A kind of recyclable reinforced foam sheet packaging material and preparation method thereof

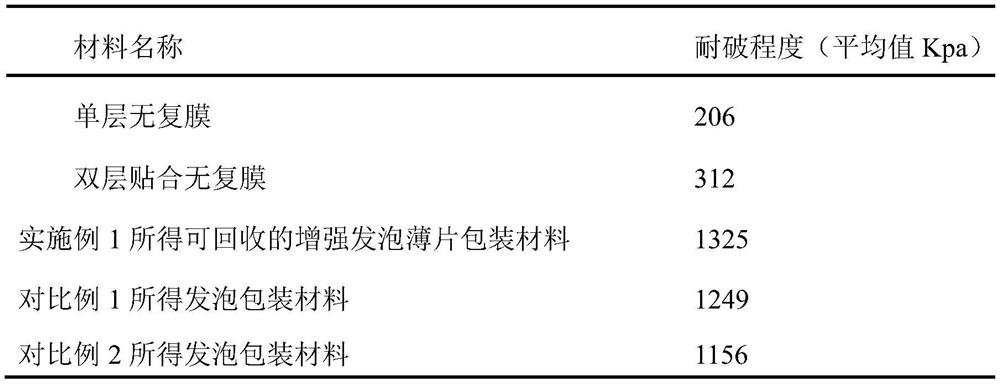

A packaging material and sheet technology, applied in the field of enhanced foam sheet packaging materials and its preparation, can solve the problems of corrugated cardboard, such as easy aging, heavy packing box, easy breakdown, etc., to increase mechanical strength, compressive capacity, and solvent resistance Excellent performance, the effect of improving the overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

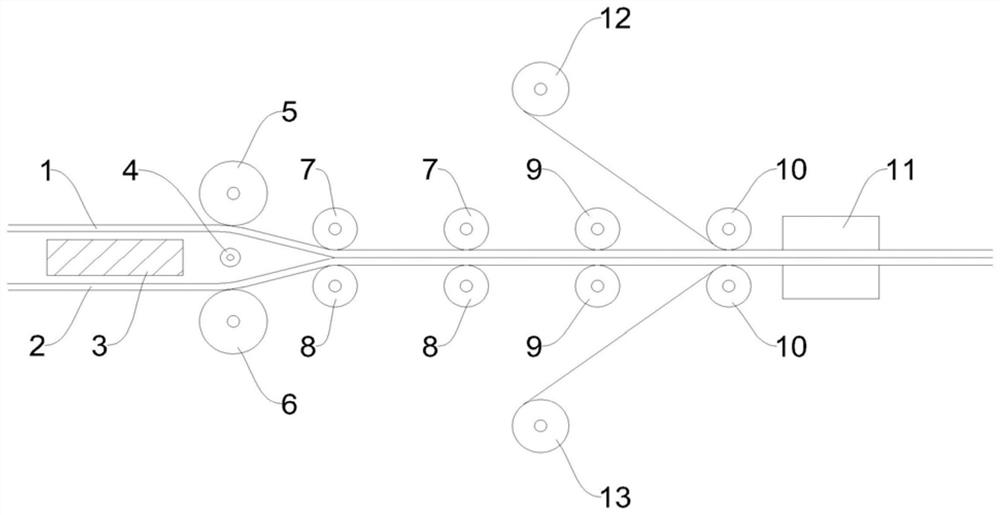

[0029] A kind of preparation method of recyclable reinforced foam sheet packaging material, such as figure 1 As shown, it mainly includes the following steps:

[0030] (1) The upper PS foam board and the lower PS foam board are prepared by foaming process; the upper PS foam board can be flat or rolled.

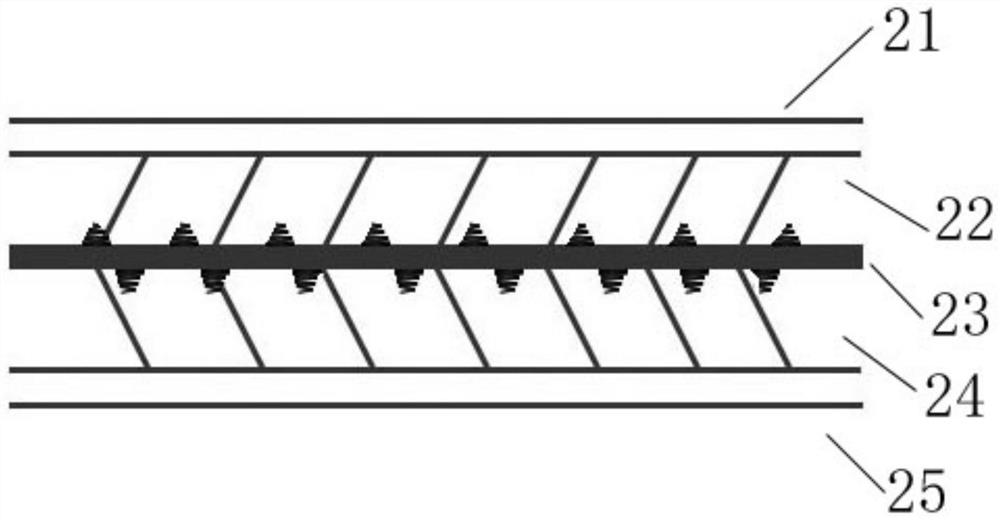

[0031] (2) Composite by corona composite process: a high-voltage discharge rod is set between the upper and lower insulating rollers, and the high-voltage discharge rod is used to generate corona through the controller. The upper foam board is placed between the upper insulating roller and the high-voltage discharge rod. The lower foam board is placed between the lower insulating roller and the high-voltage discharge rod, and the lower surface of the upper foam board melted by corona discharge and the upper surface of the corresponding lower foam board pass through the corona heating zone and are pressed together by the compound roller simultaneously. A heat permeable layer i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com