Assembly Method of Inner and Outer Arc Frames of Slab Continuous Casting Sectors

A technology of slab continuous casting and outer arc frame, which is applied to the assembly of outer arc frame and the sector of slab continuous casting, can solve the problems of low welding process efficiency, long welding cycle, long working hours, etc., so as to improve welding work efficiency , Improve the precision of pre-welding assembly and simplify the effect of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

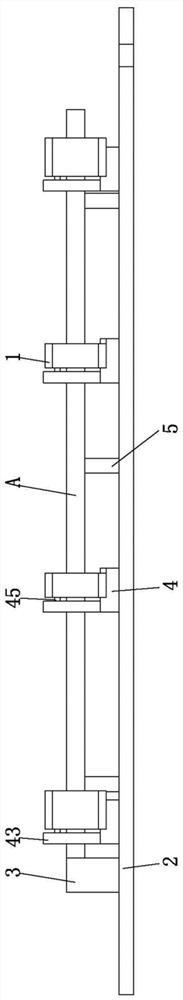

[0030] Combine below Figure 1 to Figure 9 The present invention will be described in detail.

[0031] The method for assembling the inner and outer arc frames of the slab continuous casting segment of the present invention comprises the following steps:

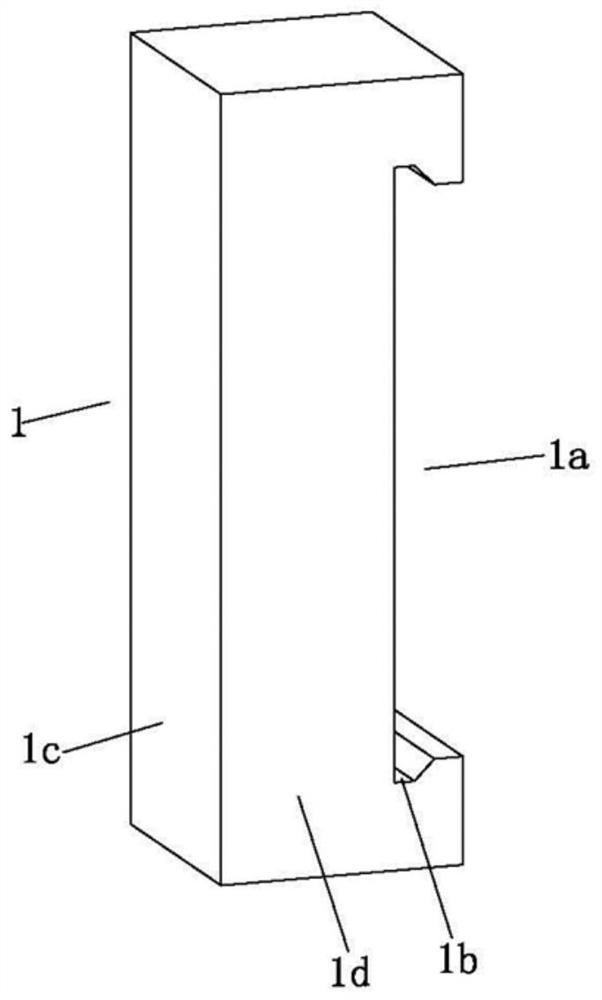

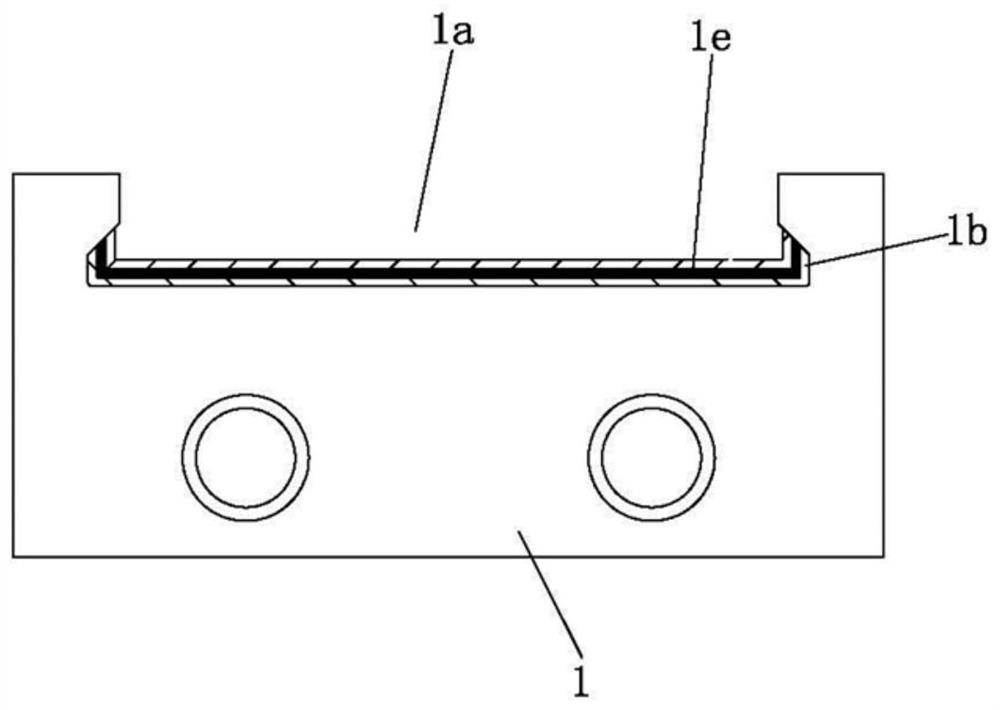

[0032] Step 1, machine the surfacing welding parts on the block 1, and use a robot to surfacing welding the block 1 in batches. Wherein the surfacing welding part is the groove 1a processed on the block 1, between the groove wall surface of the groove 1a and the bottom of the groove, there is a concave limit 1b recessed to the outside of the seat block 1, and the depth of the concave limit 1b is 3.2-4mm, the depth of the concave limit 1b is preferably 3.5mm, the height of the concave limit 1b is 6.5-7.5mm, and the height of the concave limit 1b is preferably 7mm. For surfacing welding from the groove bottom of the groove 1a, the surfacing welding wire is preferably made of ferritic stainless steel. The surfacing layer 1e ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com