Orchard trencher

A ditching machine and orchard technology, applied in the direction of digging/covering ditches, applications, planting methods, etc., can solve the problem that the mechanical transmission cannot adapt to the harsh environment of load changes, it is difficult to adapt to the ditching operation environment of sloping orchards, and the engine cannot be fully utilized Power and other issues, to achieve the effect of improving economy and power, low noise, and smooth speed change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

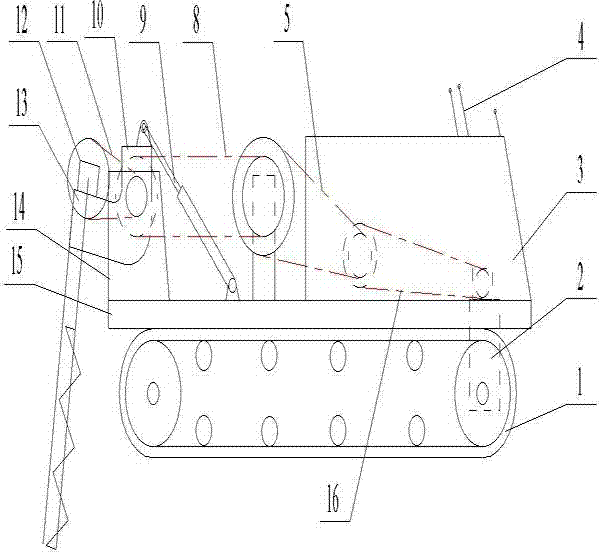

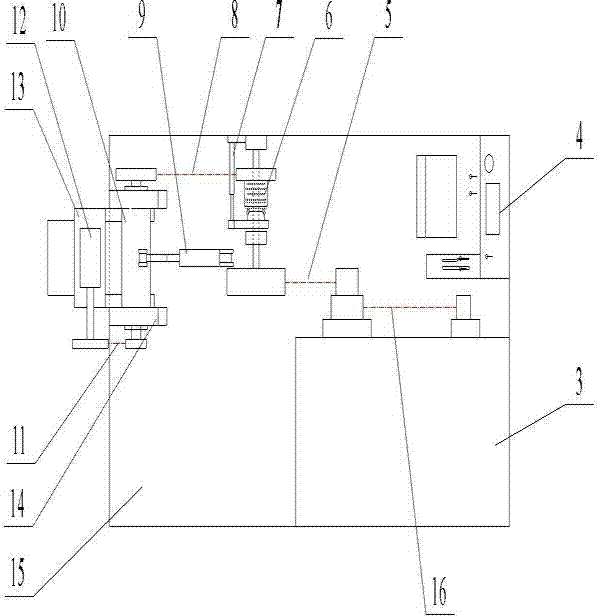

[0022] like figure 1 , figure 2 Shown, the present invention mainly is made up of frame, motor, walking system, control system, transmission system, ditching device, swing support, fixed support, lifting oil cylinder and gearbox.

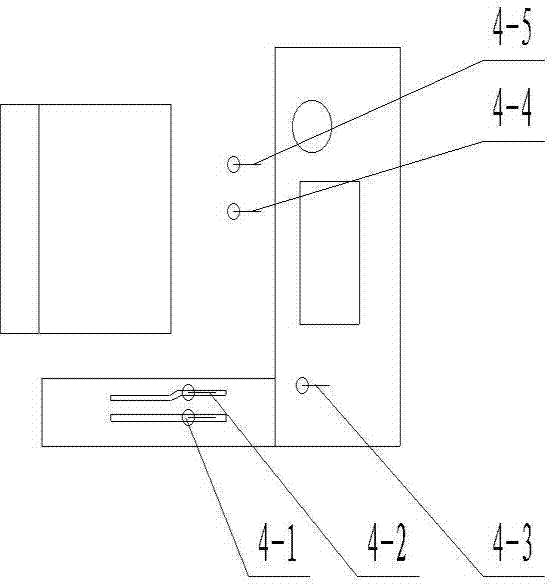

[0023] Control system 4, engine 3, transmission system, fixed support 14 are installed on the frame top, and engine 3 is positioned at the frame front. The ditching device 13 adopts an oblique swing suspension type and is located at the rear of the frame. The ditching device 13 is connected with the gearbox 12 and installed on the swing bracket 10. The swing bracket 10 is connected with the fixed bracket 14 through a hinge. The ditching device 13 It forms a certain angle of inclination with the ground.

[0024] The power of the engine 3 is transmitted to the ditching device 13 through the belt drive I5, the clutch 6, the chain drive I8, the chain drive II11, and the gearbox 12. The clutch oil cylinder 7 controls the opening and closing action of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com