Model model forming process

A molding process and model technology, applied in the field of molding process of mannequin models, can solve the problems of high maintenance cost, low production efficiency, large environmental damage, etc., and achieve the effects of low maintenance cost, high production efficiency and low transportation cost in the later stage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

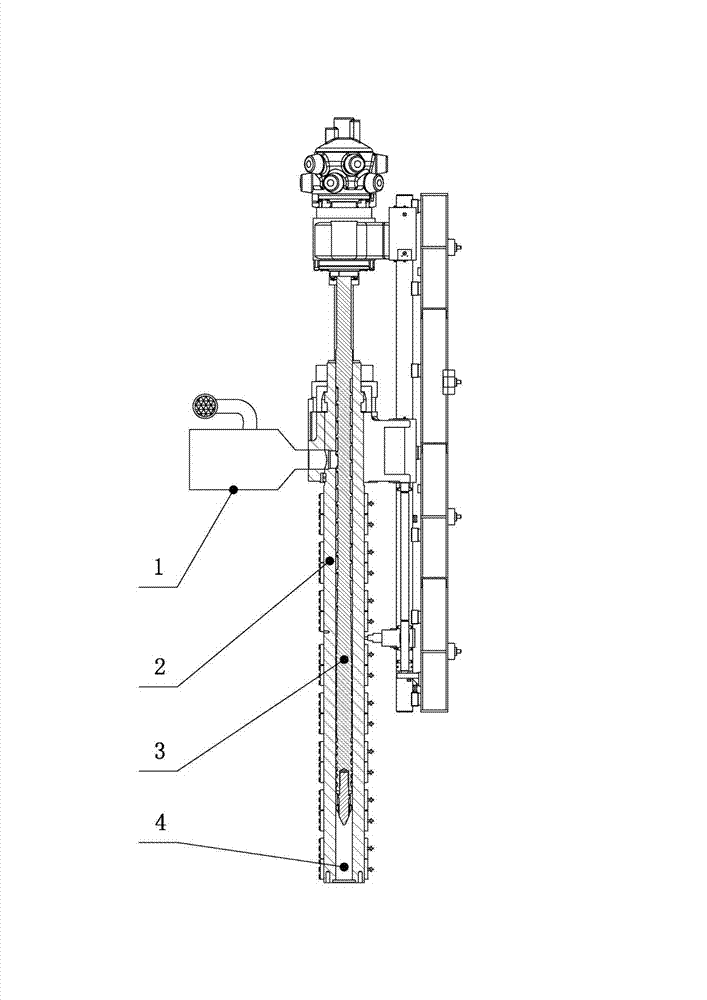

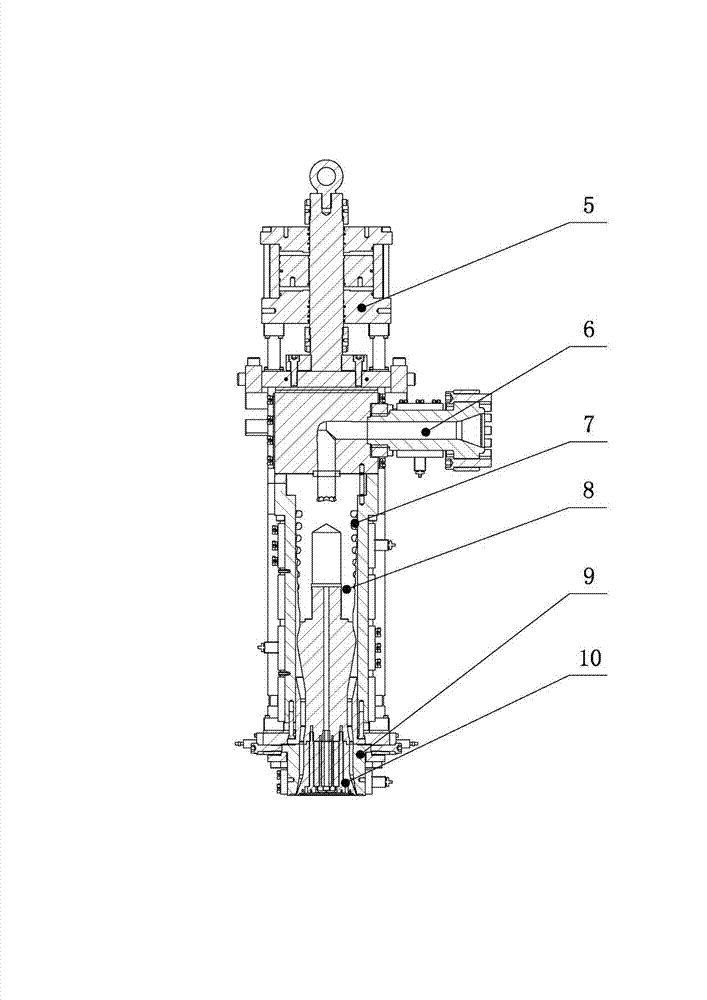

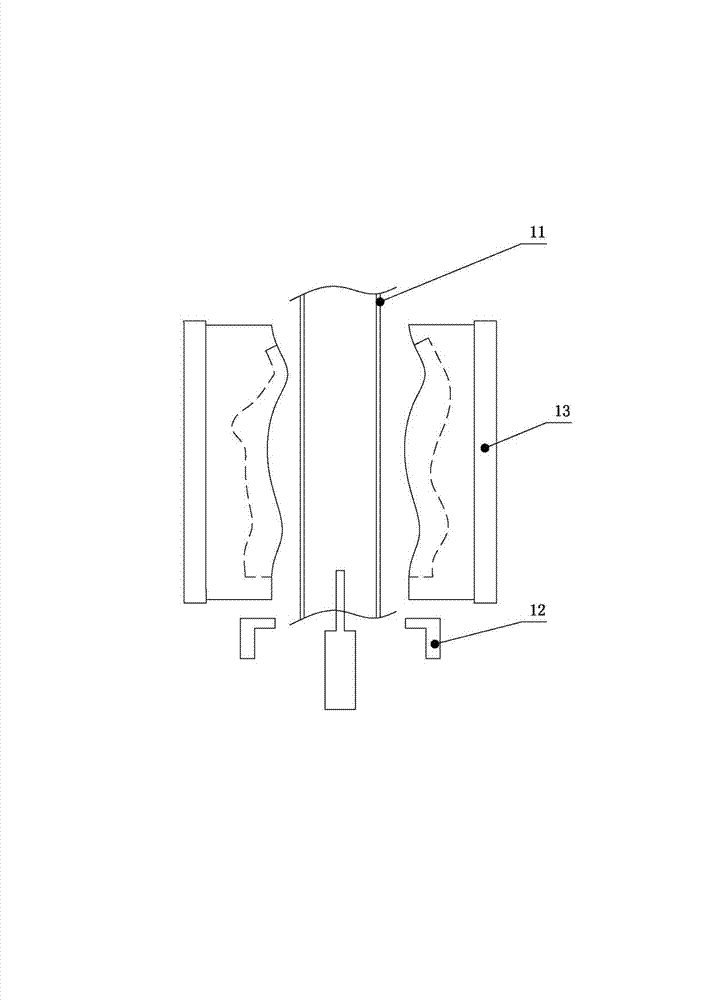

[0017] In order to facilitate the understanding of those skilled in the art, the present invention is described in detail below. The process of the present invention mainly uses a hollow blow molding device, which is an open existing equipment, as attached figure 1 , 2 As shown, it mainly includes a drying hopper 1, a barrel 2, a screw 3 and a melt storage chamber 4. The screw head mainly includes a wall thickness controller 5 , a main channel 6 of the machine head, a spiral runner 7 , a spiral mandrel 8 , a die 9 and a mandrel 10 .

[0018] The molding process of this model model mainly includes the following steps:

[0019] (1) Pour the polycarbonate compound into the drying hopper 1, and carry out drying treatment in the range of 100-140°C for 4 hours. For example, the drying treatment can be performed at a temperature of 100° C. for 4 hours, or at a temperature of 120° C. for 4 hours, or at a temperature of 140° C. for 4 hours.

[0020] (2) After the rubber material is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com