Mobile phase degassing processing device in simulated moving bed separation technology

A technology of simulating moving bed and separation technology, which is applied in the field of mobile phase degassing treatment devices, can solve the problems of changing the running route of the material and liquid, affecting the separation effect of the system, reducing the service life of the resin, etc. The effect of flashing area and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

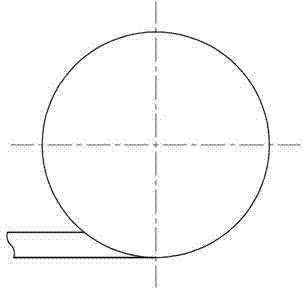

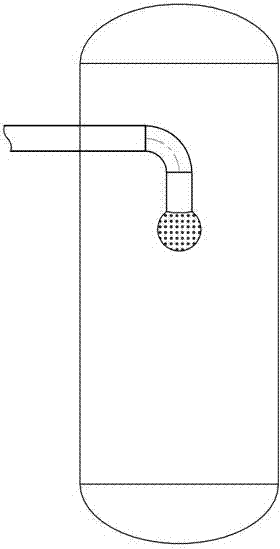

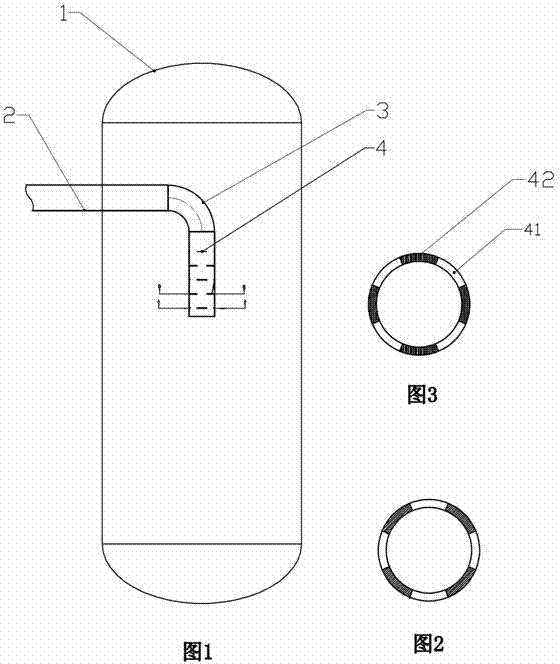

[0016] Such as figure 1 , figure 2 , image 3 . The mobile phase degassing treatment device in the simulated moving bed separation technology includes a flash tank 1, and the feed pipe 2 is connected to the nozzle located in the upper center of the flash tank 1 through an elbow 3. The nozzle is a columnar multi-layer film Nozzle 4, the feed liquid is sprayed on the inner wall of the container of the flash degassing device in the form of a film. The laminar nozzle 4 is provided with laminar slits 41 distributed in the horizontal direction along the cylindrical surface, and the adjacent laminar slits 41 in the up and down direction are dislocated, and the adjacent laminar slits 41 are formed by the laminar nozzle walls 42 .

[0017] There are four film slits 41 distributed along the circumference of the cylinder, and the slits of each film are of the same size, and the distance between adjacent film slits in the horizontal direction is equal to the circumferential length o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com