A kind of inverted core assembly method

A technology of core assembly and lock core, which is applied in the direction of cores, casting molding equipment, casting molds, etc., can solve the problems of sand cores not being assembled in place, X-direction size deviation, Y-direction deviation, etc., so as to improve product qualification rate and reduce Dimensional variation and the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

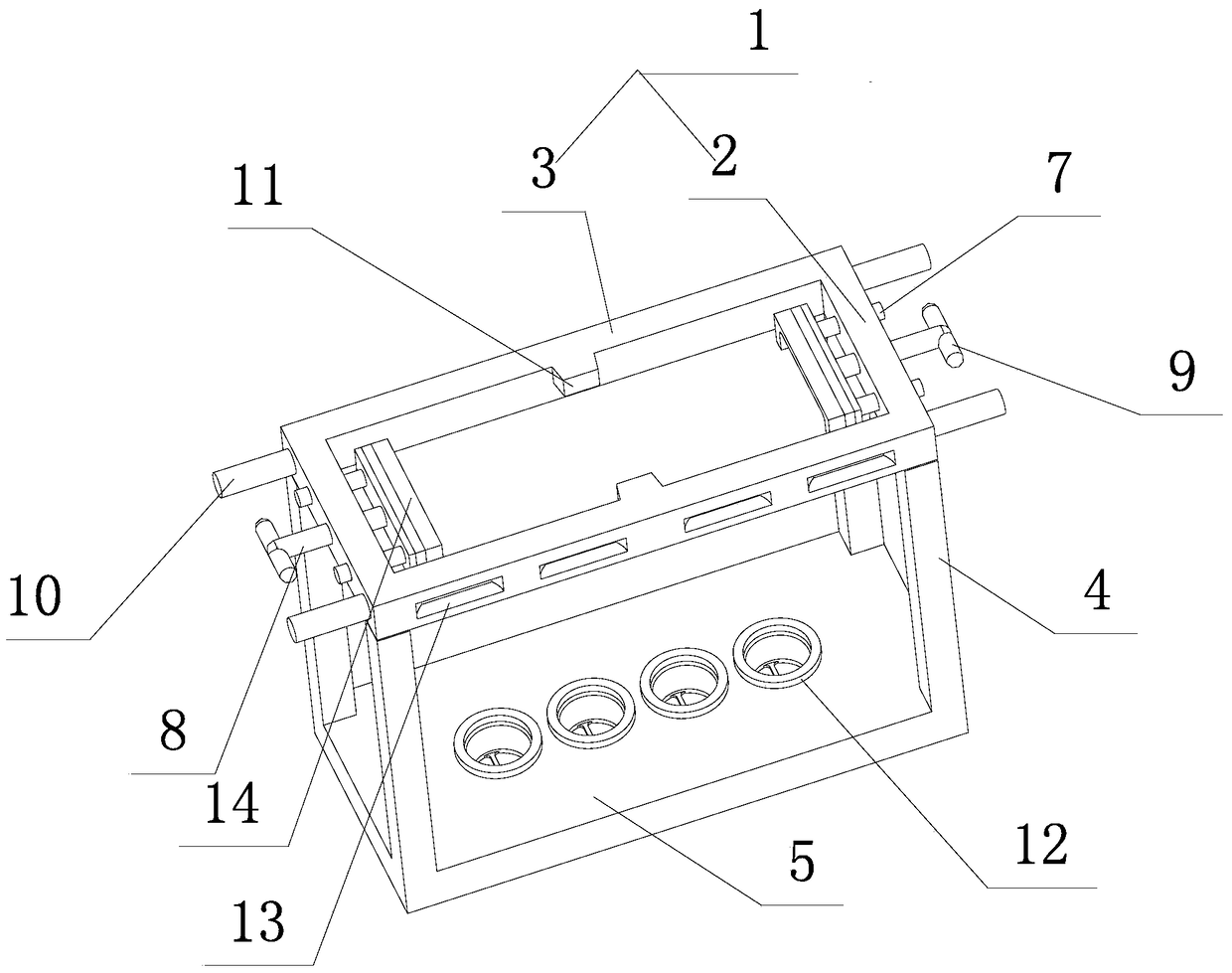

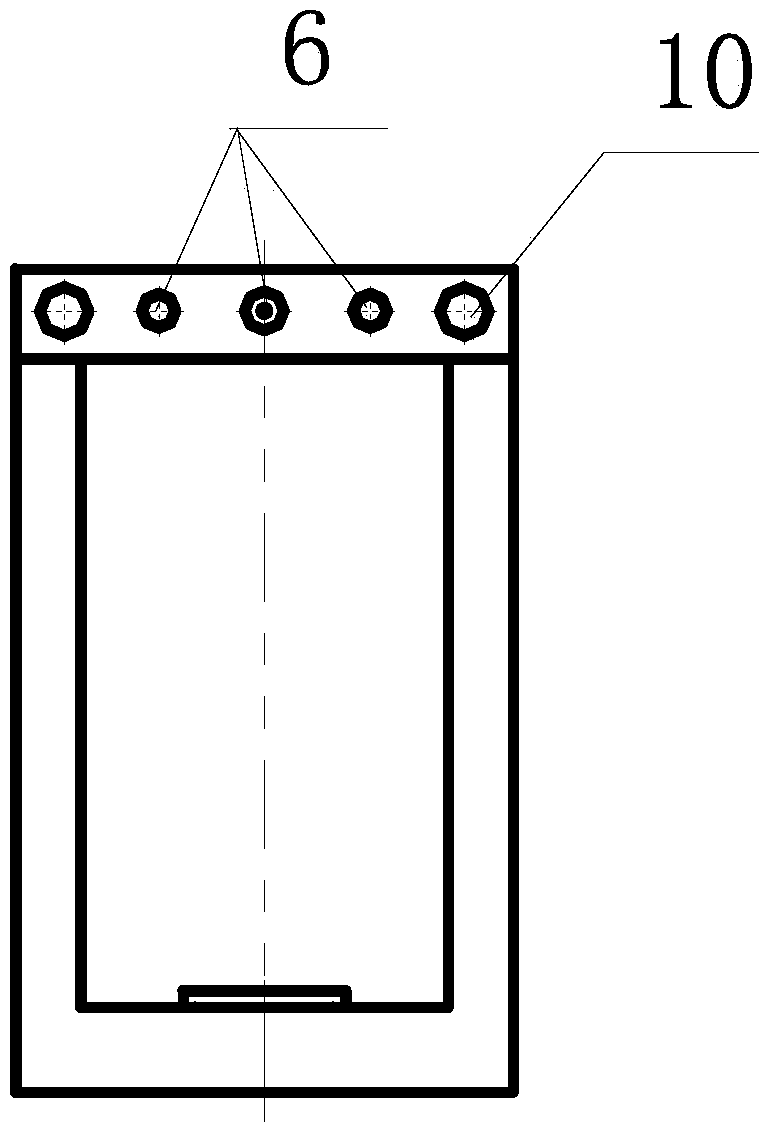

[0026] refer to figure 1 with figure 2 As shown, the entire structure is composed of an upper frame 1, a bracket 4 and a base 5. The upper frame 1 is composed of an adjustment end 2 and a limit end 3. The adjustment end 2 is provided with a handle 10 and an adjustment hole 6. The limit plate 14 passes through the The guide rod 7 and the adjusting screw rod 8 passing through the adjusting hole 6 are connected with the adjusting end 2, and the adjusting screw rod 8 is also provided with an adjusting handle 9; Limiting hole 12 with washer.

