Metal cutting wire with spiral wave-shaped rotary bending parts

A bending part and wire technology, which is applied in the field of composite rotating waveform cutting wire, can solve problems such as metal monofilament breakage, jewel line mark defects, affecting cutting speed and slicing quality, and achieve the goal of improving surface quality and reducing wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

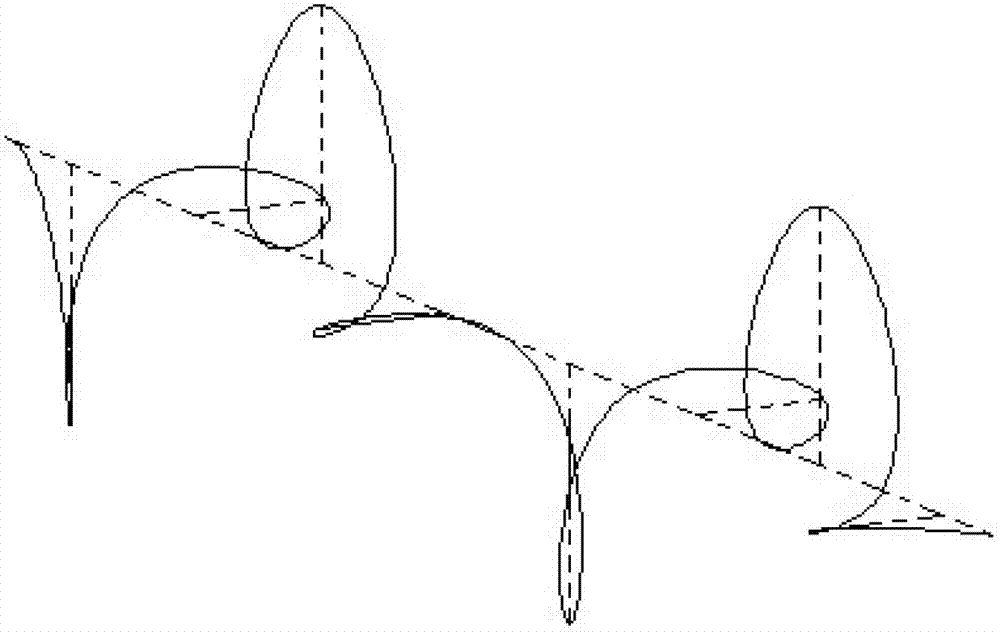

[0022] Such as Figure 1~2 As shown, a cutting wire with a helical wave-shaped rotating bending part has a diameter of 0.115mm and is provided with a plurality of spiral-wave rotating bending parts along the central axis. There are two types of rotating bending parts, and the two rotating The wave heights A1 of the bending part are different, respectively 0.23mm and 0.575mm; and the wavelength W of a single rotating bending part is 3.6mm, the rotating bending parts of the two different wave heights appear alternately, and the rotating bending part is farthest from the central axis The vertical line from the point to the central axis is evenly distributed along the meridian direction of the central axis, such as figure 2 As shown, the four vertical lines in one cycle are in the shape of a cross, and their included angle is 90°.

Embodiment 2

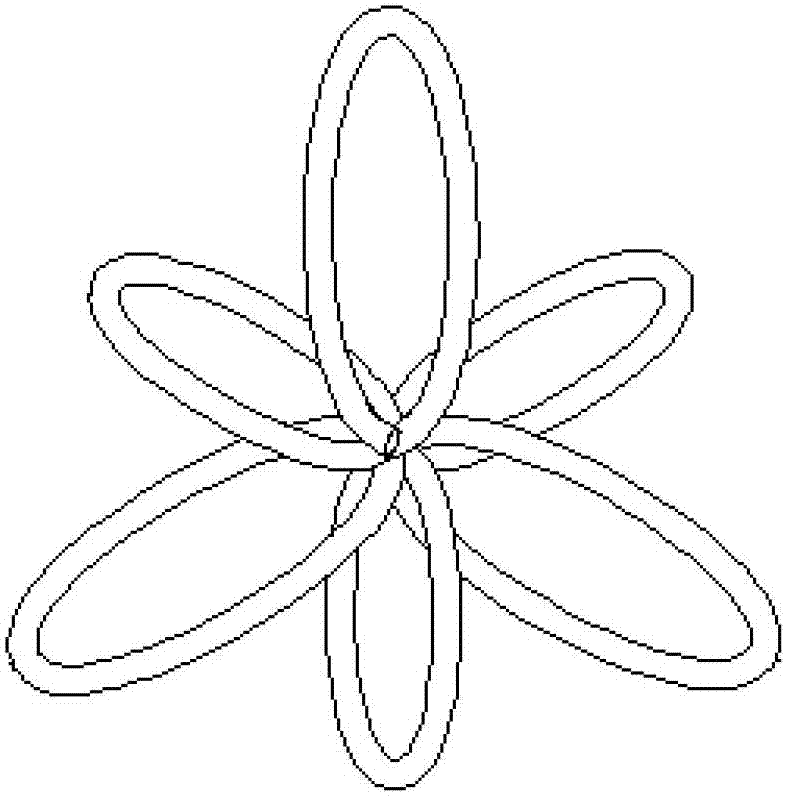

[0024] Such as image 3 As shown, the cutting wire in this embodiment is provided with two kinds of rotating bending parts with different wave heights A1. The perpendicular line from the farthest point of the axis to the central axis is evenly distributed along the meridional direction of the central axis, such as image 3 As shown, the 6 vertical lines in one period are evenly distributed, and the angle between them is 60°; the diameter of the metal wire is 0.25mm, and the wavelength of a single rotating bend is 5mm.

Embodiment 3

[0026] Such as Figure 4 As shown, the difference between the cutting wire in this embodiment and Embodiment 2 is: the diameter of the wire is 2mm, the wavelength of a single rotating bending part is 15mm, and the values of two different wave heights A1 are 4mm and 10mm respectively, and There are 8 single rotating curved parts in one cycle, and the included angle between the farthest point of each rotating curved part from the central axis and the perpendicular to the central axis is 45°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com