Railway wagon brake pipe system joint body all-position welding device

A technology of railway wagons and welding devices, applied in welding equipment, auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of verticality and coaxiality between pipe fittings and joint bodies, difficulty in ensuring coaxiality, high labor intensity, and easy toppling of pipes, etc., to achieve The operation is convenient and reasonable for workers, the welding quality is high, and the effect of reducing unqualified products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

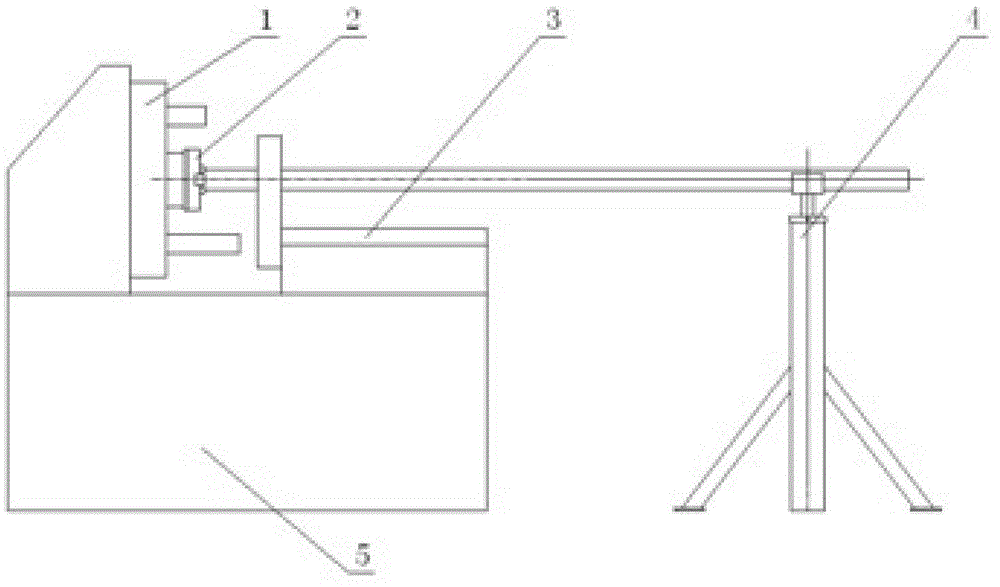

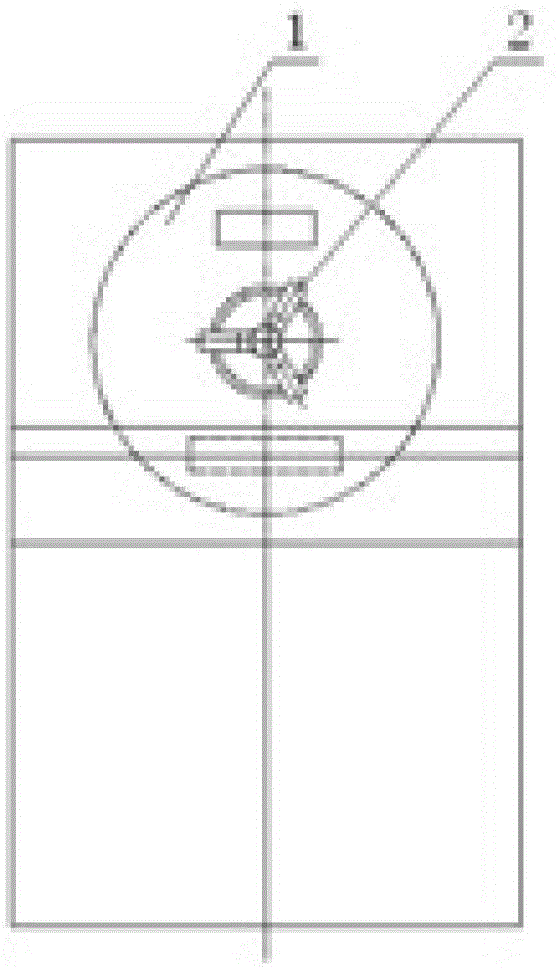

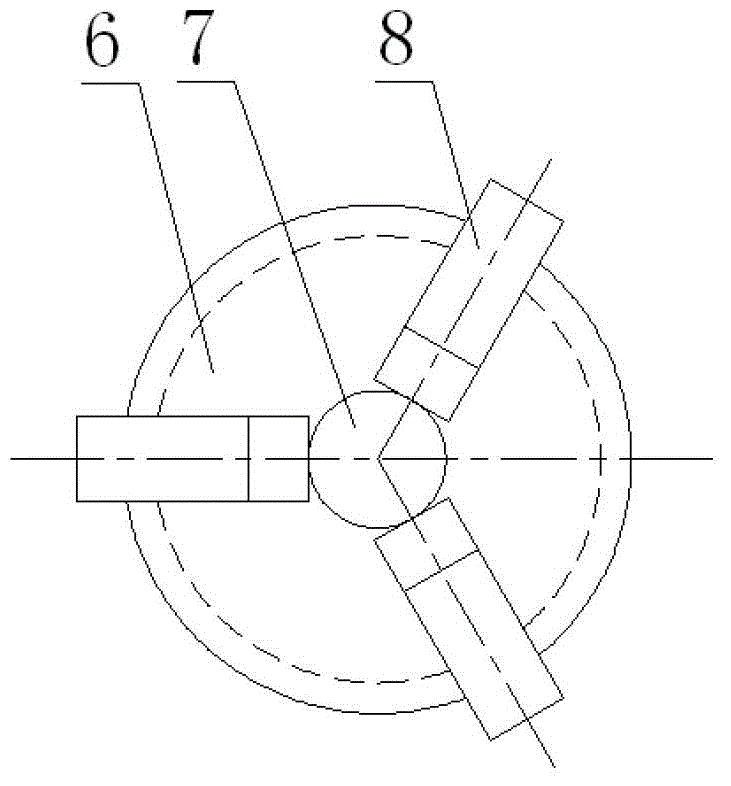

[0018] see Figure 1-Figure 7 , the present invention includes a support table 5, the key technology of which is to fixedly install a pneumatic three-jaw chuck 2 and a rotary table 1 driven by a DC motor on the support table 5, the rotary table 1 and the pneumatic three-jaw chuck 2 are coaxial and the rotary table 1 rotates relative to the pneumatic three-jaw chuck 2, the rotary table 1 is connected with the welding torch components, and the DC motor drives the rotary table to rotate so that the welding torch rotates relative to the fixed joint body (workpiece); the pneumatic three-jaw chuck includes a disc 6 and a uniformly distributed There are three movable jaws 8 on the disc 6, and the positioning ring 7 is located between the movable jaws 8 in the middle of the disc 6. The pneumatic three-jaw chuck uses the radial movement of three evenly distributed movable jaws. , to clamp and position the joint body. The pneumatic V-shaped clamping part 3 is installed at the position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com