Horizontal flushing water tube type central back-firing boiler

A water pipe type, horizontal technology, applied in the direction of water heaters, lighting and heating equipment, fluid heaters, etc., can solve the problem of low surface heat transfer coefficient, high heat resistance and sealing performance requirements of the smoke transfer chamber, and large heat loss, etc. problem, to achieve the effect of large heat transfer temperature difference, volume reduction, and area reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

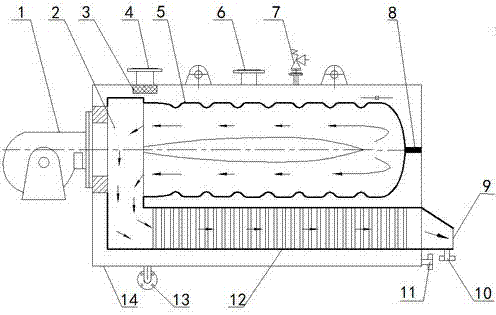

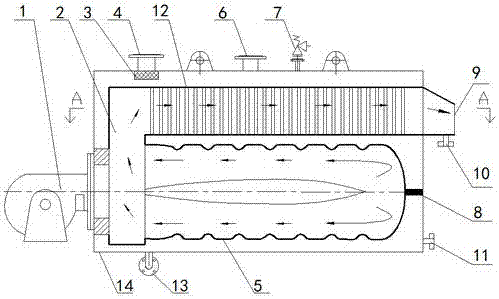

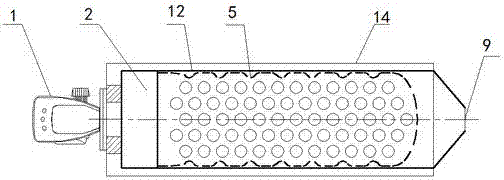

[0012] The following will further describe the specific implementation of the horizontal flushing water tube type central back-firing boiler in conjunction with the accompanying drawings.

[0013] The main components of the horizontal flushing water tube central recovery boiler include burners, shells, furnaces, smoke transfer chambers and box heat exchangers. The boiler shell is a cuboid, which is formed by vertically butting and welding six flat plates; the flue gas heat exchange surface of the boiler includes a furnace furnace, a smoke transfer chamber and a box-type heat exchanger, and an upper furnace tank and a lower box-type heat exchanger are used. Arranged in the same way, the furnace liner, box-type heat exchanger and the smoke transfer chamber are connected by welding, the furnace liner, the smoke transfer room and the box-type heat exchanger are all immersed in the furnace water, and the flue gas heat exchange surface is a fully wet back structure.

[0014] The fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com