Device for continuously adsorbing and desorbing organic waste gas by using active carbon

A technology of organic waste gas and activated carbon, which is applied in the direction of chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of difficult control and observation of the flow state, easy clogging of adsorbents, and difficult processing, so as to ensure continuity and The effect of stability, good working environment and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

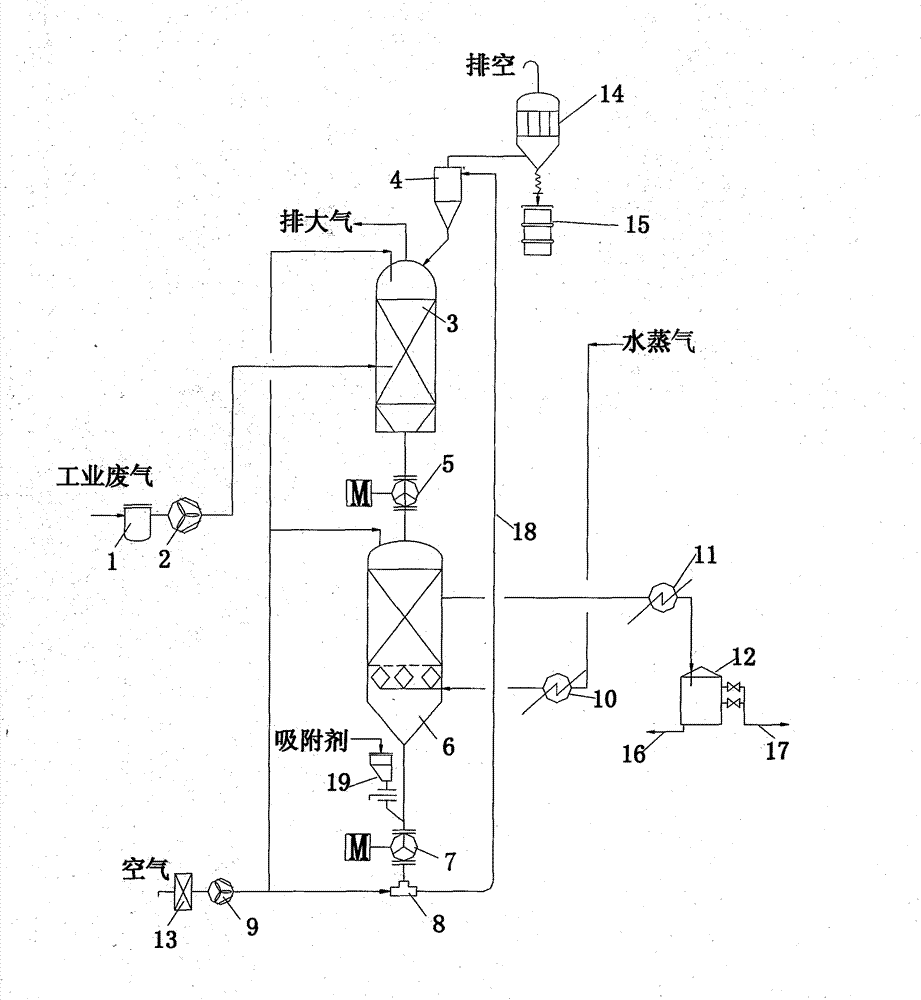

[0042]After the waste water in polycarbonate production flows into the coalescer, the glue liquid is returned to the polycarbonate production, the waste water enters the separation tank for static separation, the upper waste water is pumped into the distillation tower for distillation with low pressure steam, and most of the dichloromethane steam is condensed After returning to polycarbonate production, the uncondensed gas at the top of the distillation tower contains a trace amount of methylene chloride, generally 500-1000 ppm. figure 1 Shown is a device for continuous adsorption and desorption of organic waste gases by activated carbon. The operation steps are as follows:

[0043] a) After the organic waste gas discharged from the factory is removed by the first filter (1) to remove the polycarbonate fragments, it is pressurized by the first fan (2) and sent to the adsorption tower (3) for adsorption. The adsorbent adopts the dense phase pneumatic conveying method from The ...

Embodiment 2

[0049] In the toluene nitration process, the external drainage steam contains a trace amount of toluene, generally 500-1000ppm. figure 1 Shown is a device for continuous adsorption and desorption of organic waste gases by activated carbon. The operation steps are as follows:

[0050] a) After the organic waste gas discharged from the factory is removed from the solid particles by the first filter (1), it is pressurized by the first fan (2) and sent to the adsorption tower (3) for adsorption, and the adsorbent adopts the dense phase pneumatic conveying method to enter from the upper part In the adsorption tower (3), the gas inlet pressure is controlled at 0.15-0.30MPa, the gas velocity is controlled at 3-8m / s, and the mixing ratio is 100-300;

[0051] b) The industrial waste gas containing toluene solvent enters from the bottom inlet of the adsorption tower (3), the activated carbon moves down the moving bed, and the waste gas freely passes through the activated carbon for gas...

Embodiment 3

[0055] There is a trace amount of xylene in the drainage vapor from the xylene nitration process, generally 500 to 1000 ppm. figure 1 Shown is a device for continuous adsorption and desorption of organic waste gases by activated carbon. The operation steps are as follows:

[0056] a) After the organic waste gas discharged from the factory is removed from the solid particles by the first filter (1), it is pressurized by the first fan (2) and sent to the adsorption tower (3) for adsorption, and the adsorbent adopts the dense phase pneumatic conveying method to enter from the upper part In the adsorption tower (3), the gas inlet pressure is controlled at 0.15-0.30MPa, the gas velocity is controlled at 3-8m / s, and the mixing ratio is 100-300;

[0057] b) The industrial waste gas containing xylene solvent enters from the bottom inlet of the adsorption tower (3), the activated carbon moves down the moving bed, and the waste gas freely passes through the activated carbon with low re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com