Environmental-friendly combustion furnace

An incinerator and environmental protection technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of low thermal efficiency, large power consumption, large equipment investment, etc. The effect of low smoke temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

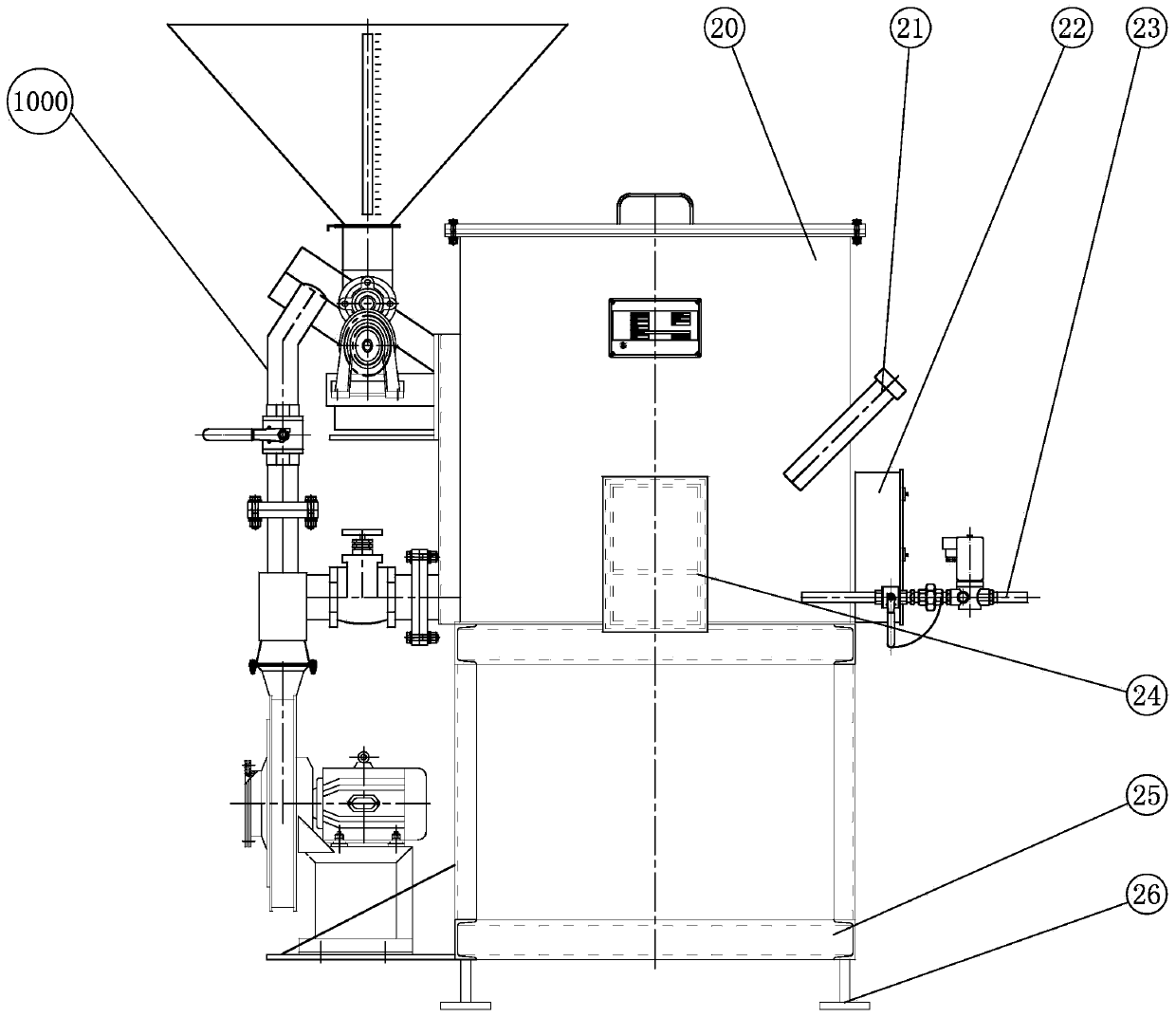

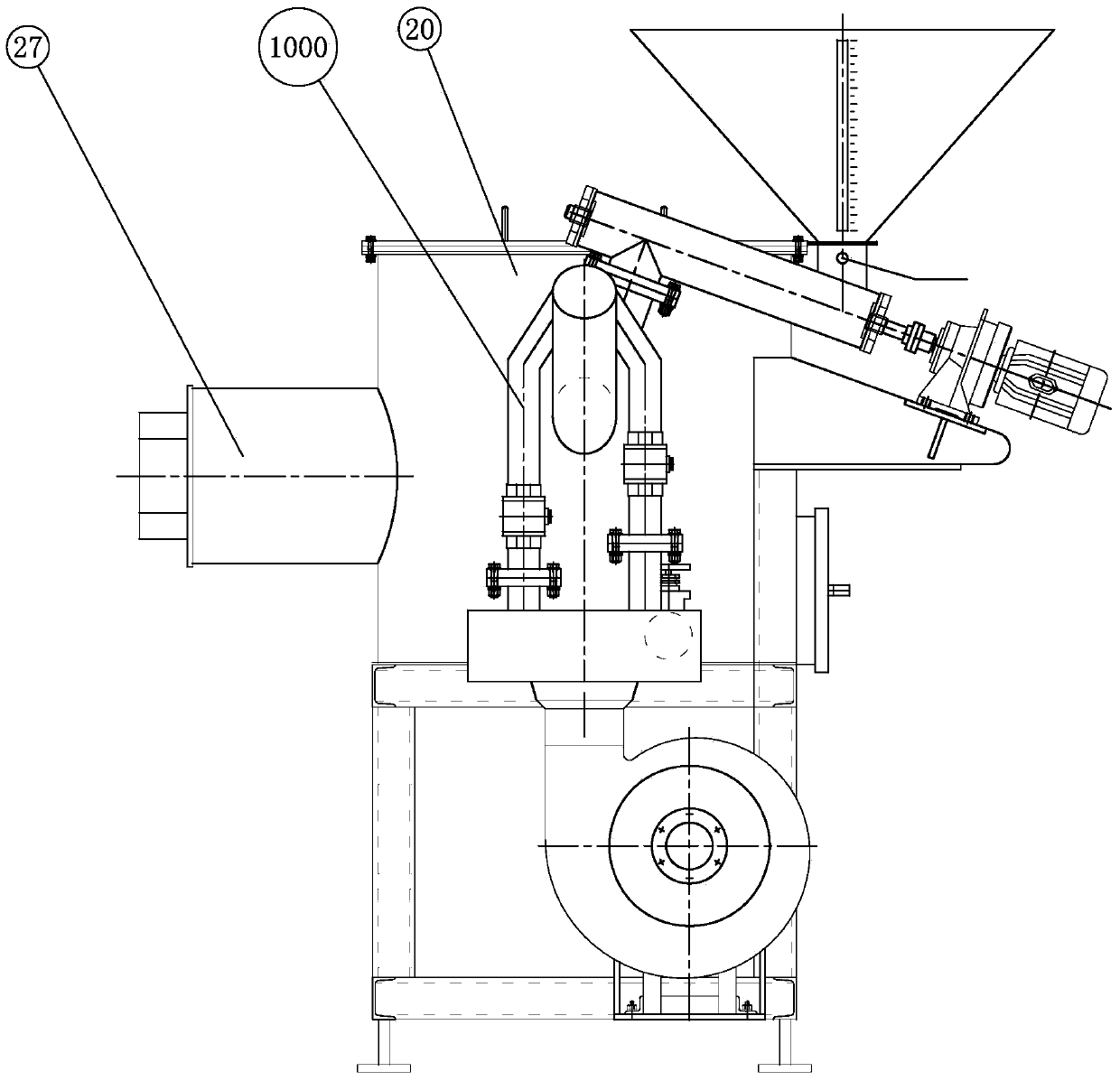

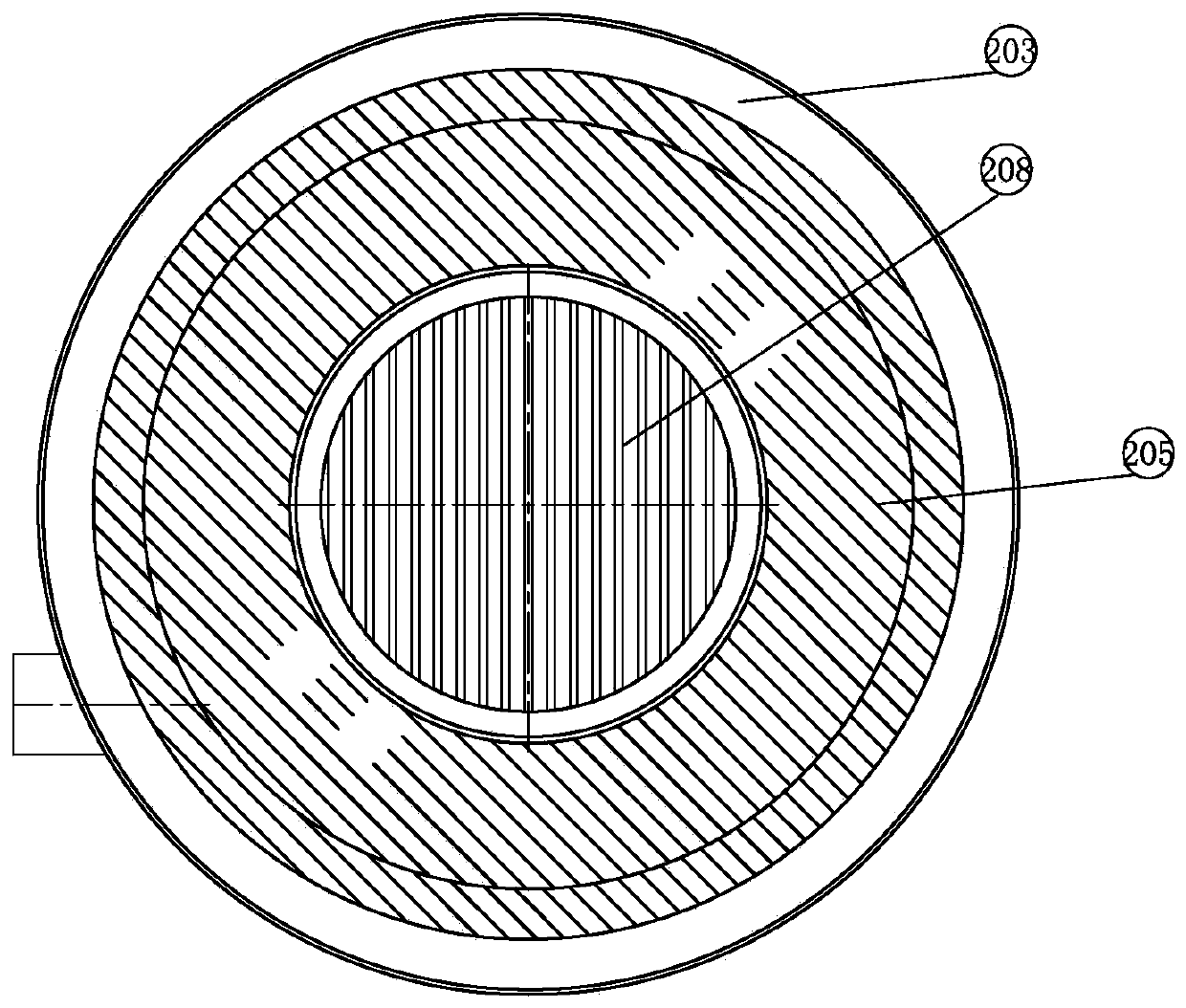

[0021] Embodiment: First, put the biomass fuel into the feeding device 16, the biomass fuel enters the barrel 4 through the feed port 5, starts the motor 14, and after decelerating through the cycloidal pin wheel reducer 13, the power of the motor 14 passes through The coupling 12 is transmitted to the feeding shaft 10, and with the rotation of the feeding shaft 10, the rotation of the screw blade 11 is driven, and the biomass fuel is sent to the upper end of the barrel 4, and the biomass fuel is crushed by the crushing knife 3 and then blocked in the The baffle plate 1 is then blown into the discharge port 18 through the blanking port 9 through the air flow of the air supply pipe 17, and enters the combustion chamber 20. After the ignition device 23 is ignited, it can be used normally, and the furnace can be observed through the observation hole 21. In the internal combustion state, the controller 22 controls the fan 15 according to the actual temperature requirement of the bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com