Treatment method for removing arsenic and COD in wastewater in gallium arsenide wafer production treatment simultaneously

A technology for gallium arsenide wafers and processing wastewater, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., and can solve the problem of not being able to remove arsenic and COD from gallium arsenide wafers at the same time. , to achieve the effect of high operation stability and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

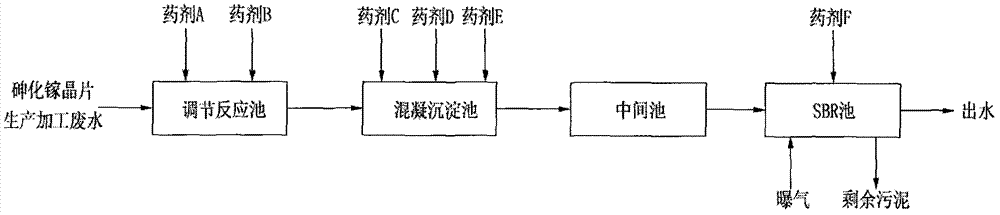

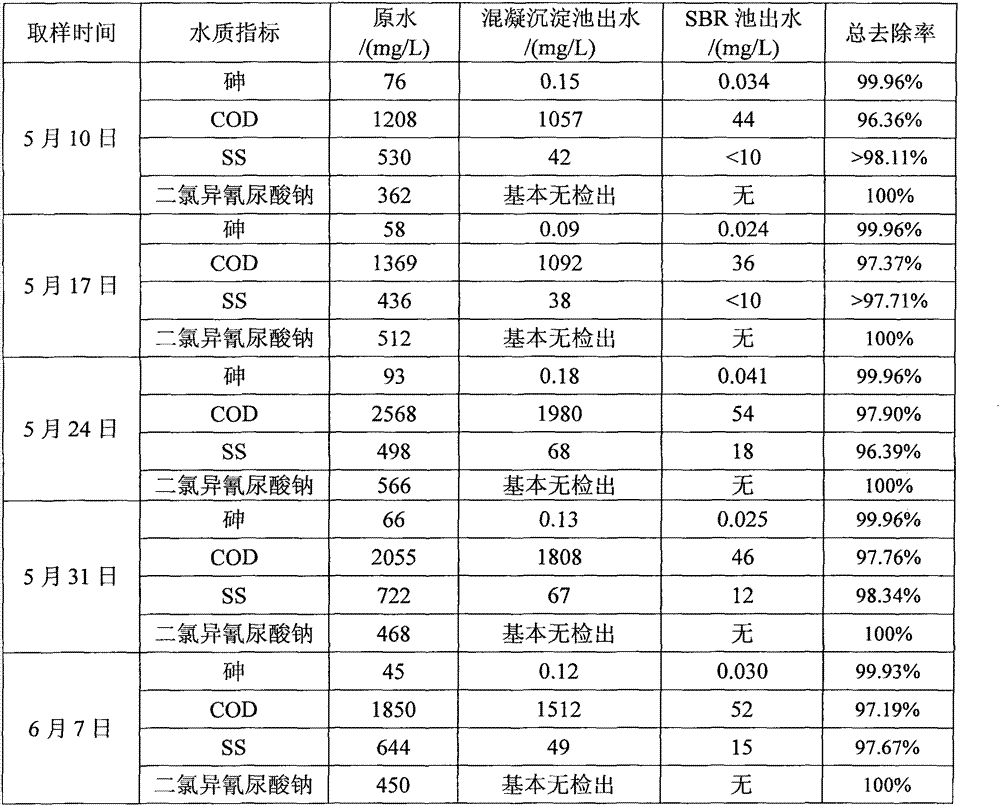

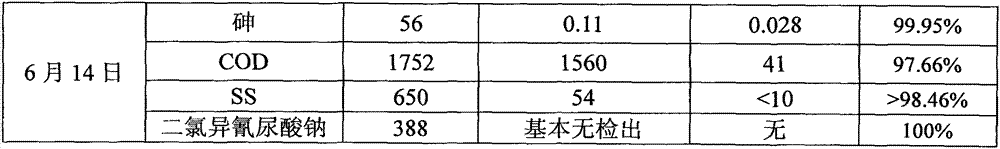

[0022] 1) The incoming water flow rate is 10m 3 / h, keep at least 10m in the adjustment reaction pool by controlling the minimum liquid level 3 Reaction solution, (that is, the hydraulic retention time is not less than 1h); quantitatively add ferrous sulfate and hydrogen peroxide, so that the concentration of ferrous ions in the reaction solution is 150mg / L, and the concentration of hydrogen peroxide is 560mg / L. The pH value of the reaction solution is between 2.7 and 2.8, just in the optimum pH reaction range, and no additional pH adjustment is required. The main purpose of this unit is to apply fenton reaction to remove sodium dichloroisocyanurate in raw water and partially remove COD in raw water.

[0023] 2) Lift the wastewater from the adjustment reaction tank to the coagulation sedimentation tank with a pump, and carry out the sequence batch coagulation sedimentation reaction. The process is to inflow water and add ferric chloride to make the final reaction liquid iron ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com