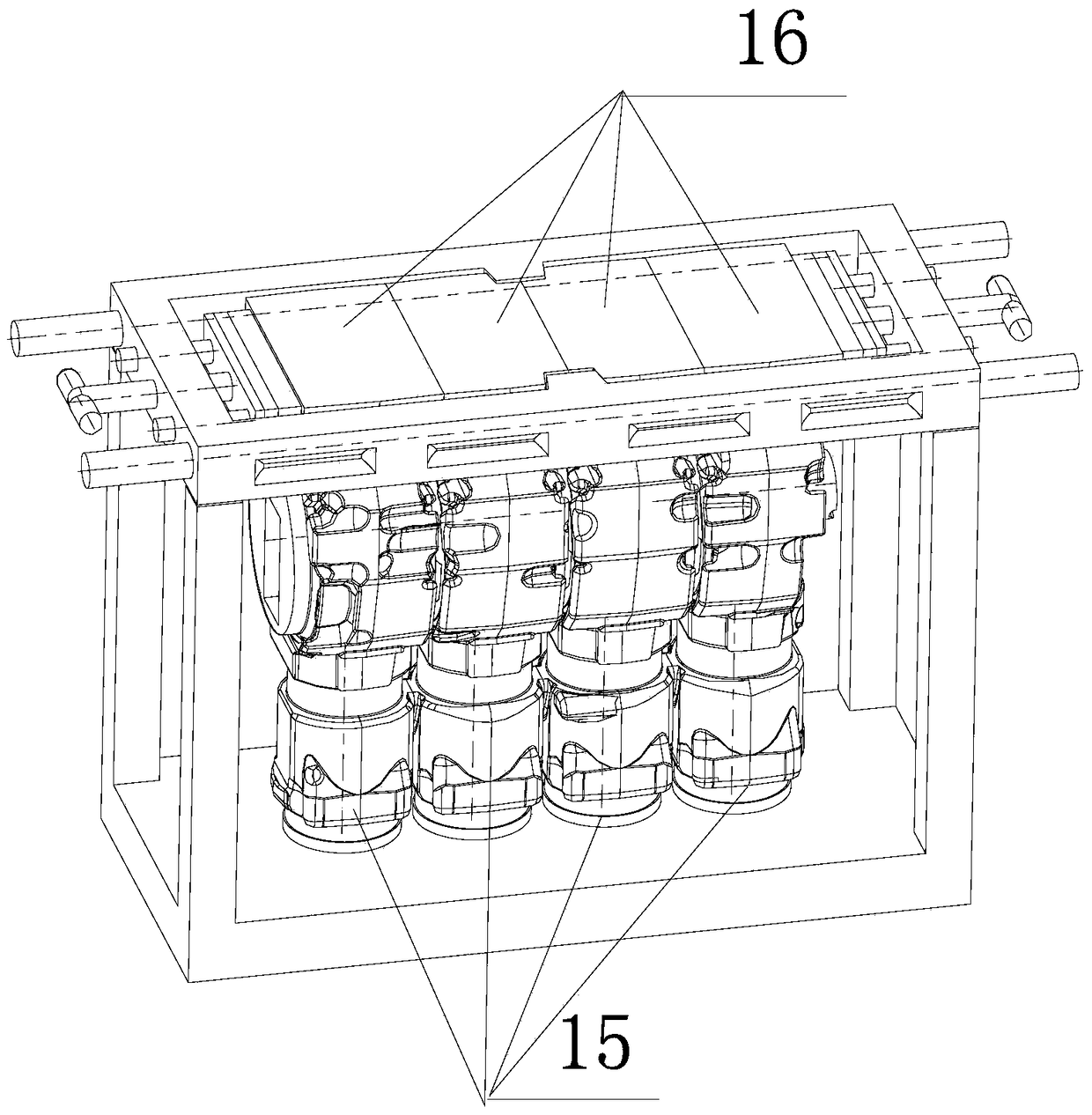

[0027] For the inverted core assembly method provided by the present invention, refer to image 3 shown, including the following steps

[0028] a. Lift the handle 10 to remove the upper frame 1 from the bracket 4, and place the lock cylinder 15 to be adapted in a vertical manner with the cylinder hole facing down and the crankshaft hole facing up in the limit hole 12 with the washer superior;

[0029] b. Then the upper frame 1 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com