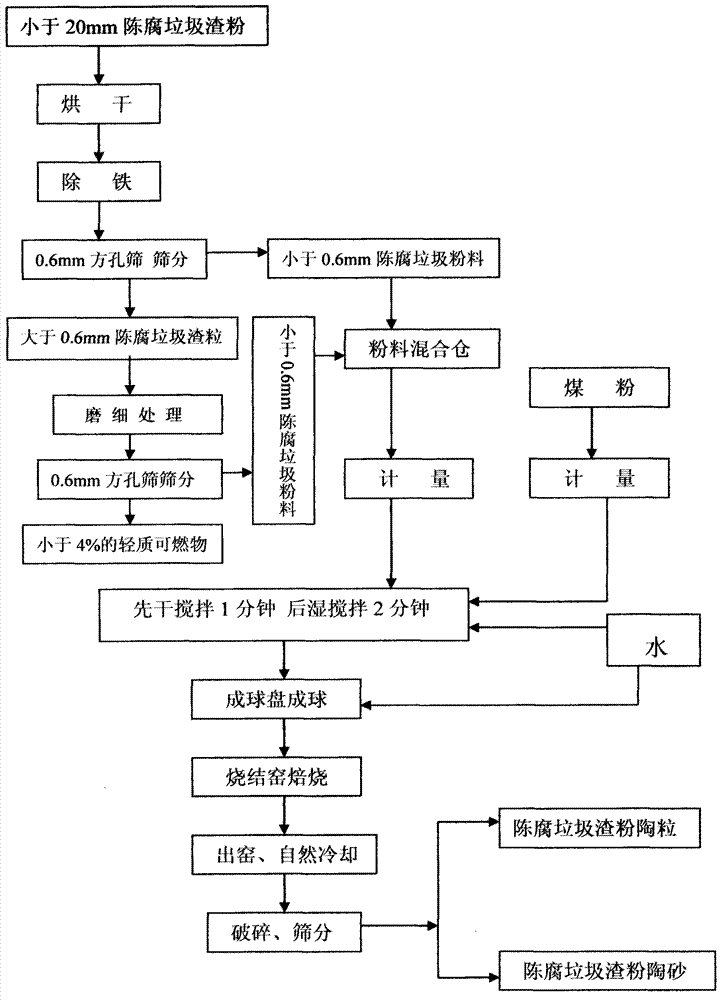

Method used

Image

Examples

Embodiment 1

[0025] Weight ratio:

[0026] 86% of stale garbage powder;

[0027] Coal powder 14%;

[0028] Manufacturing process:

[0029] 1. The stale garbage powder with particle size less than 20mm obtained after multiple sorting processes is dried first, and then iron is removed;

[0030] 2. The stale garbage powder after drying and iron removal is sieved with a 0.6mm square-hole sieve, and the bottom powder (about 52% of the total amount of stale garbage) is sieved with a 0.6mm square-hole sieve, as the production of ceramsite. The main raw material of the powder (the sand content in the powder accounts for about 49%);

[0031] 3. Screen the remaining slag particles (such as gravel, sand, brick, hard clod, broken glass, broken ceramics, broken cinder, broken plastic, etc.) (about 48%) (about 48%) by 0.6mm square hole sieve. , and then sieve with a 0.6mm square hole sieve, and sieve the bottom powder (about 96%) with a 0.6mm square hole sieve, as the main raw material for the produ...

Embodiment 2

[0040] Weight ratio:

[0041] 90% of stale garbage powder;

[0042] Coal powder 10%;

[0043] Manufacturing process:

[0044]1. Dry the stale garbage slag powder with a particle size of less than 20mm obtained after multiple sorting processes, and then remove iron;

[0045] 2. Sieve the stale garbage slag powder after drying and iron removal with a 0.6mm square hole sieve, and use the 0.6mm square hole sieve bottom powder (accounting for about 52% of the total amount of stale garbage) as the production of ceramsite The main raw material (the sand content in the powder accounts for about 49%);

[0046] 3. Sieve the 0.6mm square hole sieve residues (such as crushed stones, sand, bricks, hard soil, broken glass, broken ceramics, broken cinders, broken plastics, etc.) (accounting for about 48% of the total amount of stale garbage) %) to be ground, and then sieved with a 0.6mm square hole sieve, and the powder at the bottom of the 0.6mm square hole sieve (accounting for about 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com