Anti-skidding device on tail pulley of plate chain bucket elevator and anti-skidding method

A bucket elevator, anti-skid technology, applied in the field of conveying machinery, can solve the problems of frequent up and down movement, affecting the production of the cement mill system, etc., to achieve the effect of reducing operating power consumption, increasing cement output, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with specific example the present invention is described in further detail:

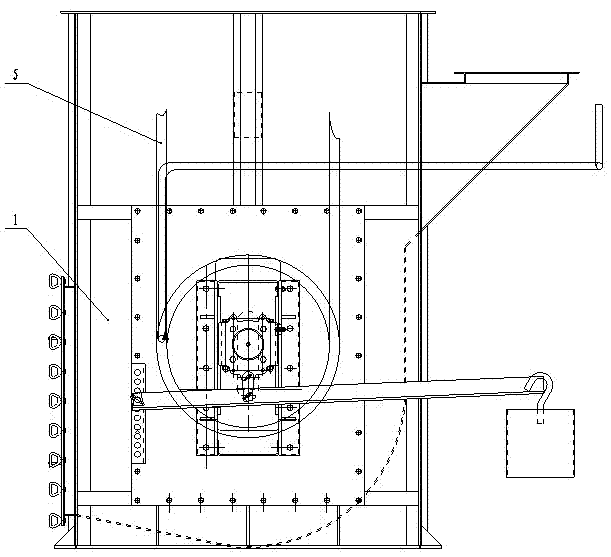

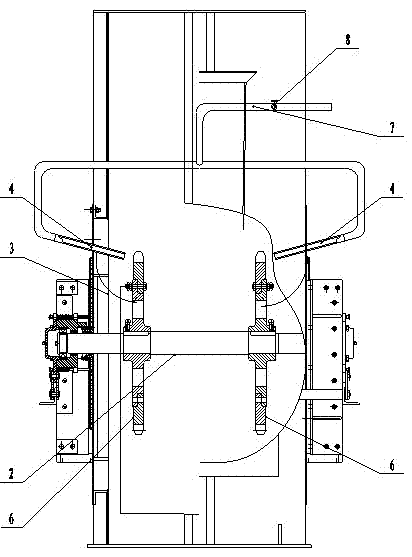

[0015] like figure 1 and figure 2 As shown, a compressed gas pipeline is included, and the pipeline is provided with a main air pipe 7, which communicates with the air distribution pipe 9 extending to both sides, the two air outlet ends of the air distribution pipe 9 are bent, and the nozzle 4 at each air outlet end is inclined Set, the air intake end of total air pipe 7 is provided with air valve 8.

[0016] The method for anti-slipping of the plate chain bucket elevator chain at the tail wheel of the present invention, its steps are as follows:

[0017] A. Lead the compressed gas with a pressure of 0.8MPa to the bottom of the plate chain bucket elevator 1 as a blowing gas source;

[0018] B. An anti-skid device is provided outside the housing 3 at the bottom of the plate chain bucket elevator. The air distribution pipe 9 of the anti-skid device straddles the two side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com