Quick blow-drying device for transfer printing marks of shaping rubber pipe products

A technology for setting glue and products, applied in the general parts of printing machinery, printing, printing machines and other directions, can solve the problems of low production efficiency, low efficiency and incomplete marking of rubber hoses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

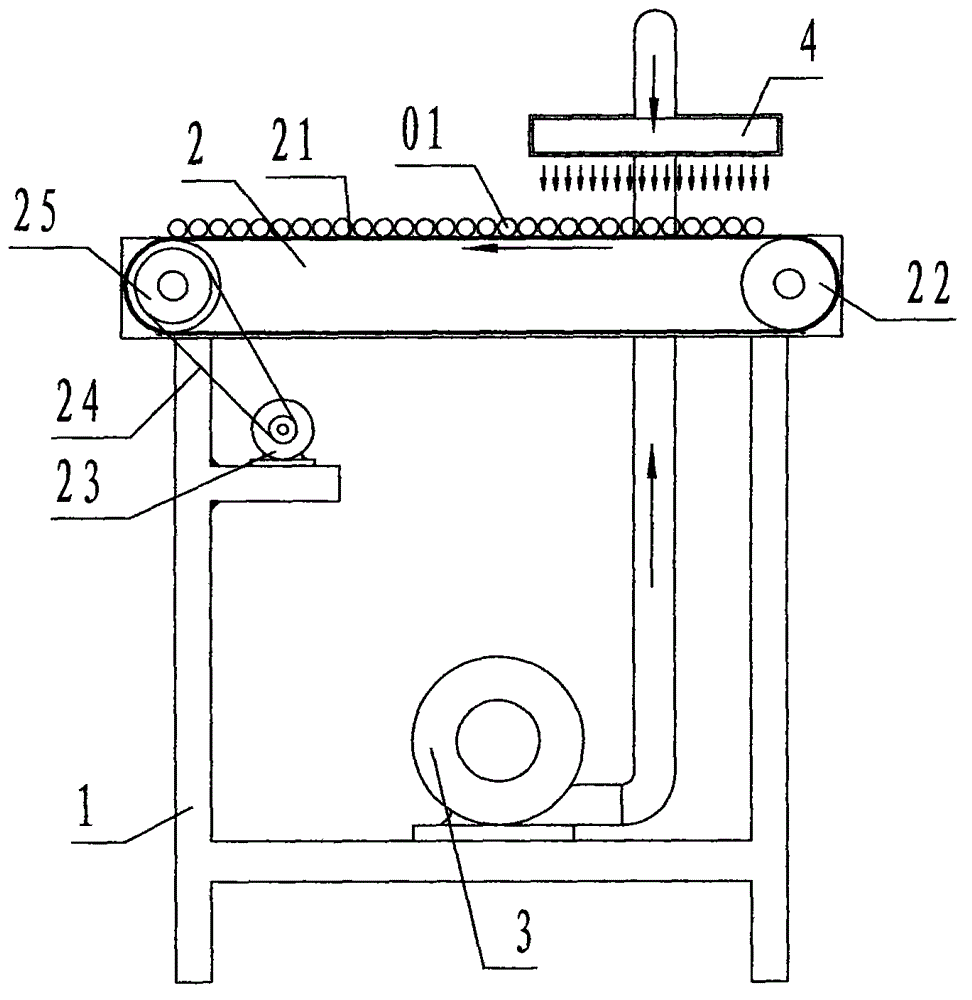

[0013] refer to figure 1 , a fast drying device for pad printing marks of shaped rubber hose products according to the present invention, comprising a bracket 1, a belt conveyor 2, a blower 3, and a blowing pipe 4, wherein: the bracket 1 is a rectangular frame member welded by angle steel , the top of the support 1 is provided with a belt conveyor 2 made of a conveyor belt 21, a shaft roller 22, a motor 23, a transmission belt 24, and a pulley 25, wherein the two shaft rollers 22 rotate respectively on the left and right sides connected to the support 1. Side, the conveyor belt 21 is stretched around the outer edge of the two shaft rollers 22, the motor 23 is fixedly connected to the middle part of the bracket 1, and the motor 23 passes through the pulley 25 through the transmission belt 24 and the shaft roller 22 connections;

[0014] The blowing pipe 4 is a closed, hollow, rectangular thin-walled steel member, and the blowing pipe 4 is provided with some through holes unifo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com