Method for extracting polyphenol from Calophyllum Inophyllum L

A technology of sea red fruit and red fruit, applied in the field of polyphenol extraction, to achieve the effect of simple process, easy industrial production, and enhanced antioxidant activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

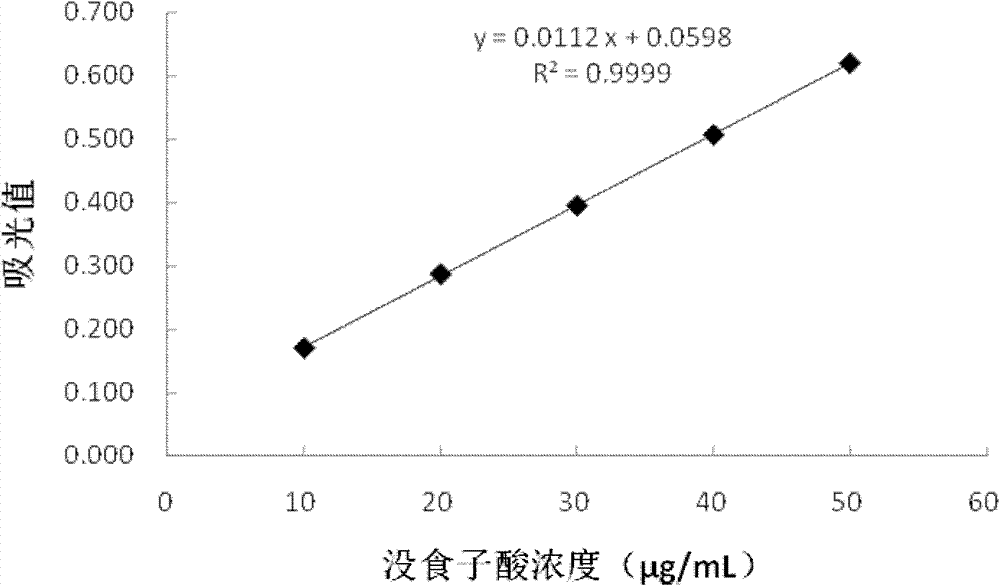

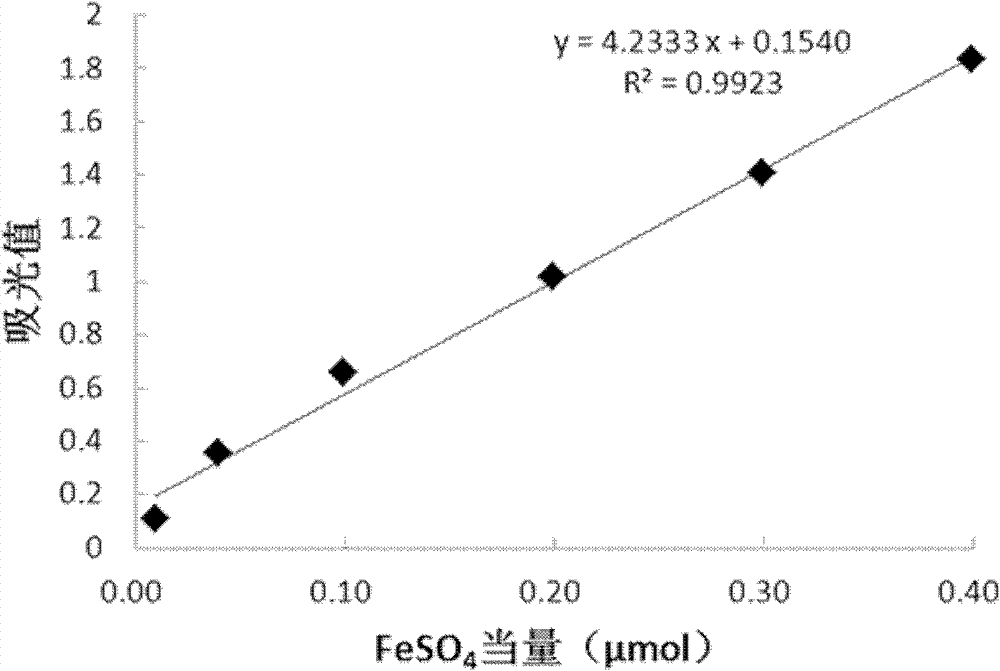

[0042] The sea red fruit was pitted and beaten, 40g of sea red fruit pulp was weighed, and 400 mL of 60% ethanol aqueous solution was added, mixed, and leached in a water bath at 80°C for 3 hours, cooled to room temperature, filtered, and the residue was extracted by repeating the above steps once . The two extracts were combined and concentrated to 1 / 4 of the original volume at 45°C and a vacuum of 0.1 MPa. The concentrated solution was pumped into the balanced NKA-9 macroporous resin column (produced by Beijing Kebao Biotech Co., Ltd.) at a flow rate of 1 mL / min. First rinse the column with 5 times the column volume of distilled water, then use 3 times the column volume of 60% ethanol aqueous solution to elute at a flow rate of 2 mL / min, collect the eluate of 60% ethanol aqueous solution, and depressurize at 45°C and 0.1 MPa concentrate. The concentrated solution was freeze-dried at -60°C and 20 Pa to obtain 0.35 g of pink sea red fruit polyphenol powder, in which the polyp...

Embodiment 2

[0048] The sea red fruit is pitted and beaten, 40g sea red fruit pulp is weighed, and 500 mL of 50% ethanol aqueous solution is added, mixed, and then leached in a 75℃ water bath for 5 hours, cooled to room temperature, filtered, and the residue is extracted once by repeating the above steps . The two extracts were combined, concentrated at 45°C and a vacuum of 0.1 MPa to remove ethanol, and the polyphenol aqueous solution was pumped into the balanced NKA-9 macroporous resin column at a flow rate of 2 mL / min. First rinse the column with 5 times the column volume of distilled water, then use 3 times the column volume of 60% ethanol aqueous solution at a flow rate of 2mL / min, collect the 60% ethanol eluate, concentrate under reduced pressure at 45℃, 0.1MPa, and concentrate The liquid was freeze-dried to obtain 0.33 g of pink sea red fruit polyphenol powder, in which the polyphenol purity was 78% and the FRAP value was 20.03.

Embodiment 3

[0050] The sea red fruit is pitted and beaten, 40g of sea red fruit pulp is weighed, and 600 mL of 50% ethanol aqueous solution is added, mixed, and then leached in a water bath at 85°C for 2 hours, cooled to room temperature, filtered, and the residue is extracted once the above steps . The two extracts were combined, concentrated at 45°C and a vacuum of 0.1 MPa to remove ethanol, and the polyphenol aqueous solution was pumped into the balanced NKA-9 macroporous resin column at a flow rate of 2 mL / min. First rinse the column with 5 times the column volume of distilled water, then use 2 times the column volume of 50% ethanol aqueous solution at a flow rate of 2mL / min, collect the 50% ethanol eluate, concentrate under reduced pressure at 45℃, 0.1MPa, and concentrate The liquid was freeze-dried to obtain 0.30 g of pink sea red fruit polyphenol powder, in which the polyphenol purity was 80% and the FRAP value was 20.51.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com