Method for Reaction Recycle Gas Decarbonization Tail Gas Emission Reaching Environmental Protection Index

A technology for decarbonizing tail gas and circulating gas, which is applied in separation methods, chemical instruments and methods, and air quality improvement, and can solve problems such as unbearable for enterprises and unreasonable economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

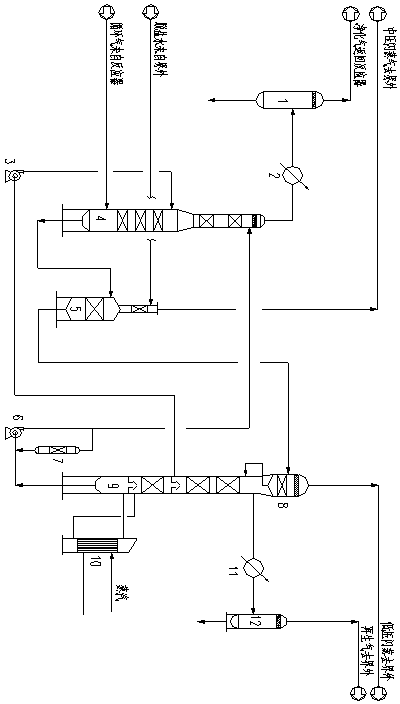

Image

Examples

Embodiment 1

[0026] A coal-to-liquids unit with a scale of 1 million tons / year, the Fischer-Tropsch synthesis reaction cycle gas removes the by-reaction product CO 2 The decarburization unit adopts potassium carbonate decarburization process. The pressure is 1.8 MPa (absolute pressure) and the circulating gas enters the decarburization system, and the circulating gas volume is 375650.00 Nm 3 / h, where CO 2 The concentration is 15.795 mol%, the concentration of hydrocarbons is 22.966 mol%, and the concentration of alcohols, acids and ketones is 1.033 mol%. Absorb CO 2The content of non-methane hydrocarbons in the final rich liquid is 74.93kg / h, and the content of alcohols, acids and ketones is 1236.81 kg / h. After passing through the 1.2 MPa (absolute pressure) rich liquid medium-pressure flash tank, the content of non-methane hydrocarbons in the flashed rich liquid is reduced to 37.5 kg / h, and the content of alcohols, acids and ketones is reduced to 234.59 kg / h. After the flash gas is c...

Embodiment 2

[0030] For a 200,000-ton / year ethylene-to-ethylene oxide plant, the side reaction product CO is removed from the cycle gas of the oxidation synthesis reaction 2 The decarburization unit adopts potassium carbonate decarburization process. The pressure is 2.38 MPa (absolute pressure). The circulating gas enters the decarbonization system, and the circulating gas volume is 668822.04 kg / h, of which CO 2 Concentration 1.44 mol%, ethylene concentration 28.61 mol%, O 2 Concentration 5.68 mol%, the rest is CH 4 、C 2 h 6 , N 2 , Ar and a small amount of water vapor and MEG. Absorb CO 2 The content of non-methane hydrocarbons in the rich liquid after medium pressure flashing is 322.11kg / h. After passing through the 1.2 MPa (absolute pressure) rich liquid medium-pressure flash tank, the content of non-methane hydrocarbons in the rich liquid after medium-pressure flashing is reduced to 87.5kg / h . After the flash gas is cooled and separated in the washing section at the top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com