Production system and production method for continuously producing ethanol by ethyl acetate through using hydrogenation

A production system, ethyl acetate technology, applied in chemical instruments and methods, climate sustainability, sustainable manufacturing/processing, etc., can solve the problems of lack of production equipment and production systems, restrictions on industrial scale, and high energy consumption of ethanol, To achieve the effect of reducing energy consumption, reducing usage, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

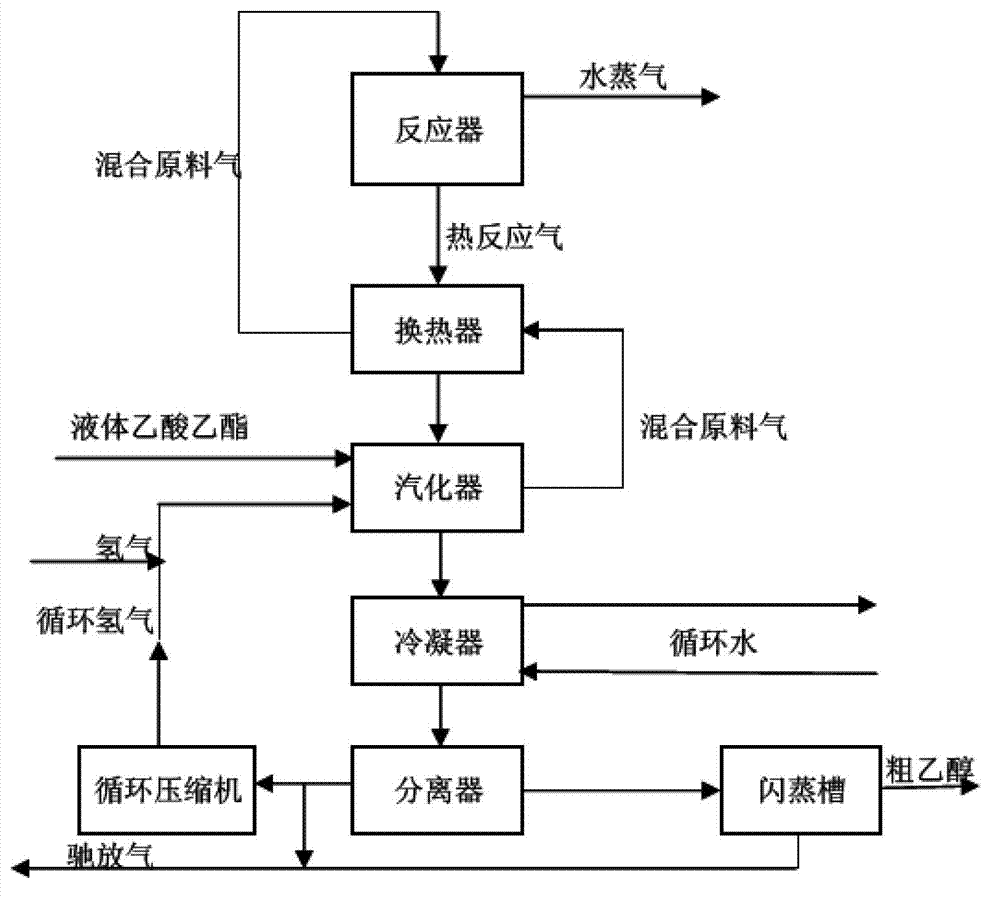

[0045] like figure 1 As shown, the production system provided by the present invention includes a vaporizer, a heat exchanger, a reactor, a condenser and a separator.

[0046] Among them, the inlet of the vaporizer tube is the inlet of the raw material, the outlet of the vaporizer tube is connected with the inlet of the heat exchanger tube, the outlet of the heat exchanger tube is connected with the inlet of the reactor, and the outlet of the reactor is connected with the heat exchanger shell The inlet of the shell side of the heat exchanger is connected, the outlet of the shell side of the heat exchanger is connected with the inlet of the shell side of the evaporator, and the outlet of the shell side of the evaporator is connected with the condenser and the separator in turn.

[0047] The production system may also include a circulation compressor and a flash tank, which are respectively connected with the separator.

[0048] The circulating compressor is connected with the ...

