Upper cutter shaft moving mechanism in edge trimmer

A technology of moving mechanism and trimming machine, which is applied in metal processing and other directions, can solve the problems of workpiece machining accuracy, gap and gap unevenness that affect the moving accuracy of the cutter shaft, and achieve the goal of improving production efficiency, ensuring detection accuracy, and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

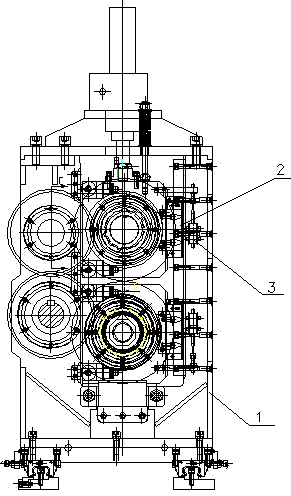

[0009] Further illustrate the present invention in conjunction with accompanying drawing and embodiment, as figure 1 As shown, the present invention arranges a linear guide rail 2 and a linear displacement sensor 3 on the trimming body 1, the linear guide rail 2 is fixed on the body 1, the fixed end of the linear displacement sensor 3 is fixed on the body 1, and the movable end of the linear displacement sensor 3 Installed on the guide rail slider; the linear displacement sensor adopts PY2-C-50 (GEFRAN).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com