Embodiment 2

[0058] Embodiment 2 produces the production process of 200,000 tons of ethanol per year

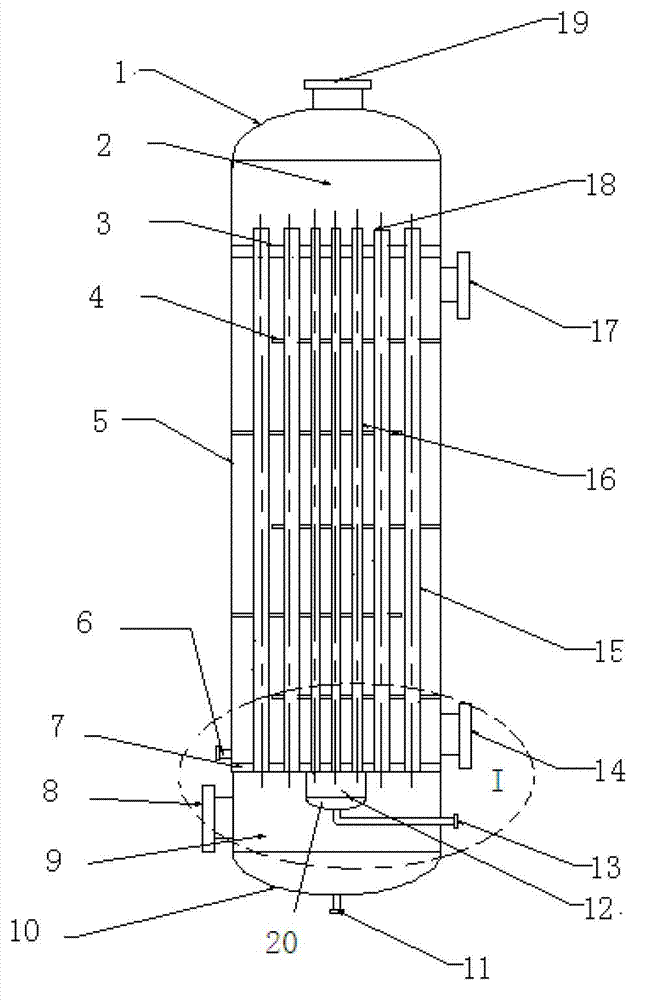

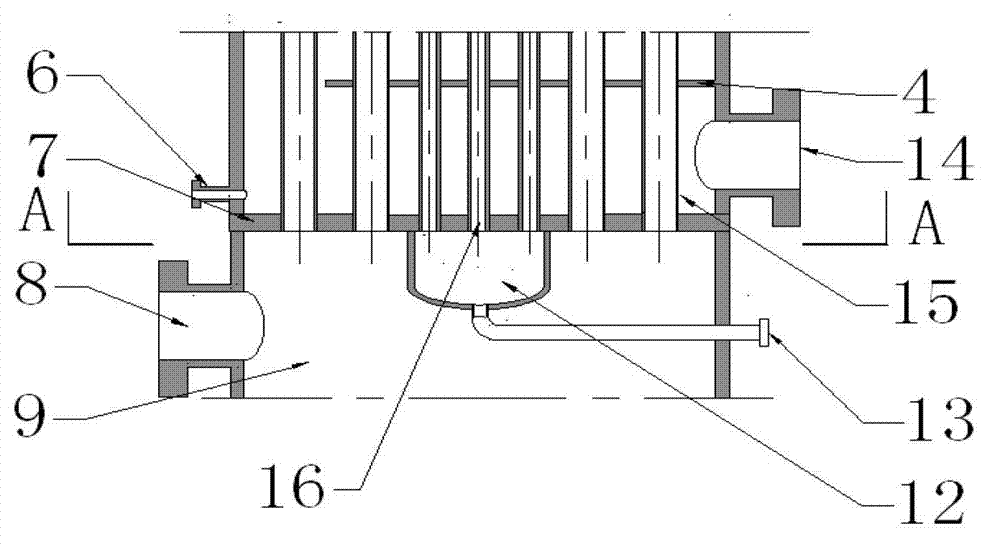

[0059] With a supply flow rate of 26 tons / hour, the liquid ethyl acetate raw material enters the preheating tube bundle 16 of the vaporizer from the liquid raw material inlet 13 of the vaporizer through the sub-tube box 12, flows upward in the preheating tube bundle 16, and is covered by the shell during the flow process. The hot reaction gas in the process is preheated to near the saturation temperature, and then uniformly flows into the evaporating tube bundle 15 through the liquid distributor arranged above the upper tube sheet 3, and forms a film in the evaporating tube bundle 15 and flows downward by gravity.

[0060] Cool raw hydrogen at 266000Nm 3 The supply flow rate of / h enters the evaporator tube bundle 15 of the evaporator from the cold raw material gas inlet 8 at the bottom of the vaporizer through the lower tube box, flows upward in the evaporator tube bundle 15, and contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com